Most refineries, more than 40 years old: How to improve

RELATED PRODUCTS

PRODUCT INFORMATION

MANUFACTURED BY Mark T. Hoske

PUBLISH DATE

June 6, 2025

RELEASE DATE

June 6, 2025

CATEGORY

Digital Transformation

Refinery operations insights

- Because 60% of U.S. refineries are more than 40 years old, those and newer facilities benefit from software tools and services to better manage, optimize, operate and secure those assets according to L&T Technology Services at ARC Industry Leadership Forum 2025.

- Refinery software and services can improve operational goals for refineries.

- Quantified benefits for refinery assets, safety and productivity can include 12-15% equipment downtime reduction, decrease safety incidents approximately 30-40% and digital twin for plant operations can improve yield and efficiency 5-10%

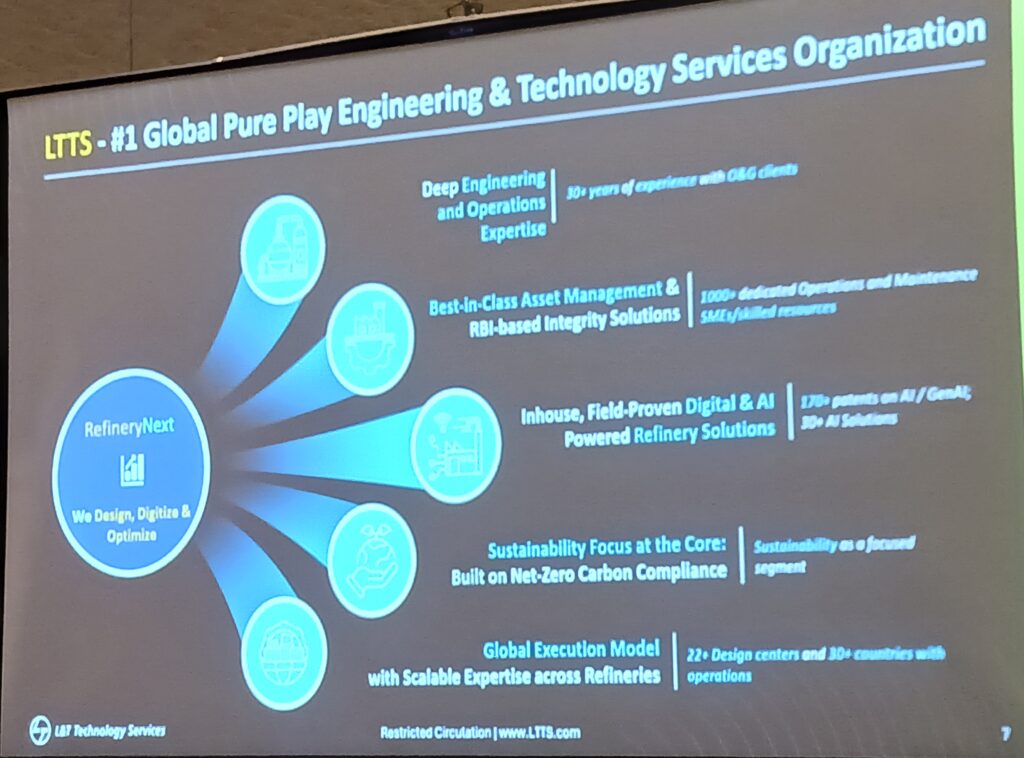

Because 60% of refineries are more than 40 years old, automation and other assets and operations need help, explained Subrat Tripathy, chief segment officer-process industry, L&T Technology Services (LTTS) at the ARC Industry Leadership Forum 2025. During an ARC Advisory Group news conference, Tripathy discussed how to enable the refinery of the future with purposeful, agile engineering. Existing refineries face multiple challenges related to reliability and efficiency, safety, energy consumption and regulatory compliance. For example, the digital twin for plant operations can improve yield and efficiency 5-10%, reduce safety incidents 8-10% and reduce the defect rate 10-12%.

Process industry, refining challenges quantified

Four concerns for U.S. refineries are:

- Reliability and efficiency: Average age of a U.S. refinery is over 40 years, and unexpected down time costs more than $50 billion annually.

- Safety: Lost time injury frequency has risen by 60% over the past 5 years.

- Energy consumption: Higher energy consumption per unit of output. Increase in production costs by 15-20%. Regulatory compliance: 10-15% increase in cost of non-compliance year over year and a need to reduce emissions by 30-40% until 2030.

