A new 3D ultrasonic sensor empowers developers to achieve 360-degree obstacle detection around mobile robots at a fraction of the cost of the robot sensor packages typically used today. How does it work? What does it mean for autonomous robot designers? What is ADAR?

Acoustic detection and ranging (ADAR) sensing insights

- Learn how ADAR uses beamforming and miniaturized ultrasonic transducers to achieve 3D object detection in air, offering a novel approach that differs from traditional methods like LiDAR.

- Understand the limitations of 2D LiDAR systems, including their narrow field of view and challenges with transparent or reflective surfaces, and how ADAR provides a more comprehensive and cost-effective solution for obstacle detection, especially in the context of mobile robots.

- Know that ADAR can be integrated with other sensors like cameras for enhanced capabilities and that its applications extend beyond mobile robots to include industrial and humanoid robots.

Ole Marius Rindal, Ph.D., Sonair

Acoustic detection and ranging (ADAR) sensing technology uses beamforming with miniaturized ultrasonic transducers to provide 3D object detection, offering a cost-effective and comprehensive alternative to traditional 2D light-detection and ranging (LiDAR) systems for applications like mobile robots.

Two special moments during the development of an innovative 3D ultrasonic sensor brought home the ground-breaking potential of related sensor research. The first came when Frode Tyholdt, co-founder of Sonair, managed to produce high quality miniaturized (<2mm from the current ~15mm) ultrasonic transducers building on decades of research from the SINTEF research institute. (We were both working at SINTEF at the time and through an innovation project found a way to arrange the transducers in the arrays required for beamforming.)

Beamforming is the principle that underlies other ultrasound technologies from 3D medical ultrasound imaging to SONAR (sound navigation and ranging) and has been around for decades. Beamforming allows sensors to transmit and receive sound from different directions.

But beamforming in air requires transducers that are small enough to be spaced half a wavelength (λ/2) apart. Miniaturization was key to unlocking the new technology, which enables beamforming in the medium of air (as opposed to body tissue or water) for the first time in a commercial product.

Applying algorithms used in medical ultrasound imaging to a sensor confirmed that the new technology could readily perform depth sensing and obstacle detection.

By tweaking algorithms and exploiting the understanding of air as a medium lead to the feasibility of ADAR-based measurements with a new category of sensors that enables 3D ultrasound object detection in air. Ultrasound in air sensors already exist, but the most well-known, the parking sensors on automobiles, are one dimensional, which means they sense in just one direction and only provide distance information. ADAR provides x, y, z coordinates necessary to create a 3D view.

ADAR, new technology, similar to established technologies

ADAR is a newcomer but can be thought of alongside established technologies such as radar (radio detection and ranging) and SONAR. The key difference is that ADAR works acoustically in the air, sonar works underwater and radar uses radio frequencies. ADAR takes well-established beamforming principles and applies them to air.

Tiny, powerful ADAR sensors have progressed over the past few years through successful pilots and award ceremonies. After full commercial release set for later this year, ADAR sensors will be available for integration and use in mobile robot designs.

Ensuring safe human-robot coexistence

Humans and autonomous mobile robots (AMRs) are increasingly sharing the same spaces, from city streets and factory floors to hospitals, warehouses and even in residential applications. AMRs are seeing increased adoption worldwide due to their effectiveness across multiple material handling applications and spurred by labor shortages across the manufacturing, logistics and warehouse sectors. In fact, the global mobile robot market grew 27% in 2023 to reach $4.5B, according to analyst firm Interact Analysis.

Ensuring safety for humans in these shared spaces is key to supporting automation adoption across multiple environments. Obstacle detection is, of course, a key element of any mobile robot’s safety system.

Sensors, AMRs: How to reduce mobile robot cost

What is the most expensive part of an AMR? The chassis? No. The motor? No. The rugged outer shell? No. Surprisingly, it’s the sensor package. Today’s AMRs employ various combinations of sensing and camera technologies, including 2D safety certified LiDAR, to help robots navigate their environment while safely detecting obstacles. The sensor package in a typical AMR can account for 30% or more of the total hardware cost.

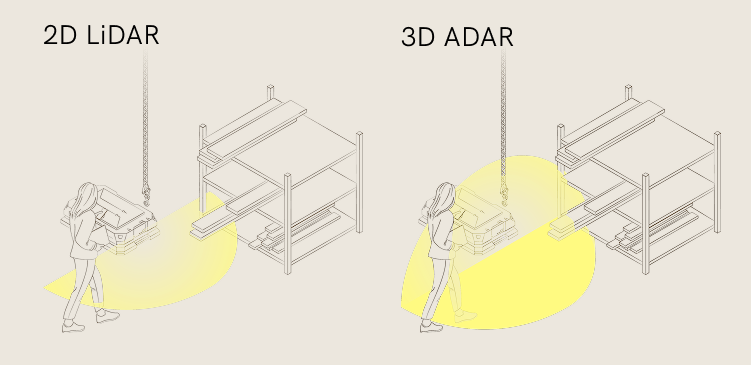

LiDAR has known limitations when it comes to effective obstacle detection. Most importantly, 2D LiDARs have limited field of view (FOV) and can only sense a small, two-dimensional slice of the environment around a robot. This means that LiDAR cannot detect objects outside the 2D plane.

