Forward-thinking organizations extend the value of digital twins by using them to drive collaboration and optimize processes throughout the entire lifecycle of their assets.

Digital twins insights

- Digital twins can provide rapid return on investment when used in lifecycle optimization.

- Digital twins can be employed in the design, testing and training processes in an organization.

- Teams can use digital twins to learn how to use new technologies.

Process manufacturers have increased their need for optimal performance to meet shifting sustainability standards and increasing global competition in the marketplace. To achieve these goals, many have begun to pursue new strategies to drive process improvements. Dynamic simulation has gained traction in recent years — particularly when employed as part of a digital twin. More organizations have recognized the ability of a digital twin simulation to bring critical value to project execution, helping teams more easily engineer and test their processes and equipment well before any physical technology must be purchased or implemented.

The most successful teams have even discovered they can take their project simulations further by using existing digital twins to create operator training simulations. Using these systems, operators can practice new control strategies via interfaces virtually identical to the ones they will see during actual production. By creating this additional critical use case for simulations, most project teams have discovered they can easily make their digital twin simulation technologies pay for themselves with an extremely rapid return on investment (ROI).

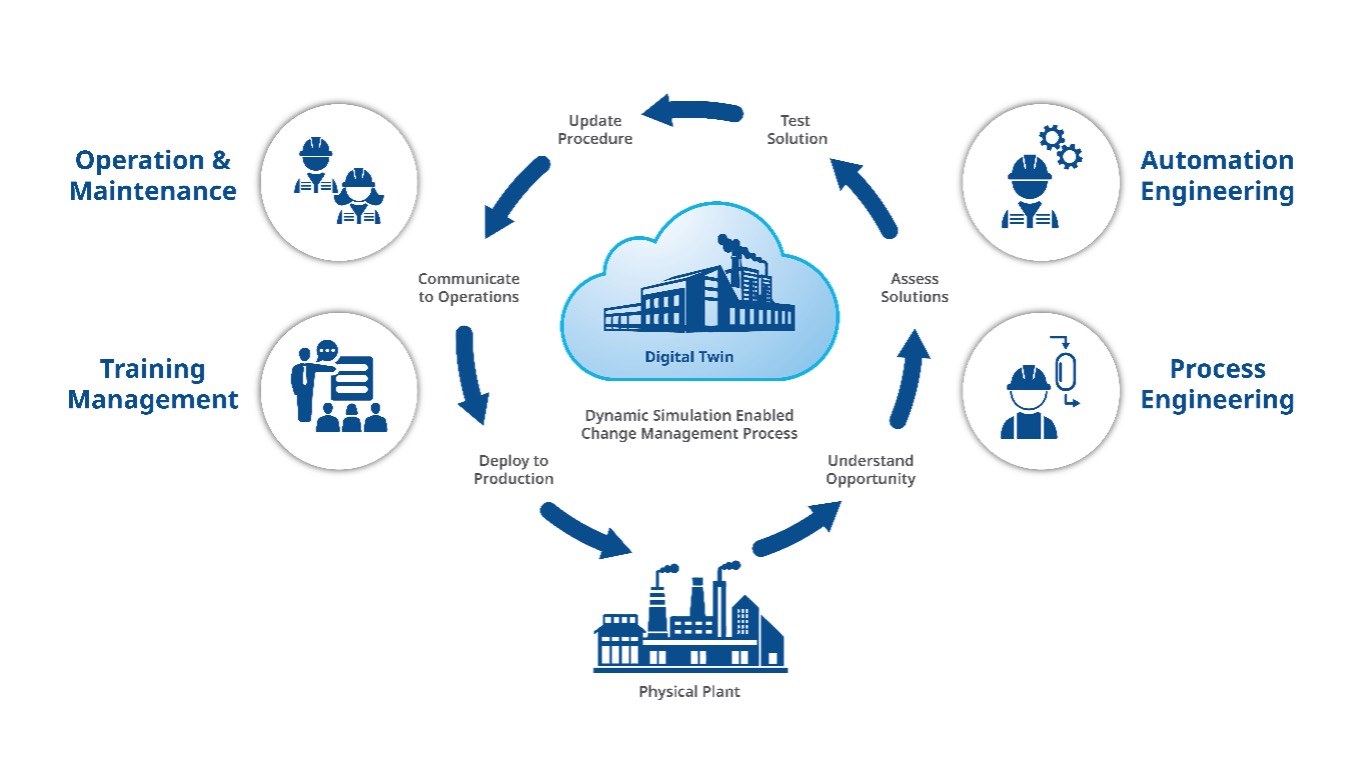

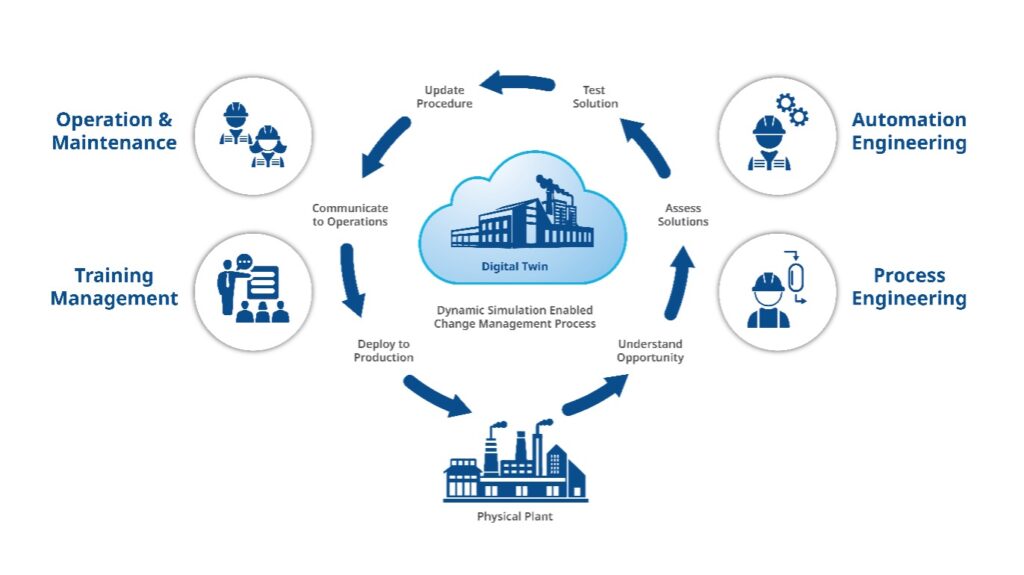

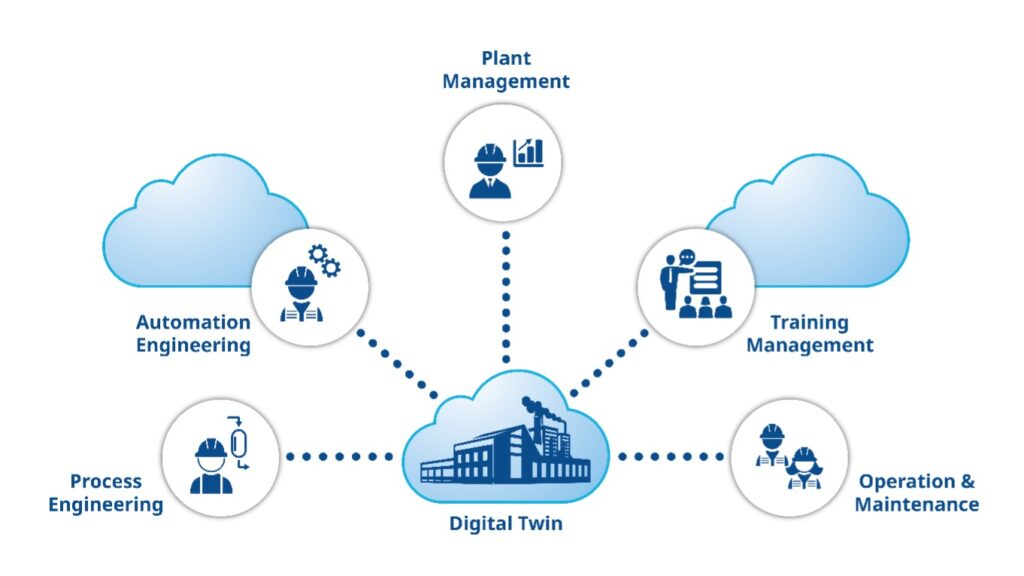

