Not all artificial intelligence (AI) is built for industrial success. Process manufacturers need AI solutions grounded in first principles — ensuring accuracy, safety and efficiency — while reducing complexity in model design and development.

AI insights

- Not all AI is equal, and industrial processes require some nuance when it comes to AI.

- High-quality data is essential for AI success in industrial applications.

- Models can become AI agents of their own, helping test and refine operations as use-case-specific AI models built for more granular purposes.

There have been few technologies in history that have seen the meteoric rise in popularity that artificial intelligence (AI) has experienced in just the last few years. AI is dominating headlines and one of the key messages that companies are hearing is that they must adopt AI or be left behind.

Process manufacturing is no exception to this trend. Operational technology (OT) teams are bombarded with a vast array of new AI technologies designed to help them better perform their tasks. However, not all AI technologies are created equally, especially when it comes to industrial applications. Selecting fit-for-purpose industrial AI technologies is essential for ensuring safety and efficiency of critical operations.

What is industrial AI?

Both standard and industrial AI use data and machine learning algorithms to solve complex problems quickly. However, industrial applications are regulated by physics, chemistry and thermodynamic principles. Therefore, purpose-built industrial AI is differentiated from standard AI in that the former is bound by first principles models that help train the AI model efficiently and guarantee the results are safe for the plant’s operation.

Immutable first principles constraints — based in detailed physics and chemical data built into the hybrid models — guide and instruct both the way industrial AI models are trained and the potential results those models can generate. Those guardrails create a safety zone where the AI can operate, ensuring the AI does not simulate scenarios or build models the OT team would not want to run because they are impossible, dangerous, or expensive. The world is too big to explore every possibility, so industrial AI’s exploration space is limited to realistic, safe scenarios.

The result of this strategic combination is that industrial AI not only relies upon critical guardrails to limit how the AI can operate, but it also provides clearer guidance for how to most efficiently sample a model, so teams are not required to explore limitless — and often nonsensical — options. Moreover, purpose-built industrial AI enables extrapolation to setpoints where no plant data is available, while eliminating the possibility that the AI tools will generate out-of-bounds recommendations. Ultimately, industrial AI tools help teams more easily and accurately improve their models as they acquire data to drive faster convergence on accurate setpoints for a quicker path to control optimization.

Industrial AI in action

There are a wide variety of use cases for AI tools, but in process engineering, three critical ones have drawn a great deal of attention.

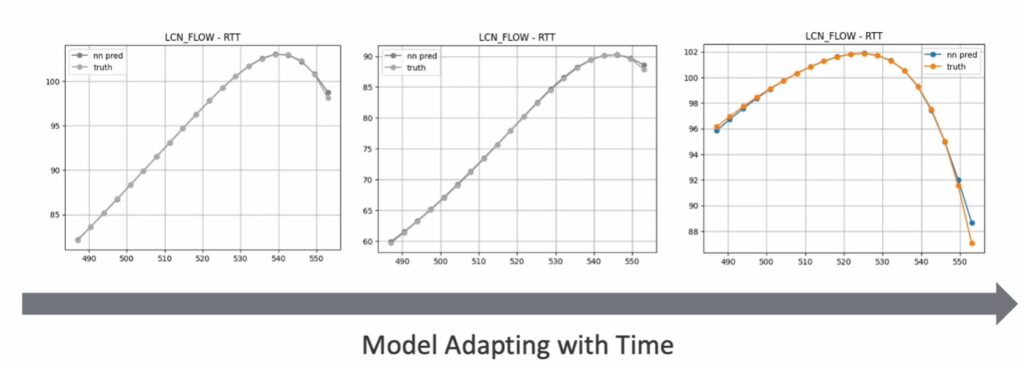

Agility

Process plant operations are complex. Not only must OT teams manage shifting variables (environmental, asset reliability, schedule, etc.), but many must also manage regular changes in production to meet fluctuating energy supplies from renewables, shifting market demands and other variable operating factors. AI tools simplify and strengthen the process of continually refining models to meet operational needs based on real-time observations. Using contextualized data from control, scheduling, asset performance management software and more, OT teams can bring critical information together to help refine models and their associated processes, ultimately leading to better decisions (Figure 1).

Guidance

As OT teams continue to lose experienced personnel to retirement, they also sacrifice decades of institutional knowledge. Modern AI tools provide decision support to newer users as they work to better explore options and adjust process control to improve safety, throughput, efficiency, sustainability and more. AI-based virtual advisors not only unlock vast databases of knowledge, but do so through natural-language interactions, increasing the speed and accuracy of decision support.