Refinery software and services improve operational goals

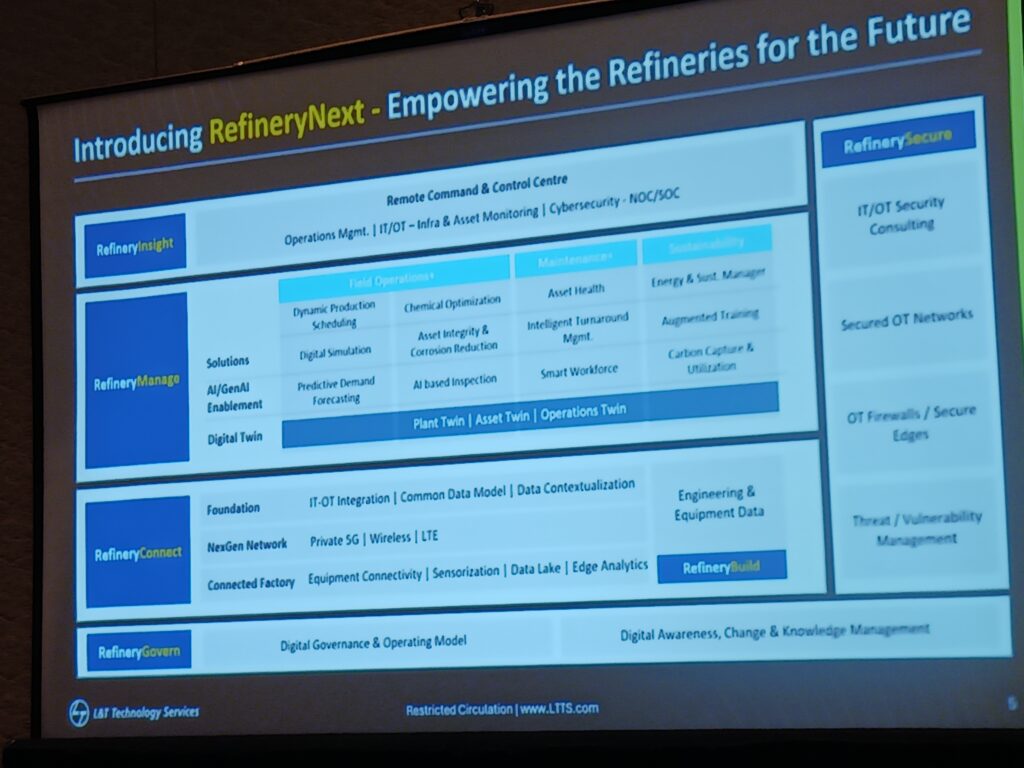

Advanced software and services can be integrated with existing refineries for designed into new, smart refineries. LTTS RefineryNext offers integration of information technology and operational technology (IT/OT), digital governance frameworks and artificial intelligence (AI) tools for predictive maintenance, intelligent asset solutions and demand forecasting. It includes digital twins and carbon capture capabilities for sustainability practices such as energy optimization and net-zero carbon compliance. Areas within RefineryNext include:

RefineryGovern and enhanced cybersecurity to safeguard operations.

- RefineryConnect provides real-time insights with legacy equipment. The foundation includes IT-OT integration, common data model and data contextualization. Next-generation wireless networking can integrate private 5G wireless and 4G LTE. Connected factory capabilities improves equipment connectivity, sensorization, data lake and edge analytics.

- RefineryBuild works with engineering and equipment data to create a connected factory

- RefineryManage to improve field operations, maintenance and sustainability. Tools include digital simulation, asset integrity and corrosion reduction, intelligent turnaround management augmented training. AI and generative AI enablement helps with predictive demand forecasting, AI-based inspection, smart workforce tools and carbon capture and utilization. Digital twins include a plant twin, asset twin and operations twin.

- RefineryInsight remote command and control center providing operations management, IT/OT infrastructure and asset monitoring and cybersecurity.

- RefinerySecure for IT/OT security consulting, secured OT networks, OT firewalls and secure edges and threat vulnerability management.

The modules can be applied separately or together as needed. Refineries that adopt RefineryNext can achieve a “marked reduction in safety incidents, minimized equipment downtime and a significant increase in productivity,” the company said, along with “substantially lower maintenance costs, ensuring superior operational efficiency and profitability.”

Quantified benefits for refinery assets, safety, productivity

Realtime asset health monitoring benefits include a 12-15% equipment downtime reduction, 5-8% maintenance cost reduction and approximately 5% increase in equipment productivity.

Digital rollout for environmental, health, safety and security (EHSS) can decrease safety incidents approximately 30-40%, increase asset utilization and productivity approximately 10% and ensure 100% incident reporting and compliance.

The digital twin for plant operations can improve yield and efficiency 5-10%, reduce safety incidents 8-10% and reduce the defect rate 10-12%. Digital twin for assets can reduce noncompliance risk 10-15%, reduce time on information searches 30-35%, and increase workforce productivity by 15-18%.

Other benefits include agnostic solutions that integrate with existing automation and tools from different vendors.

Tripathy said the tools combine new technologies with LTTS expertise in plant engineering and digitalization to “Strengthen our engagements in the oil and gas sector for a future that prioritizes safety, efficiency and environmental responsibility.”

L&T Technology Services Limited (LTTS) has more information about oil and gas industry sustainability at https://www.ltts.com/brochure/oil-and-gas.

Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected].

CONSIDER THIS

Is your refinery starving for improvements?

ONLINE

https://www.controleng.com/digital-transformation

Search “ARC Industry Leadership Forum 2025” for other coverage from the event.