A dozen years of Industry 4.0 and smart manufacturing efforts have been less effective in continuing the productivity gains of Industry 3.0. Tips and examples show how an industrial transformation strategy can improve industrial productivity and meet industrial sustainability initiatives.

Learning Objectives

- Understand how to facilitate industrial transformation by educating the workforce to change more easily and adapt to uncertainties.

- Benchmark what industrial transformation winners are doing, including Lockheed Martin, Tesla.

- Create changes needed for industrial transformation, digital transformation, sustainability.

Industrial sustainability, industrial transformation insights

- Facilitate industrial transformation by educating the workforce to change more easily and adapt to uncertainties.

- Improve industrial transformation by benchmarking what industrial transformation winners are doing, including Lockheed Martin and Tesla.

- Understand how to create changes needed for industrial transformation, digital transformation and sustainability.

Future operations can profit with more productivity as well as sustainability efforts by taking “The Journey to Zero+” on the way to 2030, as explained at LNS IX2023, The Industrial Transformation Event. The in-person and online event from LNS Research included a keynote session that explained the zero+ concepts and benefits and provided guidance and tips for industrial transformation.

Vivek Murugesan, senior research associate, LNS Research (Figure 1), said that beyond just sustainability goals, organizations need to consider zero harm, waste and net carbon while making step changes toward productivity gains because it’s the right thing to do, it creates profits and helps with long-term survival. Automation and digitalization can help the required industrial transformation. Speakers in the session were:

-

Matthew Littlefield, LNS Research co-founder, president, and research leader

-

John Genovesi, president and EVP of enterprise software and advisory, UL Solutions

-

Ellis A. Jones, sustainability leader and independent director, Timken Steel Co.

Educate the workforce to change more easily, adapt to uncertainties

Murugesan acknowledged that change can be challenging. People change because they believe in the vision and in their leaders. Aligning people to changes envisioned in an uncertain world can increase challenges. An educated workforce is easier to change, Murugesan said, and research can help prioritize what changes should happen when and how (Figure 2).

Littlefield (Figure 3) began by highlighting unexpected events that changed markets globally including continuing of the war in Ukraine, a Middle East war, price controls on drugs from the Inflation Reduction Act of 2022, inflation trending down and interest rates remaining high, organized labor making gains, pushback and politicization of environmental, social and governance (ESG) and diversity, equity and inclusion (DEI) efforts and the mainstreaming of generative artificial intelligence (AI).

LNS Research shows that only 12% of companies surveyed do not have an industrial transformation initiative in 2023, down from 39% in 2015; 54% have active initiatives in 2023, compared to 38% in 2015 (Figure 4). Three significant issues for industrial companies are hiring, scaling quick wins and front line and plant manager buy-in (Figure 5).

Why benchmark what industrial transformation winners are doing?

Industrial challenges are real, Littlefield said, with manufacturing productivity flatlining since 2011, despite Industry 4.0 and smart manufacturing efforts (Figure 6). In addition, he said safety improvements and quality also are flat-lining, all demonstrating that manufacturing is “hitting limit of existing approaches.”

In an effort to more consistently measure productivity efforts and help leaders improve, LNS Research is launching a productivity index in 2024. The graphics (Figure 7) show 156 publicly traded companies in 8 sectors, measuring plant, property and equipment along with other metrics. As a whole the companies show about 1% growth from 2012 to 2022, but breaking out 8% of the companies shows a considerably different picture in long-term growth in productivity and revenue with 2.58% compound annual growth rate over 10 years. Those left showed a fractional decrease for the same period. Looking at similarities in these pathfinders can help others to improve, Littlefield said.

Lockheed Martin, Tesla benefited from industrial digital transformation

Littlefield cited two examples, Lockheed Martin and Tesla electric cars, leading in industrial transformation efforts.

During the 2012 to 2022 period, Lockheed Martin increased productivity by 16%, production by 27% and units of profit by 140% by creating a next-generation software-enabled products, configured to order, implementing a long-term service model, greenfield facility investments and digital twin, digital thread, industrial Internet of Things and industrial transformation.

Tesla electric automobiles, 2012 to 2022, showed increases of 22% in productivity, 16,573% in production and 234% in units of profit. It also created a next-generation software-enabled product, simplified mechanical components, implemented fewer model changes, used a direct-to-consumer sales model, made greenfield facility investments and embraced industry 4.0 and industrial transformation.

Create success in industrial transformation, digital transformation, sustainability

“What can you do to drive change?” Littlefield asked. Industrial transformation efforts, including industrial digital transformation, industrial sustainability and zero-plus efforts, benefit with naming and branding, by setting goals and targets and by refreshing and realigning goals. Strategic initiatives should be aligned to support the overall strategy (Figure 8), integrating with the broader value chain.

“What makes success?” he asked. The company operating model needs to optimize productivity with a clear understanding of the platform, with a balance of value preservation and creation. Many fail to scale. Technical feasibility must be demonstrated with pilot testing to show how people and processes change to support the new technology. Buy-in is required from the profit and loss (P&L) leader in the organization to sign, invest and own the initiative.

Using industrial sustainability as a tool for industrial transformation

Genovesi looked at ways to use sustainability as an industrial transformation tool. It’s possible to reexamine and reapply industrial transformation by looking at opportunities in manufacturing, automation, industry 4.0 and industrial transformation. Many opportunities exist for sustainability to support other efforts while doing something good for humanity.

Safety has evolved considerably in the 130-year history of UL, and UL Solutions helps with sustainability efforts, Genovesi said. While sustainability has become highly politicized globally, he said, “We can take advantage of it to drive operational improvement.”

