System integration experts provide more on “How to select the right controller type for the automation application,” a Sept. 25 Control Engineering webcast, below answering more audience questions than webcast time allowed.

Automation controller experts provide more answers about “How to select the right controller type for the automation application,” after the Control Engineering Sept. 25 webcast that will be archived for a year. Audience listening live had the opportunity to submit questions to presenters.

Some answers include information on controller virtualization, programmable logic controller (PLC) scan time, controller interoperability, controller configuration, thin clients, artificial intelligence (AI) and controllers, PLC cybersecurity and controller education.

Webcast instructors to help with automation controller selection

The experts in the webcast and providing the extra answers were:

- Jon Breen, founder/owner, Breen Machine Automation Service LLC

- Vinoth Upendra Janardhahan (“Vinoth”), automation engineer, CDM Smith.

The learning objectives for the webcast were:

- General trends in industrial controller types, forms and functions.

- What industrial controllers you have and what industrial controllers you need based on technologies and applications.

- Examples of how industrial controllers are applied in various automation applications and why, with anticipated or actual benefits.

Controller interoperability, scan time, education

Additional answers on controller interoperability, scan time, education, cybersecurity and other automation controller selection topics follow.

Why does PLC scan time need to be 10x faster than the process? If the process can’t change that fast, then there’s no change for the PLC to make yet.

Vinoth: In general, a 10X faster scan time ensures stability and helps a controller to respond to changes. If it scans as fast as the process changes, it may miss capturing some important process variations. By scanning faster, it can update outputs before the process changes or shifts. As an example: If the process reacts in ~100 ms, a 10 ms PLC scan keeps control smooth and safe.

Is virtualization a viable option to Microsoft Windows for control software?

Breen: I’d welcome more open-source options, but don’t expect them soon. Regarding virtualization, yes, I’ve been using virtual machines (VMs) for about 15 years to manage old controls software. Most of that has been with VMWare [by Broadcom] (my YouTube playlist explains how to use VMWare), but VMWare has been going through some changes that make it less suitable for our use, so we’ve recently transitioned to Hyper-V (built into Microsoft Windows). I’ve also seen Oracle VirtualBox used, and people seem happy with it. I would recommend VMs for anyone managing old systems or many vendors.

Vinoth: Historically Microsoft Windows has dominated the control software because it was prevalent everywhere, providing better networking and driver supports. Even today, most control platforms are tested, certified and supported only on Windows, predominantly in the mainstream supervisory control and data acquisition (SCADA), distributed control system (DCS) and controller architecture.

But Linux-based systems [Linux Foundation] are slowly being added (especially can be found in the edge-devices), but it may take many more years before it becomes a standard in the mainstream industrial control system as it needs to pass all the validation and certification requirements.

Yes, virtualization can be a good option for old/legacy systems. This can help plants maintain old control applications securely while running on modern server hardware.

How do you think Open Process Automation [The Open Group] could change the market?

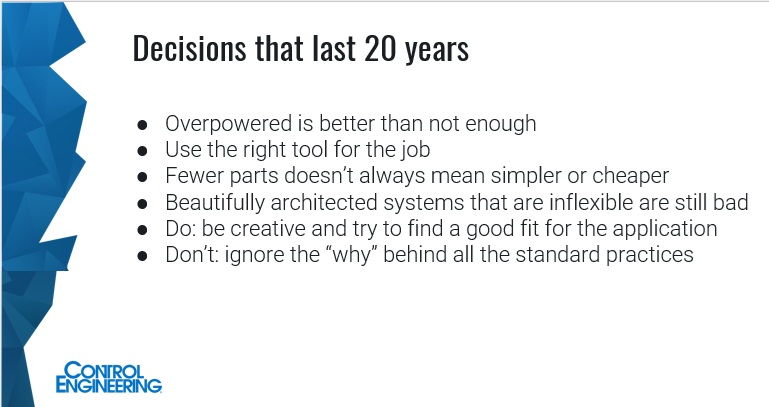

Breen: As I mentioned in my presentation, vendor lock-in is a real challenge. End users are stuck between needing parts to work together (standardize on a vendor) and the monopoly that creates (vendor can charge whatever they want). This is further exacerbated by the generally closed nature of industrial automation information. You can’t go to Amazon and get a thousand reviews on a given PLC or brand. Controller comparisons are rarely apples to apples, and the information available across forums and publications is scattered and scant. The Open Process Automation vision is a controls ecosystem where components are interoperable and interchangeable. That would completely change the game. Comparisons could be apples to apples; end users wouldn’t be forced to buy everything from one vendor, and PLC manufacturers would have to compete on price and performance. This would be a very good thing for end users. The trouble is, all the big PLC manufacturers like their little monopolies, and will push back hard against this type of standard. I don’t think it has enough industry backing to make a broad impact yet, but I hope to see that change. Based on history, I’d guess it will take one or two enormous companies to drive it forward. Then the rest of us may be able to benefit from it.

[Control Engineering explains more in the article: New insights: 100-controller ExxonMobil Open Process Automation. ]What was the first PLC manufacturer?

Vinoth: Modicon (now part of Schneider Electric) in 1969 made the Modicon 084. “PLC” originally came from “Programmable Logic Controllers,” a term coined by Modicon.

[ Control Engineering has more PLC history at:https://www.controleng.com/dick-morley-remembered-as-father-of-the-plc/ ]

Can you offer a configuration spreadsheet to work with automation contractors?

Vinoth: Configuration spreadsheets can be generally useful to align contractors and end users by clearly documenting controller type, input/output (I/O) counts, communication protocols, redundancy needs and integration requirements. There are lot of ways and formats it can be done. You could also try ISA-95 style templates.