However, the value and ROI delivered in the project phase by simulation technologies is just the beginning. With the right planning and strategy, today’s organizations can move away from a project-centric model for deploying digital twin simulations, instead opting for a more holistic model that incorporates the digital twin into a full lifecycle change management workflow. The teams that do so quickly find that their digital twin not only pays for itself as part of the project, but it also delivers continuous value as a sandbox for collaboration among personnel in process and automation engineering, plant management, training management, operations and maintenance, and more (Figure 1).

Common digital twin simulation use cases

Today, digital twin simulation tools are often thought of as discrete assets designed to deliver project success through both automation testing and operator readiness. This understanding makes sense, as three of the core use cases of a digital twin deliver significant value and ROI during project execution.

1. Engineering design

In the earliest stages of project design, a digital twin simulation can help slash costs and schedule risk when teams use it to evaluate and validate their engineering and automation designs. In addition, teams can use their digital twins in tandem with capital cost estimation simulations to more easily scale project elements up and down to stay within budget.

2. Automation testing

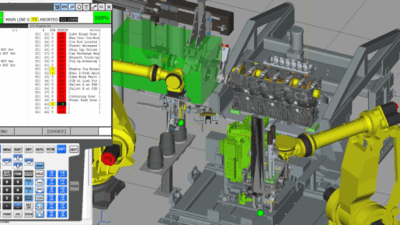

Teams also use digital twin simulation to test configurations, develop new process and automation strategies and fine tune operational strategies and results well before any equipment needs to be ordered, much less installed onsite. This type of offline startup and commissioning saves weeks to months of time on greenfield projects by having the automation system and operators run through startup procedures repeatedly until they are comfortable with the result, testing the automation in a wide variety of configurations — potentially hundreds of times — to determine the safest, most effective procedures.

