Non-profit Connecticut center shows manufacturers how to design, optimize and virtually commission operations using digital twin technology with 3D simulation software with time savings of 50% to 80%.

Digital twin, simulation insights

- CCAT, a non-profit organization based in East Hartford, Connecticut, provides free consulting, validation and funding support to help small- to mid-sized manufacturers adopt advanced manufacturing technologies and automation.

- Digital twin and simulation technologies save manufacturers time and preserve process knowledge.

- 3D simulation and robot offline programming allow companies to design, validate and optimize manufacturing processes virtually.

Simulation and digital twin technologies are helping small manufacturing business advance more quickly, including for offline robotic programming. The small and mid-sized business model (SMB) allows manufacturers to adapt quickly to a variety of circumstances and conditions. At the same time, an SMB’s agility can come at the cost of limited resources to keep abreast of the latest technology. With tough production schedules that require all hands-on deck, there’s often little time to explore how to do things better.

The East Hartford-based applied technology and training non-profit Connecticut Center for Advanced Technology (CCAT) steps in to fill the automation technology gap for SMBs. Driven by the mission to lead the advancement of applied technologies, power the workforce of the future and inspire change, CCAT serves as a technology consultant that elevates U.S.-based manufacturers to perform better and more profitably, including smaller original equipment manufacturers (OEMs).

Automation advice helps small and mid-sized manufacturers

“OEMs and larger companies have dedicated teams who research, evaluate and advise on what technologies they should adopt to make them more competitive,” said CCAT principal engineer, Nasir Mannan. “Small and medium-sized shops rarely have that capability, mostly because they’re concentrating on getting parts out the door. We invest time to research, demonstrate and validate advanced technologies because they do not have it to spare.”

Established in 2004, CCAT advises hundreds of companies annually throughout the United States on how to implement technology and automation that will make them more productive, competitive and produce parts at a lower price point. Though it’s located in a hot bed of advanced manufacturing for the government, with Sikorsky, General Dynamics Electric Boat, Pratt & Whitney and others as neighbors, CCAT’s services are industry agnostic, serving a variety of companies with a workforce between three and 300 employees.

In addition to consulting on the best technology and automation solutions for a company’s needs, CCAT provides a variety of funding and grant mechanisms that help SMBs take advantage of the latest technological advances and developments.

“Manufacturing companies can look to us as neutral applied research and development team of engineers and scientists. We don’t sell anything. In fact, we give out state and federal funding for U.S. companies to reduce the cost of purchasing the technologies that we’re showing,” Mannan said.

Through seminar presentations, trade and technology shows and direct inquiries, SMBs receive CCAT recommendations, technology validation and adoption assistance that can make them more profitable.

3D simulation software for manufacturing design, optimization, virtual commissioning