Automation

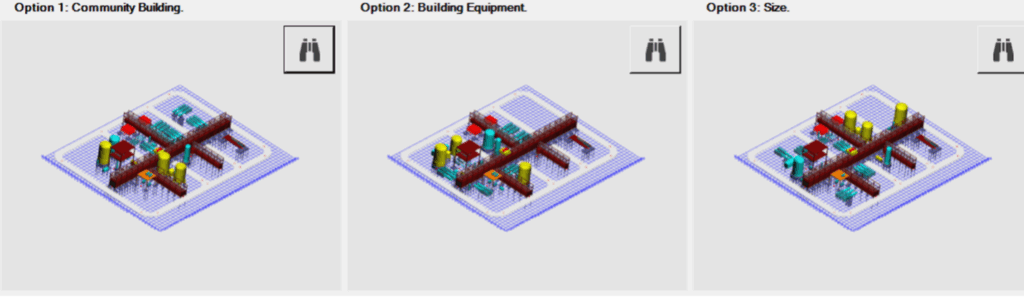

The in-depth consideration of various alternatives and options to identify the best solution or preferred approach to a design is often referred to as optioneering. The use of AI to generate the most effective and efficient engineering options is changing the way OT teams approach process and project design. Instead of working toward a single, optimal design, teams can use generative AI optioneering tools to add more interactivity to engineering processes, empowering them to generate multiple designs more quickly and easily.

Each of the models will have very different characteristics, while remaining within requirements. Further, optioneering enables designers to consider intangible design criteria that are not captured in the typically used simple numerical/categorical specifications, such as long-term reliability, maintainability, compatibility of the design with the rest of plant or other connected equipment and even aesthetics (Figure 2).

Optimized AI agents

One of the key benefits of building industrial AI models generated around first principles is that those models can be delivered by fit-for-purpose AI agents designed to perform exceedingly efficiently and effectively at a given set of tasks.