3. Operator training

Immediately after project completion, a digital twin continues to deliver value. Operator training software used in parallel with the digital twin empowers operators with enhanced training. Users can experience new control strategies on systems that look, feel and respond exactly like the controls they will use in their day-to-day work, without any of the risk associated with practicing on live equipment. Because the digital twin is completed early in project development, the training solution can be built well before the project is finished, meaning operators can be trained and ready on the first day of operation.

Adding new value to digital twin simulation

Often, after project completion, the digital twin is shelved. However, an additional, more powerful use case exists for teams ready to make the most of their investment. Dynamic simulation tools also offer a versatile platform for operations teams to experiment with new equipment, strategies and configurations, enabling them to boost performance and promote sustainable practices — all without disrupting or jeopardizing plant operations — across their plant lifecycle. When equipped with the appropriate simulation software, these tools stay synchronized with the evolving plant environment, ensuring they remain a reliable resource for every functional area of the plant to enhance workflows and support teams in achieving their constantly shifting objectives.

Embracing digital twins as a digital sandbox

When teams embrace all the use cases of a digital twin simulation, they can unlock the benefits of a full lifecycle change management workflow solution. Successful changes are dependent on accurately designed solutions, proper configuration in implementation and successful adoption site wide, which requires clear communication and training. Whether it is deployment of a new graphics package, new platform, advanced process control, state-based control or even a change in how the process behaves, every adjustment impacts a complex existing workflow that touches many functional groups in the plant.

To ensure that impact does not cause disruption, teams must understand the areas of improvement from process and automation engineering perspectives, assess the best ways to make changes, test the solutions, update the procedures, notify operations of any changes, train operators on changes, deploy the solution to production and ensure the value of change is recognized through adoption by users. Each of those steps is important and interconnected, and a mistake in any one can result in a complex, costly, and time-consuming roll-back.

Digital twins empower teams to simulate the various aspects of a process and automation system to truly understand how everything will work together. The team simulates any issues so they understand them and can use their understanding to develop potential solutions. They test those potential solutions against the offline digital replica of the plant to gauge results and work out issues before implementing anything on the actual control system. Doing so simplifies change management and helps ensure smoother transitions for all stakeholders because every modification is examined from a much wider lens.

For example, an organization that recently experienced a safety event might need to remedy that event and prevent it in the future. But that job is often not the responsibility of a single group but rather many, including process and automation engineering, plant management, training management, operations and maintenance. If all those groups have access to a central sandbox for collaboration built on a digital twin, they can more easily work together to find a solution that most effectively solves the problem before implementing in production.

Employing digital twins for hazard, cost-benefit and other analyses

First, users can employ the digital twin to support process hazard analysis to identify what went wrong. Once everyone understands the root cause, they can come up with solutions. Automation and process engineering can determine if they need to automate or create new processes around operations or even change the process so that safety incident cannot happen again.

Further employing the digital twin, the team can perform cost-benefit analysis to identify which available solutions are optimal. They can also identify the safest, most accurate and most cost-effective ways to implement those solutions to explore deployment in the field, change operating procedures to reflect the new environment and train the operators effectively. Ultimately, because everyone is using the same comprehensive offline tool, that deployment is seamless when the team is ready to deploy a change to production (Figure 2).

However, it is not just safety incidents where a collaborative environment based on a digital twin is valuable. The solution can be applied to any change — from debottlenecking to control strategy changes and more — to continuously determine what manufacturers need, identify the solutions, train personnel, implement changes and then start the process over as many times as needed to identify and patch further gaps.

Owning digital twin solutions for success

Turning a digital twin simulation into a lifecycle change management workflow solution typically requires one key element that is often left out of project planning: ownership. If ownership of the digital twin solution by a long-term stakeholder is not established up front, it is often neglected and the simulation becomes increasingly irrelevant, making it a poor tool for change management.

In-house teams are typically entirely capable of managing a simulation across the lifecycle, but only if the team has a plan for who owns what and how often changes need to be synchronized to keep the digital twin current. Establishing this ownership upfront eliminates the extra costs necessary for a massive overhaul of the simulation if it drifts far out of sync with the production system. Ideally, identifying a long-term stakeholder and workflow for simulation management over its lifecycle will be part of the initial procurement of the digital twin.

Capturing the advantages of digital twins

As access to and use of digital twin simulations has become more common, teams around the globe are seeing dramatic benefits in the cost and schedule of their project execution. However, it is not a huge leap to extend the project benefits to lifecycle benefits from a digital twin, and the results will deliver significant value over the lifecycle of the system.

If organizations recognize the lifecycle potential of a digital twin, they can take steps early in project design and lifecycle planning to leverage the technology to create a collaborative sandbox. Doing so can help support the operational flexibility and organizational cohesiveness that drive competitive advantage — while simultaneously improving safety, production and sustainability across a plant or even a fleet.

Zachary Sample is an enterprise consultant with Emerson. Edited by Sheri Kasprzak, managing editor, automation & controls, WTWH Media, [email protected].