Creating a digital thread that provides users with all needed information will help them make better decisions and give their products a longer and more productive lifecycle.

Digital thread insights

- Companies and consumers demand as much access to information as possible, and demand is increasing as technology improves.

- The digital thread can connect the digital and physical processes of a product’s lifecycle, but information siloing remains a challenge.

- Companies seek to improve productivity will only go as far as their products can enable them to go.

Technology is changing how products are being bought, purchased and interacted with and these advances are happening at an exponential rate. This growth, which didn’t seem possible a few years ago, is fueling a boom that is having major impacts, said Leslie Paulson, DVP, general manager, Servigistics Business Unit, PTC, at LiveWorx 2023 in Boston, in the presentation “Powerful Digital Threads Deliver Peak Service Outcomes.”

Advances are happening in “Everything from computing power to the changes in connectivity in the world, advances in artificial intelligence (AI) and more. It really is coming at an exponential rate, and it’s democratized. ChatGPT, for example, is available to anyone. It’s ubiquitous. And the rate of advance are going to increase as we get closer to quantum everything.”

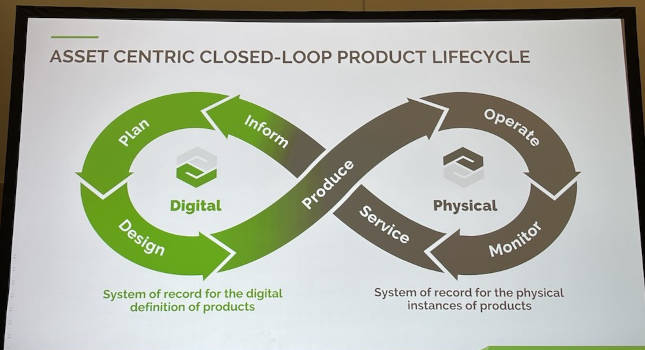

These changes go beyond technology developments, Paulson said. There’s a greater emphasis and focus on the customer in the product lifecycle. The lifecycle, she said, is a critical aspect of the digital thread, which covers the physical aspect, as well, and both feed off one another in a double loop.

“The companies that can glean the most insight across the digital thread will serve their customers better,” she said.

Breaking down the information silos in product lifecycles

The digital thread is designed to cut across an entire product’s lifecycle from conception to design to service. This is not always easy to accomplish, Paulson said, because information siloing remains a hurdle.

“Those silos are real. We need to work across these functions. If we did something better and the people responsible know what they need to know, wouldn’t we make better decisions?”

This is especially true with the services side of things, which plays a larger part of the asset’s lifecycle, Paulson said. “There are events that happen during the asset’s lifecycle, and we need to understand it because otherwise we won’t service it well.” The added benefit, she said, is by keeping an asset in service for as long as possible exponentially improves its value over the long term. That’s only possible if all the information is accessible.

Going beyond the individual asset, this can be applied to the entire service landscape, and it can be integrated.

“There’s a lot of capability and tools that can drive powerful results,” Paulson said. “At the beginning, though, we have to deliver the basic information points, and we need to be able to optimize the service parts in a way so the right part is in the right place,” Paulson said. “We have to maximize availability and minimize costs.”

Paulson said companies will fare best if they empower the critical stakeholders with the right information.

Managing and connecting things for better data capture, integration, use

Aly Pinder, VP, IDC aftermarket services strategy, said companies’ main priorities remain efficiency and satisfaction. This is even more important, he said, as companies realize they need to improve customer service and employee experience. That’s not always easy because there are worker shortages and other challenges that limit companies from sometimes reaching their full potential.

The challenge, Pinder said, is more than half of devices are not connected. “The goal is to get more connected, but how do we get there, and what do we once we get it?”

Pinder mentioned how companies can go from a break/fix reactive mindset to a prescriptive mindset. He said it’s not practical for all companies to go prescriptive, but they should strive to be more in that direction along with predictive and preventive.

“If you’re going to be reactive because it works, [then] be better” while doing so, Pinder suggested. “Make sure the worker has all the info” needed.

Information is one of the most — if not the most — valuable commodities, but Pinder said that is only part of the equation. If the information is siloed and restricted, then it doesn’t matter much. The same is true when it comes to creating a service model that maximizes the value of the products. He encouraged companies to start now and focus on the short-term wins with an eye toward the long-term transformative views.

“If you have data, it’s only as valuable as the people who have access to it.”

Chris Vavra, web content manager, CFE Media and Technology, [email protected].