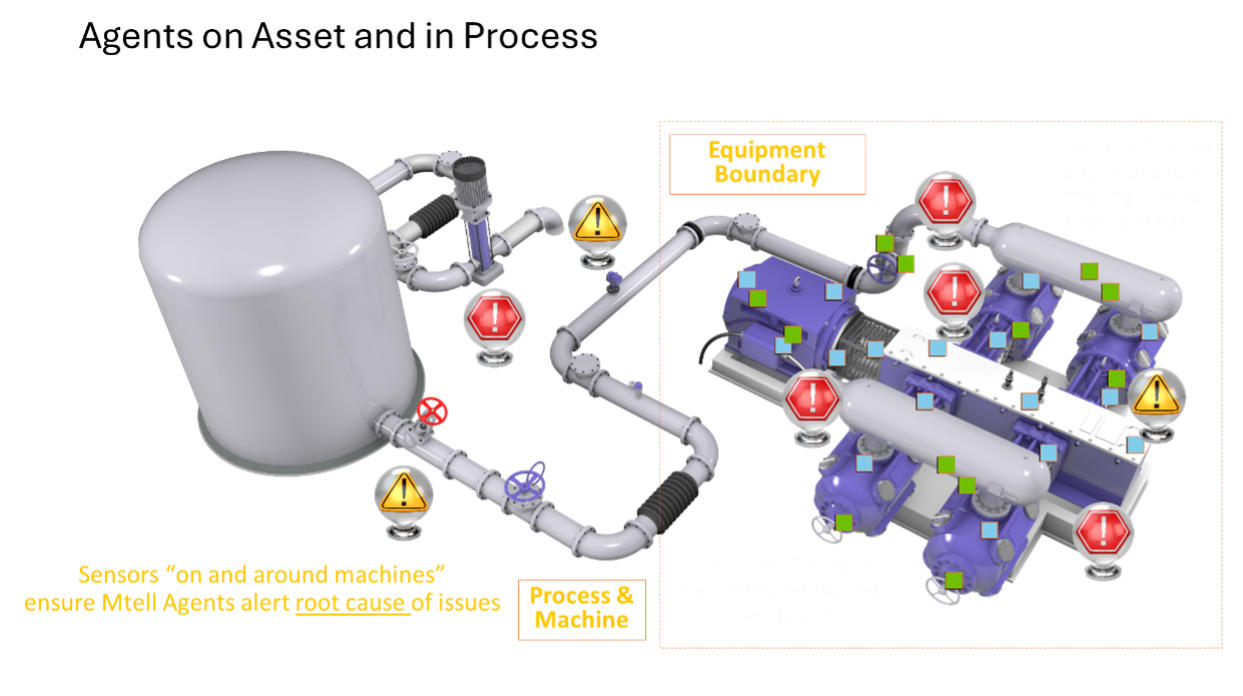

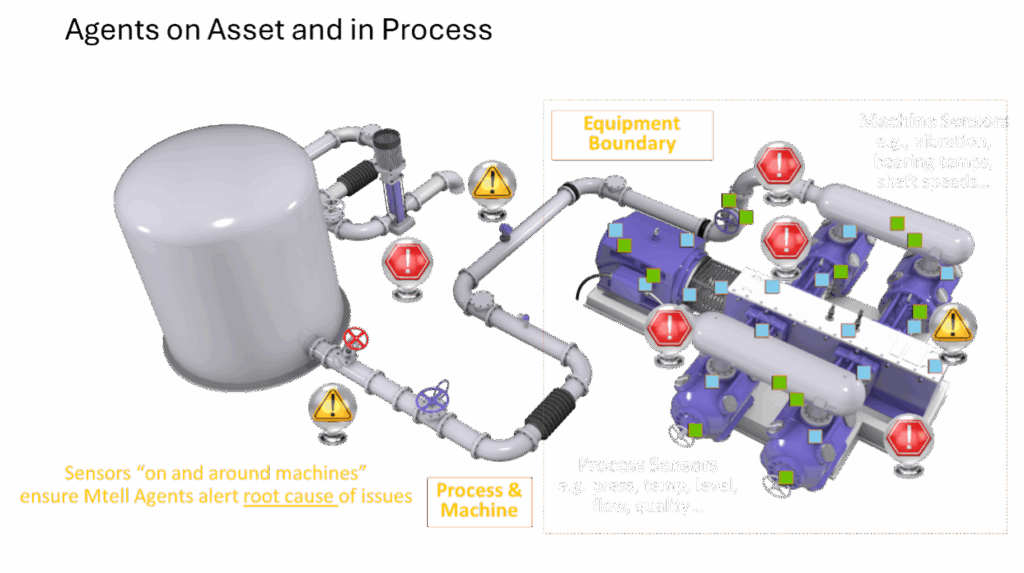

Today, industrial AI agents use specific and relevant data sources to solve a wide variety of problems. A common example is seen in the reliability space, where enterprise-level reliability solutions are seamlessly integrated with predictive and prescriptive asset health software to create comprehensive asset health solutions. These systems rely on fit-for-purpose agents built on extensive failure mode and effects analysis databases to make advanced analytics more intuitive.

AI and machine learning-based reliability agents use pattern recognition algorithms that incorporate multivariate data to predict asset degradation based on embedded domain knowledge. The agents rely on a vast library of existing failure modes and effects — in combination with a wide variety of machinery health and process variables — to identify individual aberrations as part of larger, more serious problems in the plant. Armed with that identification and AI-generated problem-solving steps, reliability teams can quickly intervene to solve the plant’s — or even the enterprise’s — most complex issues.

Similarly, in the operations space, industrial AI agents can also be leveraged for process optimization. As teams engineer processes, industrial AI helps them see multiple alternatives and factor in multiple criteria to develop a range of possibilities to select the best design more easily. With the help of industrial AI, hybrid models have become more robust and compatible with existing equipment and plant designs. As those models are further refined, they can become AI agents of their own, helping test and refine operations as use-case-specific AI models built for a more granular purpose, such as those designed for heat exchangers or distillation columns.

While today’s typical AI deployments tend to be more independent in nature and geared toward their specific area of the plant, the most advanced solutions are evolving toward something more. AI tools for reliability already use data from operational systems to deliver predictive capabilities and vice versa. The future points to a seamlessly interconnected AI workforce, built from individual agents optimized for specific tasks and working in parallel with other AI agents, as well as human operators and technicians.

Drive more value from data

As the AI workforce, human operators, technicians and even executives work together, they will be heavily reliant on high-quality, contextualized data. There is always a difference between simulation and what exists in the plant and industrial AI solutions efficiently use smart data to close that gap. Today’s most effective OT teams are exploring industrial AI solutions that integrate seamlessly with their control systems to provide continual real-time contextualized data so AI agents constantly know the state of the plant and can suggest effective optimization strategies. Moreover, that type of advanced connectivity simplifies change implementation because any optimization strategy the AI generates will need to be performed via the control system. Therefore, the more seamless the connectivity between systems, the easier that process will be when implemented.

Not just any AI

The rise of AI has provided process manufacturers with a wide variety of new solutions for improving performance through a step change in agility, better guidance and improved automation optioneering. However, not every AI solution is appropriate for industrial operations. While unlimited creativity sounds wonderful, truly safe, efficient and effective industrial operations are bounded by the immutable laws of chemistry and physics.

Today’s most effective teams opt for industrial AI solutions which are, by definition, grounded in the first principles that keep hybrid models both accurate and efficient. Such solutions save time and effort by drawing on a deep base of existing knowledge to effectively train models, while also streamlining customization by narrowing optionality.