Humanoid robots, or mobile manipulation robots (MMRs), can help cross the islands of automation normally filled by people to help address the continued labor and skills gaps.

Robotics insights

- The robotics industry has evolved significantly, driven by AI, vision systems and affordability, yet human involvement remains crucial for seamless automation.

- Mobile manipulation robots (MMRs) can bridge automation gaps, with versatility and scalability, though they do require careful planning and a safety plan.

The robotics industry has seen major growth and maturity in the last decade. Technology advances such as vision systems and computing power along with the rise of artificial intelligence (AI) has helped the industry grow in many ways. Robots also are getting cheaper and more affordable. Robots are taking a greater role and improving automation in many ways, but what’s the next step?

Melonee Wise, chief product officer of Agility Robotics, outlined why humanoid robots, or mobile manipulation robots (MMRs), are the next step, in her presentation “The Next Frontier of Automation: Mobile Manipulation Robots (Humanoid Robots)” at Automate 2024 in Chicago.

She said robotics advances, which started in 1961 with the Unimation ARM and on through to today, “Has created highly specialized automation that has driven us to automate these workspaces.”

While that’s great, there’s still a catch: People are needed to connect these islands of automation. Everything grinds to a halt otherwise.

“We still need a lot of people,” she said, referencing how there are more than 1 million unfilled positions. Manufacturers and other industries have spent more money into robots, but the people part of the equation remains a sore point.

“That’s part of the reason why we’ve seen a continuing need for new automation technology,” she said.

Four steps for MMR deployment

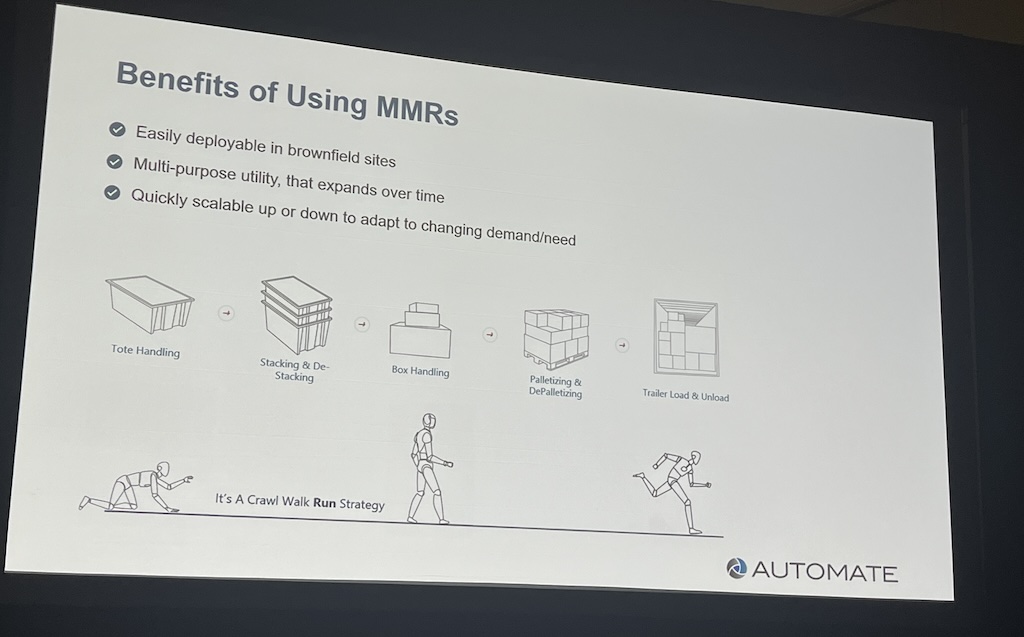

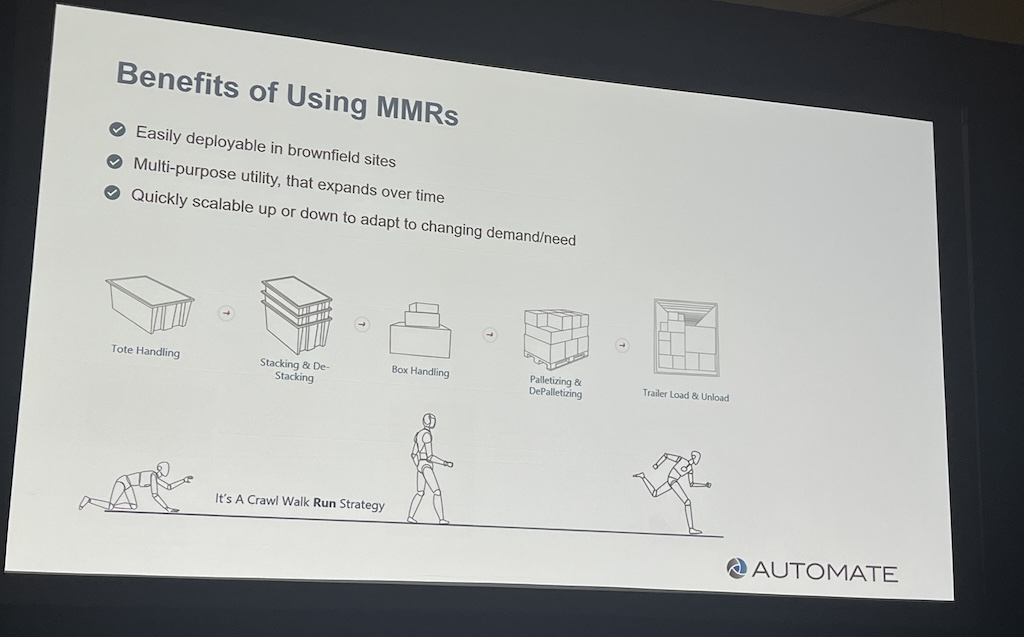

Wise said MMRs provide an opportunity to address these gaps between islands of automation and tackle workflows that need more flexible automation. They can be deployed in brownfield sites and have a multi-purpose utility that expands over time and they’re quickly scalable.

“They’re the perfect partner for other existing automation technology like automated storage and retrieval systems (AS/RS) and other autonomous mobile robot (AMR) technology,” Wise said.

MMRs are useful in several different workflows because they’re generalizable. Users can move the robot skill to many different applications by manipulating the robot so it can do what the user needs it to. These tasks include tote stacking, line feeding, AMR loading and unloading and putwalls. These tasks generally need humans to get objects from point A to point B, but an MMR can bridge that gap without disrupting production.

Like any new implementation in a manufacturing (or any) facility undergoing this kind of change, a solid plan needs to be in place. Wise highlighted four steps any company should take before bringing MMRs into their facility:

-

Gather valuable data during a site visit.

-

Assess the specified operating environment.

-

Design a deployment and adjust along the way.

-

Deploy the MMR in a safe and efficient manner.

Wise expressed the importance of safety, saying, “One of the next things we’ll see with MMRs is the real practical application of safety.”

That’s important because unlike a traditional robot, a mobile robot’s standard operating environment (SOE) is the entire facility. For a mobile robot, this can raise concerns about uneven surfaces, keep out zones, object avoidance, lighting and clearance. However, Wise said an MMR can avoid these issues because they are bipedal and have the technology and sensors to operate safely the way a person would.

MMRs might not be able to talk like C-3PO from Star Wars, but they’re definitely capable of bridging some of these labor gaps while creating a more automated and autonomous world to meet consumer needs.

Chris Vavra is senior editor, Control Engineering, WTWH Media LLC.