How to improve process control safety and risk management? Hazard and operability studies need to integrate sensor data, digital models and safety criteria to optimize plant health. See five components of interactive hazard and operability assessments.

Interactive hazard and operability assessment insights

- Learn why a digital, interactive hazard and operability assessment is needed for process risks.

- Examine three key benefits of interactive hazard and operability assessment (iaHAZOP) software and five core components.

- Examples show why run-time risk assessment matters, as it adapts to make safety part of daily operations.

Safety and risk management have never been static tasks. In a world of constant change — whether due to evolving technologies or fluctuations in experienced staff — managing operational risk demands more than periodic inspections and siloed documentation. The TÜV SÜD interactive Hazard and Operability (iaHAZOP) digital approach transfers critical safety data and expert knowledge into one dynamic software, enabling companies to stay ahead of disruptions while maintaining safe and compliant operations. See examples, below.

Why a digital, interactive hazard and operability assessment is needed

As production environments evolve, so must the methods used to oversee them. Regulatory requirements stipulate that each facility must have a risk assessment tailored to its current configuration. But many businesses still rely on static documentation, often in paper files or digital silos that can be difficult to locate or interpret, especially during off-hours or amid an incident.

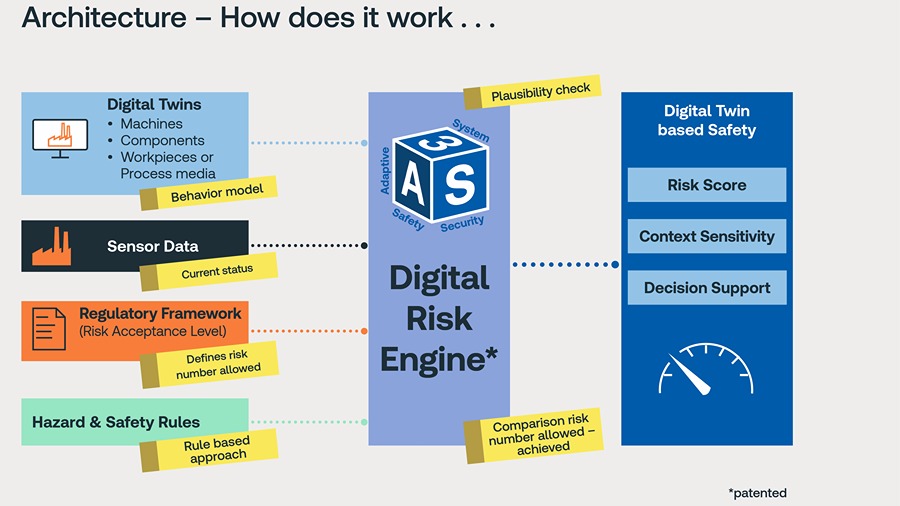

iaHAZOP goes beyond simple digital spreadsheets of conventional HAZOP studies. It transforms risk management into an integrated, run-time process that adapts to changing conditions. This solution continuously integrates sensor data, digital models and formal safety criteria to provide a comprehensive view of plant health.

Three key benefits of interactive hazard and operability assessments

During design or during active operation, iaHAZOP:

1. Offers immediate insights into potential hazards helping teams act before issues escalate. By aligning live process data with predefined safety thresholds and rules, the software generates up-to-date evaluations that reflect the actual state of the facility.

2. Supports fast, informed decision-making and facilitates compliance by automating parts of the documentation process.

3. Intentionally leaves key decisions and approvals with qualified personnel, ensuring that human expertise remains central to operational safety.

Behind iaHAZOP: Five core components

Five core components make interactive hazard and operability assessments a robust and future-oriented tool:

1. Digital twins replicate how equipment and systems behave, thus making it possible to anticipate problems before they occur. These models can be hosted on-site or in the cloud, depending on a company’s infrastructure.

2. Knowledge graphs structure connections between different elements of the facility, drawing from historical studies, incident records and engineering experience to create a web of meaningful relationships.

3. Real-time sensor inputs offer continuous updates from process parameters like pressure, temperature or flow. This enables quick detection of abnormal conditions.

4. Hazard rules translate physical and chemical safety principles into programmed logic, allowing consistent risk identification even when systems are modified or reconfigured.

5. Regulatory benchmarks are embedded into the tool, ensuring that evolving plant conditions are constantly evaluated against accepted standards.

Together, these methods allow the software to maintain a holistic view of safety, not as a snapshot picture, but as a continuously evolving movie.

Examples why run-time risk assessment matters

Several real-world cases illustrate the impact of a more dynamic approach to safety. In one incident, a valve was thought to be sealed off but was actually leaking due to erosion. This fact was overlooked because the operator did not have this knowledge available, although the engineering and maintenance department was aware of it, which led to an explosion. In another case, pressure remained undetected in the system. This led to injuries of the maintenance staff during boiler work. The software, with its combination of historical maintenance data, live sensor readings and digital twin simulations, could have flagged these risks in advance.

Even subtle operational changes, like modifications of the process that are not accompanied by an update of the risk review, can have significant consequences. The software tracks these adjustments during run-time and updates the risk status accordingly, reducing blind spots that could otherwise go unnoticed.

Interactive hazard and operability assessment software adapts

Whether managing a flexible modular plant with frequent product changes or overseeing a large, complex facility with compartmentalized teams, interactive hazard and operability assessment software supports safer operations by connecting information that is too often isolated. In modular setups, the software helps reassess risks dynamically as modules are swapped in or out. In larger installations, it bridges gaps between departments by merging data sources and aligning them under a shared safety framework.

Staff fluctuation adds to the complexity of the scenario. Experienced operators are retiring, taking with them much of the institutional knowledge that traditional risk management approaches were built on. The result: a growing mismatch between actual operational risks and available safety assessments.

Importantly, iaHAZOP can be rolled out in phases, making it accessible to companies at various stages of digital transformation. Businesses with extensive data infrastructures can integrate it quickly, while others can adopt it gradually to build a modern risk management approach over time.

Conclusion

The core value of interactive hazard and operability assessment software lies in its ability to make safety a living part of daily operations, not a periodic chore or an afterthought. By creating a network of continuously updated data, expert knowledge and predictive models, TÜV SÜD empowers companies to take control of their operational risks before they turn into problems. This is not just about avoiding downtime. It is about fostering a safer, smarter and more resilient way of working.

Michael Pfeifer is senior expert adaptive safety and Alexander Kurdas is expert for machinery and electrical safety, TÜV SÜD Industrie Service GmbH. Edited by Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected].

Learn more online

https://www.tuvsud.com/en/services/technical-advisory/hazop