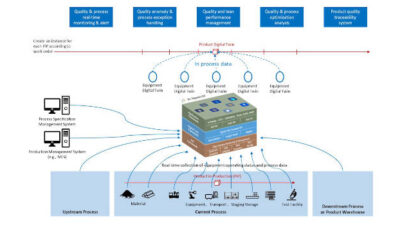

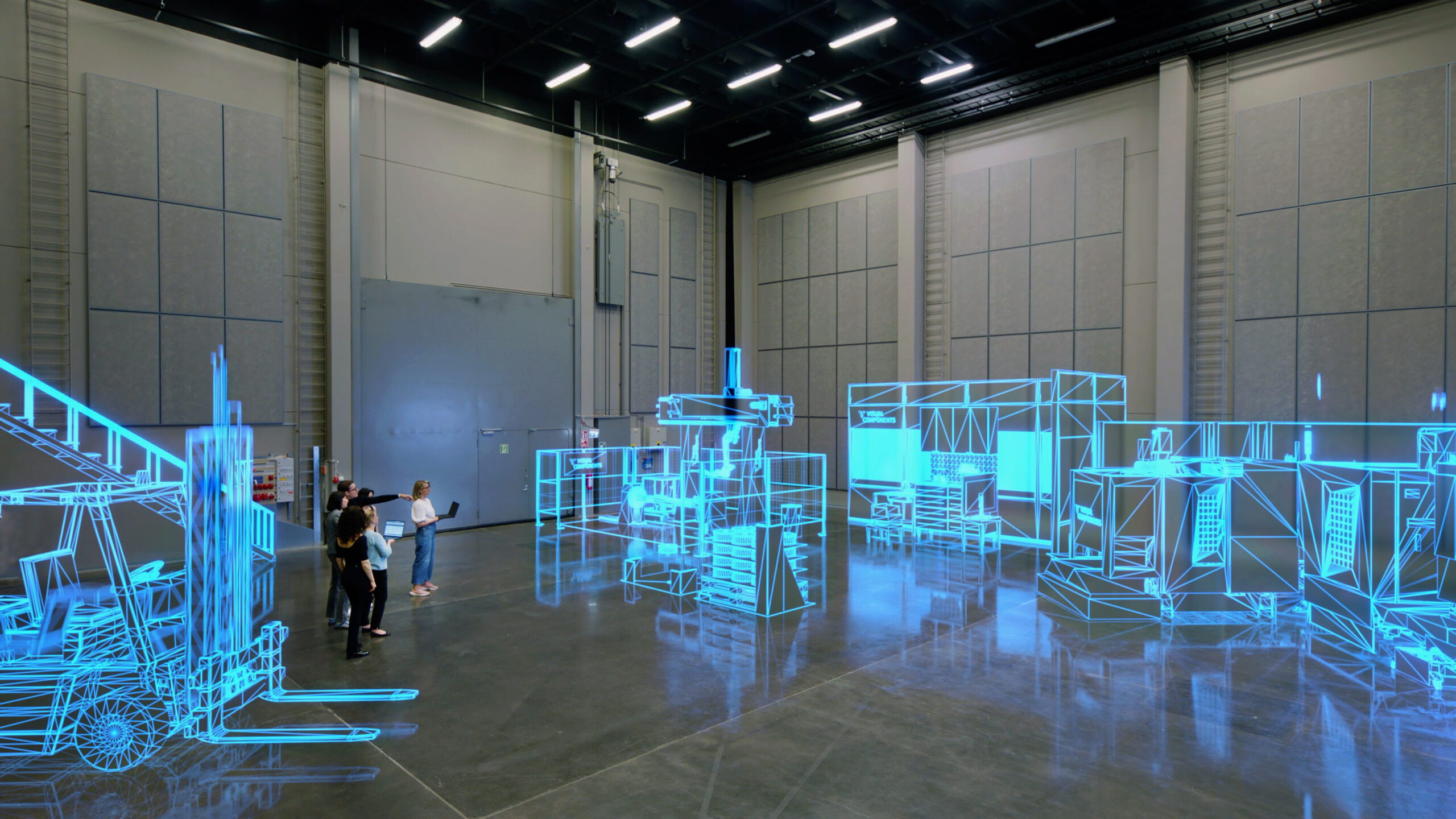

For example, a technology CCAT recommends is 3D simulation software, which allows manufacturers to design, optimize and virtually commission operations using digital twin technology. A digital twin rendition of factory processes reflects real-time production environments, including the facility’s best practices and detailed operations, personnel, specific equipment and controls.

Virtual 3D pre-commissioning software can include robot offline programming (OLP). With OLP, SMBs can program, configure, test and validate the performance of specific robots in their operations without interrupting production. OLP programs can enable manufacturers to program robots using 3D CAD data that is downloaded to the robot.

“It can be overwhelming for smaller companies to think about how technologies like OLP and simulation can help them thrive tomorrow when the top priority is to survive today,” Mannan said. “We distill the information, make it accessible and show how easy it can be.”

Simulation software shows specific gains for manufacturers, helps skills gap

With 3D simulation software, CCAT can show SMBs how to optimize processes with certainty without losing valuable time to install, test and commission new equipment. Optimization enables companies to produce more, increase efficiencies and improve profits.

“Companies see benefit because they get more than a fictional demonstration,” Mannan said. “The simulation uses their environment, variables and personnel scenarios and shows them the specific gains they can make.”

Additionally, simulation software pushes back on the talent drain currently plaguing the manufacturing sector. Experienced employees are retiring or leaving the workforce and are not being replaced, creating a skills gap. A 2024 study co-conducted by Deloitte and The Manufacturing Institute estimates the current workforce trajectory will leave almost 2 million manufacturing jobs open over the next decade.

Digital twin simulation technology and digital thread workflows allows manufacturing to recover the collective knowledge lost through workforce attrition and capture the logic and parameters of a process – all the factors and decisions that an engineering team might make to obtain a required result. By encoding this “tribal knowledge” into a model-based system, SMBs can save vast amounts of time.

“You can have a new technician or engineer come in, and with a few mouse clicks use programs and parameters the previous user developed,” Mannan said.

Time savings in automation design and programming

Estimations from CCAT indicate that SMBs can save 50% to 80% in time because design and programming functions are cut from hours to minutes and days to hours.

“It’s really quite fantastic,” Mannan said of using digital simulation software. “The first time I saw it I was blown away, and what I wanted to show companies was, look, if you guys don’t know this exists, you should.”

Graham Wloch is director of business development for Visual Components. www.visualcomponents.com Edited by Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected].

Keywords

Workforce development, 3D simulation, digital twin

Consider This

Are you implementing digital twins and simulation to accelerate development and add efficiency?

Online

https://www.controleng.com/system-integration/workforce-development

For more information about CCAT’s mission and resources, go to www.ccat.us.