Consumers expect more information about the products they purchase, and industrial sustainability efforts can help provide that.

Common industrial challenges Genovesi sees include: Sustainability, supply chain performance, training and skilled labor and digital transformation. Industrial companies are investing $500 billion per year in digital transformation initiatives, he said. Next is sustainability transformation.

About half of industrial sustainability translates into a competitive advantage because of reduced costs and waste, improved reputation and branding along with a decrease of enterprise risks.

Genovesi said financial impacts can be significant (Figure 10). Nestle reduced water consumption 41% and increased production 73% since 2000. Kaiser Permanente 8% energy savings translated into $19.6 million savings per year.

Compliance and cost avoidance for the supply chain focuses on formulations used for products and delivered as part of ESG reporting.

Kroger’s efforts to sell sustainable products increased product compliance rate increased to more than 90%; more than 100,000 products have supply chain transparence and compliance.

Nestle improved data capturing at 1400 sites’ efforts in 100 countries to meet local regulatory requirements resulted in a payback of months for the required investment.

Industrial leaders need to take action for industrial sustainability

Jones (Figure 11) said we’re at a tipping point in industry, when leaders must take action.

Figure 11: Ellis Jones, sustainability leader and independent director, TimkenSteel Co. (and 35 years at Goodyear) shared sustainability leadership tips at LNS IX2023, The Industrial Transformation Event. Courtesy: Control Engineering, LNS Research

His advice derived in part from 35 years at Goodyear, including having a top performing plant for safety. To have operational teams understand what’s required for industrial transformation initiatives requires full integration of what it is into what’s being done in the plant. You cannot have soup without the liquid, he said. Safety (or whatever the initiative) is the liquid of the soup.

In your journey to 2030, Jones asked, what’s your liquid? Leaders need to understand that, then influence, connect, integrate and deploy to lead a journey courageously, he suggested.

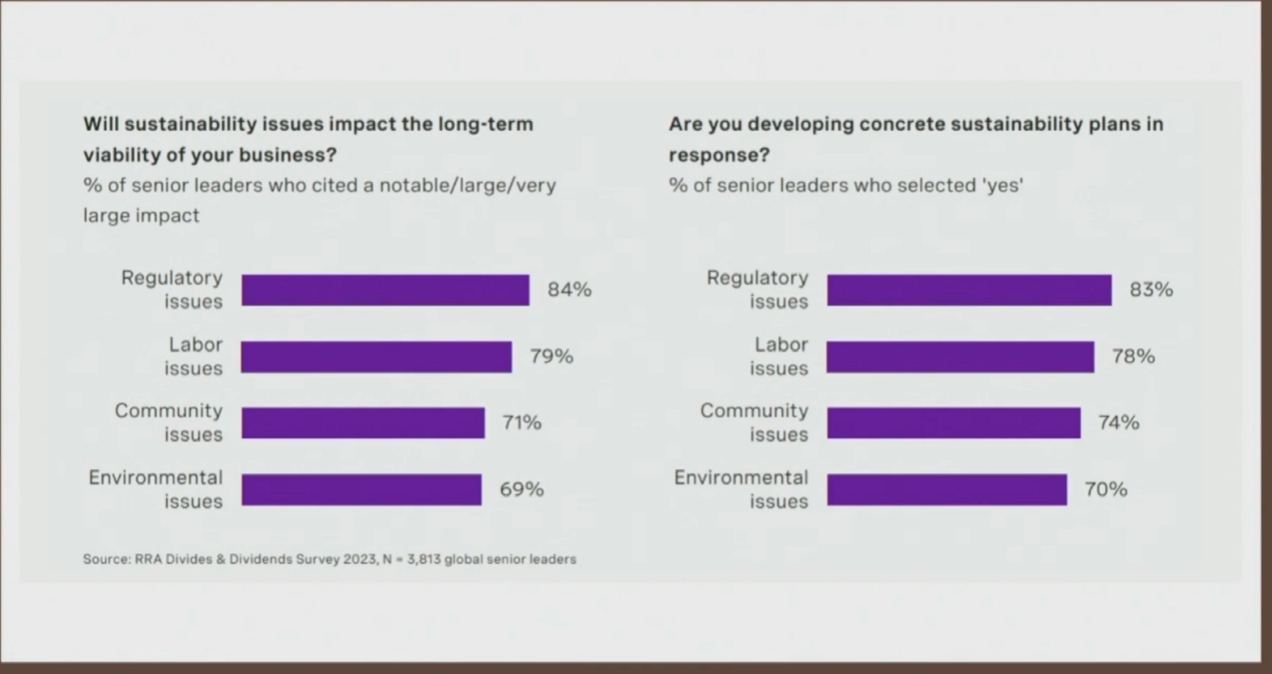

Figure 12 shows motivational, mobilization and accountability gaps among how sustainability impacts regulatory, labor, community and environmental issues and if senior leaders can develop concrete sustainability efforts in response.

Additional advice from Jones included acting on meaningful measurements, starting early, and integrating industrial transformation initiatives into business, strategy, products and compensation. If you’re waiting for permission to begin, Jones said, you already have lost the race. Sustainability is not going away. Don’t be afraid of failure. Be afraid of inaction, Jones said. Lead with courage.

Mark T. Hoske is content manager, Control Engineering, CFE Media and Technology, [email protected].

CONSIDER THIS

Is your organization meeting sustainability goals as part of industrial transformation, or are you stalled?

ONLINE

See more about LNS IX2023, The Industrial Transformation Event from Control Engineering.