LiDAR’s detection issues

2D safety LiDAR are typically mounted on AMRs at a height of around 20cm (7.9 inches). If there’s an object 10 cm above the floor, LiDAR won’t detect it. If there’s an object that’s hanging from the roof, LiDAR won’t detect it. If there are items sticking out from walls or shelves, 2D LiDAR won’t detect them.

LiDAR has issues beyond its limited FOV and 2D sensing. Different lighting conditions in the warehouse can create challenges for LiDAR. Moreover, LiDAR cannot detect transparent and reflective surfaces, which presents safety risks.

In contrast, the new 3D ultrasonic sensor provides a 360-degree (180 x 180) view of the scene up to 5m distance (16.4 feet). In effect, the new sensor can be used to create a 3D safety shield for obstacle detection around any AMR. That’s a major safety enhancement – but perhaps the most remarkable aspect of the new technology from a robot designer’s perspective are the cost savings involved.

50% to 80% cost savings while boosting safety

2D safety certified LiDAR sensor package typically costs about $4000, whereas the new 3D ultrasound sensor will cost approximately one-quarter of that when released later this year.

With AMRs typically carrying two 2D safety LiDAR, removing these expensive sensors produces an immediate $8000 saving. Deploying four ADAR-based sensors instead, at an approximate cost of $4000, provides the AMR with 360-degree protection from obstacles and at 50% lower cost compared to 2D LiDAR-based alternatives.

2D safety LiDAR are used to support autonomous navigation capabilities. To retain those capabilities, robot designers could use the new sensor with much cheaper, non-safety rated LiDAR, which costs around $500, while the new sensor performs the improved 3D safe obstacle detection function. Depending on the configuration, the new technology reduces the cost of the safety sensor package by between 50% and 80%, while boosting safety.

ADAR costs less, produces actionable data for robotic, other applications

AMR designers are used to handling LiDAR-generated point clouds that produce millions of data points. This requires a lot of processing power and speed and it has also created a sense that more is better when it comes to data points. The new technology demonstrates that this expectation is not necessarily correct.

The new 3D ultrasound sensor produces fewer data points than LiDAR and 3D camera systems, but crucially, the points it produces are actionable. Instead of providing millions of data points that require a lot of postprocessing, the new sensor provides the key data points for AMR to detect obstacles.

Confronting preconceived notions

Before participating in the technology’s successful and ongoing, early ADAR sensor access program, some people expressed skepticism about the concept of using ultrasonic sensors for obstacle detection. However, in most of those cases, they had tested older ultrasonic sensors that did not meet their expectations. Testing the new technology revealed the powerful capabilities of the ADAR-based 3D ultrasonic sensor. It enhance robots’ safety view from 2D to 3D and less cost than most sensor packages.

Future is sensor fusion in mobile robot systems

None of that means that the new 3D ultrasonic sensor will replace all the other sensors used in robots today.

The best performing mobile robot systems tend to use a combination of complementary sensors rather than relying on just one. The future is not for one sensor to rule them all, but an integration and fusion of sensor technologies, providing sensor redundancy.

Combining the new 3D ultrasound sensor with cameras, for example, enables low-cost visual simultaneous localization and mapping (vSLAM) navigation, boosting the sensor’s value and usefulness.

More sensor system integration and sensor fusion are expected in the future, with the new ADAR-based sensors being a powerful addition to any robot’s sensor suite.

ADAR for industrial robot arms

The new sensor is a great fit for mobile robots, especially with the rapid robot adoption in that domain and the need to ensure safe human-robot coexistence, but ADAR use cases extend beyond AMRs. Any robot that would benefit from 3D obstacle detection is a good candidate for this innovative sensor.

For example, it could be integrated into a standard industrial robot arm and used to detect when a human enters the workspace, immediately sending a signal to bring the machine to a halt. Similarly, humanoid robots could use the sensor to ensure there are no collisions with humans or property in domestic settings.

Ole Marius Rindal, Ph.D., is co-founder and technology manager, Sonair. Edited by Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected].

CONSIDER THIS

- Does your mobile robot have blind spots?

ONLINE