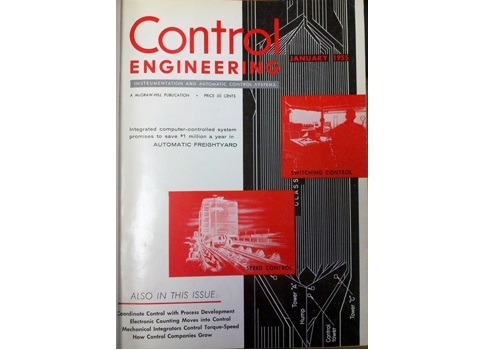

American railroads pay $100,000,000 a year for freight damaged—much of it in yards where trains are assembled. This new computer-controlled system promises to slash the bill. It controls the rolling speed of cars so that they couple gently.

Happy 60th, Control Engineering! Our magazine first published in September 1954. This monthly column in 2014 will resurrect some of our favorite material from the 1954 and 1955 issues. Technologies have progressed, but they continue to pave the way for today’s innovations.

A 100-car freight, eastbound from Portland, Ore., waits on a track in the Union Pacific’s yard at North Platte, Neb. Beside it stands a similar train from Los Angeles. Both have cars destined for Chicago, Kansas City, Atlanta, and New York.

Here at the center of the United States the trains will be reclassified. They will be dismembered, and the cars will be collated into new trains with destinations more specific than just "east." On a long journey a freight car may pass through several such classification yards. If its route is coast-to-coast, it may start on any train headed in the right general direction. But as it approaches its destination, it must be aimed more exactly.

In most classification yards, switch engines shuffle the cars. But the big ones, such as the Union Pacific’s North Platte yard, depend on "humping." A train that is being reclassified is backed slowly over a rise, called in railroad parlance the "hump." Just before a car hits the downgrade, a switchman pulls the coupling pin. Then the car, cut loose from the train, rolls freely to one of the tracks that fan out from the hump. Each of these tracks is the storage for a new train. Ideally, a hump yard slopes so that each car coasts down at a constant velocity. Unfortunately, cars differ. Some will accelerate so that they reach the final track at high speed and couple with a resounding crash, smashing or shifting their loads. Others decelerate and stall midway, so that a switch engine has to pursue them and nudge them along. A strong tailwind, for example, will give wings to even the most sluggish car.

So that the switchmen can exercise some control over the velocity of a car leaving the hump, many classification yards have installed "retarders," steel brakes along the rails that grip the flanges of the wheels. A switchman perched in a control tower operates the retarders remotely. According to his judgment, he must apply just the right amount of braking pressure so that each car will arrive at the end of the track rolling about 2 mph.

This requires inhumanly precise judgment. Even an experienced switchman struggles with maintaining the yard. Specific friction characteristics vary across cars, and wind velocity isn’t always consistent. But several years ago, Ronald Berti, an assistant electrical engineer at Union Pacific; signal engineer David C. Bettison; and John Eckenbach, a project engineer at Reeves Instrument Corp., started developing an automatic retarder yard. They developed a computing control system that measures the rolling characteristics of each car, calculates the correct exit speed from the retarder, and then controls the retarder. Although the Union Pacific expected no miracles, eight of its 42 tracks now incorporate the new system. After two months of trial operation, the system operates successfully and has reduced freight damage by 80%-an annual savings of $800,000 for the North Platte Yard. To equip the rest of the yard, Union Pacific estimates a price tag of only $250,000.