As an example, you could build a spreadsheet with the following:

I/O configuration – Lists all PLC/field devices, signal types, ranges, addresses, and other notes.

Variable frequency drive (VFD)/drive configuration – Motor ratings, control modes, accel/decel times, and communication setup.

PLC hardware – CPU models, rack/slot layout, total IO, and communication modules.

HMI/SCADA Configuration – Graphic screen names, tags used, alarms and communication links.

Alarm and safety – Alarm tags, priority/severity, delay times, and acknowledgement requirements.

Instrumentation specifications – Instrument type, range, accuracy, manufacturer and location.

Is “thin client” still a hot item and how does it fit into the inventory of definitions?

Vinoth: Yes, thin clients are still relevant. A thin client is part of the HMI (human machine interface) layer, providing lightweight, secure access to the centralized SCADA system. No control logic or graphics reside in a thin client, hence they simplify deployment and improve cybersecurity requirements. For example: With virtualization, server-based HMIs and remote monitoring requirements, thin clients are emerging as preferred front-end devices.

Are there a lot of customers running pilots adding PLCs and analyzing the data with AI to assist with predictive maintenance?

Vinoth: Yes, trends are taking that route. You can stream PLC/SCADA data into a cloud or an edge device to perform all sorts of analytics. The ideal approach would be to start small with pilot projects on a critical asset, validate accuracy and then scale up. For example: an edge device can be used to collect vibration data from pumps, analyze it locally and only send alerts or summaries back. This avoids overloading PLCs and provides real-world early warning of failures.

What is current situation with cybersecurity and attacks on PLC systems?

Vinoth: I believe Stuxnet was around 2010 when a worm was used to target an Iranian centrifuge system. After that, we are migrating towards cybersecurity related to zero-trust, defense-in-depth protocols, OT-IT network segmentation, encrypted communication protocols, role-based access, and vendors issuing frequent patches for vulnerabilities. Standards such as ISA/IEC 62443 and related certifications are being widely referenced and promoted.

Even with all these, industrial and OT environments still lag in basic security habits with use of legacy systems, hard-coded passwords and poorly designed network architecture. But we are seeing more PLC vendors shifting toward built-in security with encryption, secure protocols and better firmware management.

[Read more on Stuxnet from Control Engineering: https://www.controleng.com/throwback-attack-how-stuxnet-changed-cybersecurity/ ]We don’t need expensive industrial automation equipment, just something for students to learn.

Breen: Getting a foot in the door for industrial controls is harder than it should be. I’m a strong advocate for education in industrial automation. I’ve taught controls at university and tech school, and I continue to produce content to help those learning industrial automation. The first thing I want to note is that a physical control system isn’t required for most of the concepts a student needs to learn. A platform that supports simulation will get you most of the way there. I discuss the considerations in my article “Free PLC Programming Software for Education.” I have been building a free library of instructional videos that focus on universal concepts. Learn more about our services and training at www.Breen-Machine.com. I hope this helps!

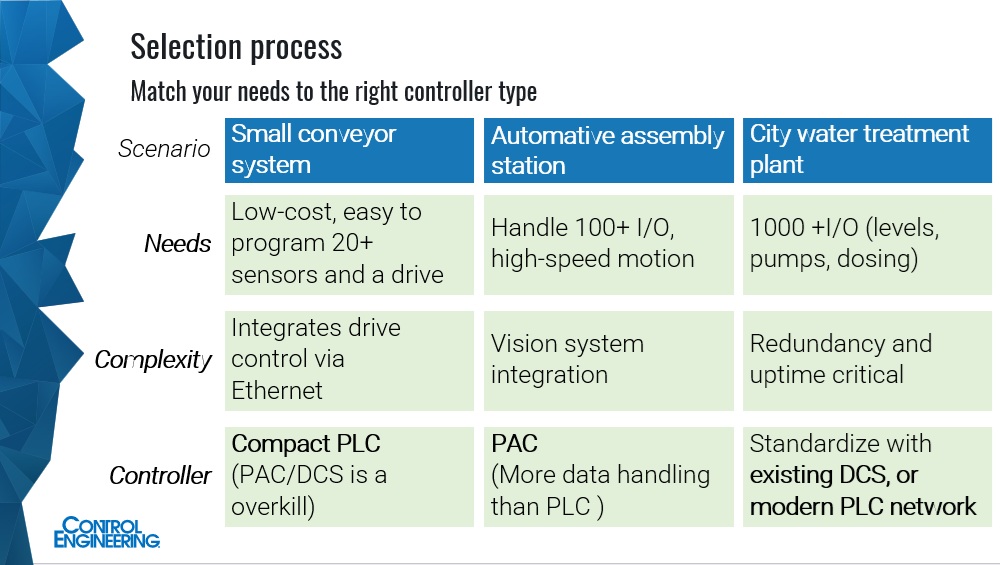

Is controller selection an art of engineering, or is there a flowchart to help with selection?

Vinoth: In my opinion, it should be both. We need requirement-driven checklists or flowcharts discussed in the webcast such as inventorying what you have then defining I/O counts, performance needs, environment, redundancy, lifecycle, etc. But trade-offs exist, such as cost versus redundancy or PAC versus DCS in mid-sized plants. It’s not guesswork, but it’s not purely mechanical either. Think of controller selection as structured analysis guided by engineering experience. Learn more at https://www.cdmsmith.com/.

Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media and Technology, [email protected].

Keywords

Industrial automation controllers selection, PLC selection

Consider this

How are you improving your use of automation controllers?

You also might like