The University of Michigan and Arizona State University are seeking industry partners for a potential NSF research center.

To address challenges limiting the effectiveness of digital twins in manufacturing, the University of Michigan (U-M) and Arizona State University (ASU) are inviting industrial partners to join a new Center for Digital Twins in Manufacturing.

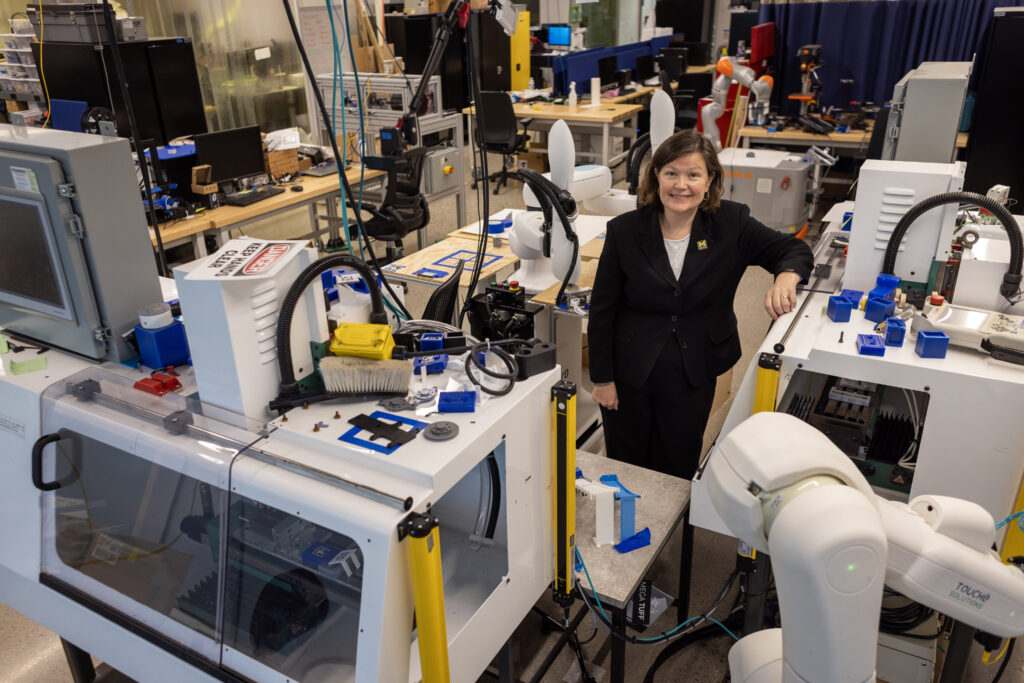

“Everyone’s building digital twins, but we’re trying to build the glue or connectivity that enables digital twins to work together—to be composable, reusable and maintainable,” said Dawn Tilbury, the Ronald D. and Regina C. McNeil department chair of robotics at U-M. “Teams in this center will work on precompetitive issues that can bring broad benefits to everyone making and using digital twins, helping expand the use of these great technologies to improve manufacturing performance, quality and uptime.”

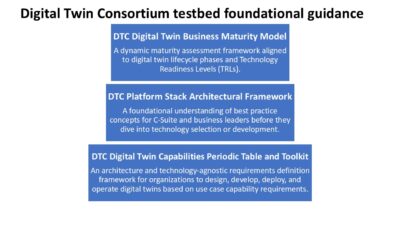

Tilbury is also the Herrick Professor of Engineering and a professor of mechanical engineering and electrical engineering and computer science. Pending sufficient industry support, the team plans to establish an Industry-University Cooperative Research Center supported by the National Science Foundation. These centers operate within existing university laboratories. NSF provides $1.5 million over five years to cover administrative costs, while industry partners contribute annual dues of $90,000 to support research efforts.

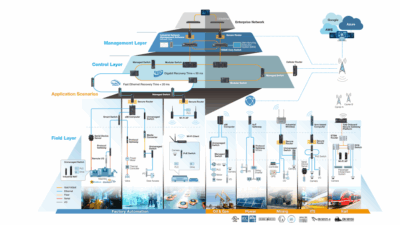

A digital twin is a virtual model that synchronizes with a physical device by receiving real-time data. For example, a digital twin of a milling machine may monitor machining progress in near real time, updating at regular intervals to reflect the physical system. It can estimate part quality, predict maintenance needs, and support process improvements. However, implementation in manufacturing remains challenging due to a lack of standardization.

Currently, most digital twin implementations in manufacturing are focused on individual devices. In cases where a digital twin represents an entire production line, the software is typically custom-built and may require substantial modification if system components are updated. Many vendors offer digital twin solutions for specifics machines., but integrating these with models of adjacent equipment could enhance coordination across the production process.

The proposed center aims to address challenges in applying digital twins in manufacturing through multiple approaches. One focus is on developing adaptable digital twin models for specific machine types, such as 3D printers, which can be configured to reflect particular equipment. These models are intended to support ongoing use and updates, accommodating system modifications, machine wear and changes resulting from maintenance or part replacements.

Other aims of the center include:

- Measuring and reducing variability in digital twin models

- Improving model accuracy to support more reliable decision-making in factory operations.

- Creating task-specific digital models for human-robot interaction

- Modeling only the relevant aspects of human actions to improve coordination with robots while addressing privacy considerations. Applying digital twin software for simulation and scenario analysis

- Enabling factory personnel to test potential equipment changes, factory line configurations, and conduct training in a virtual environment.

- Autotwin: Software that can generate and run digital twins

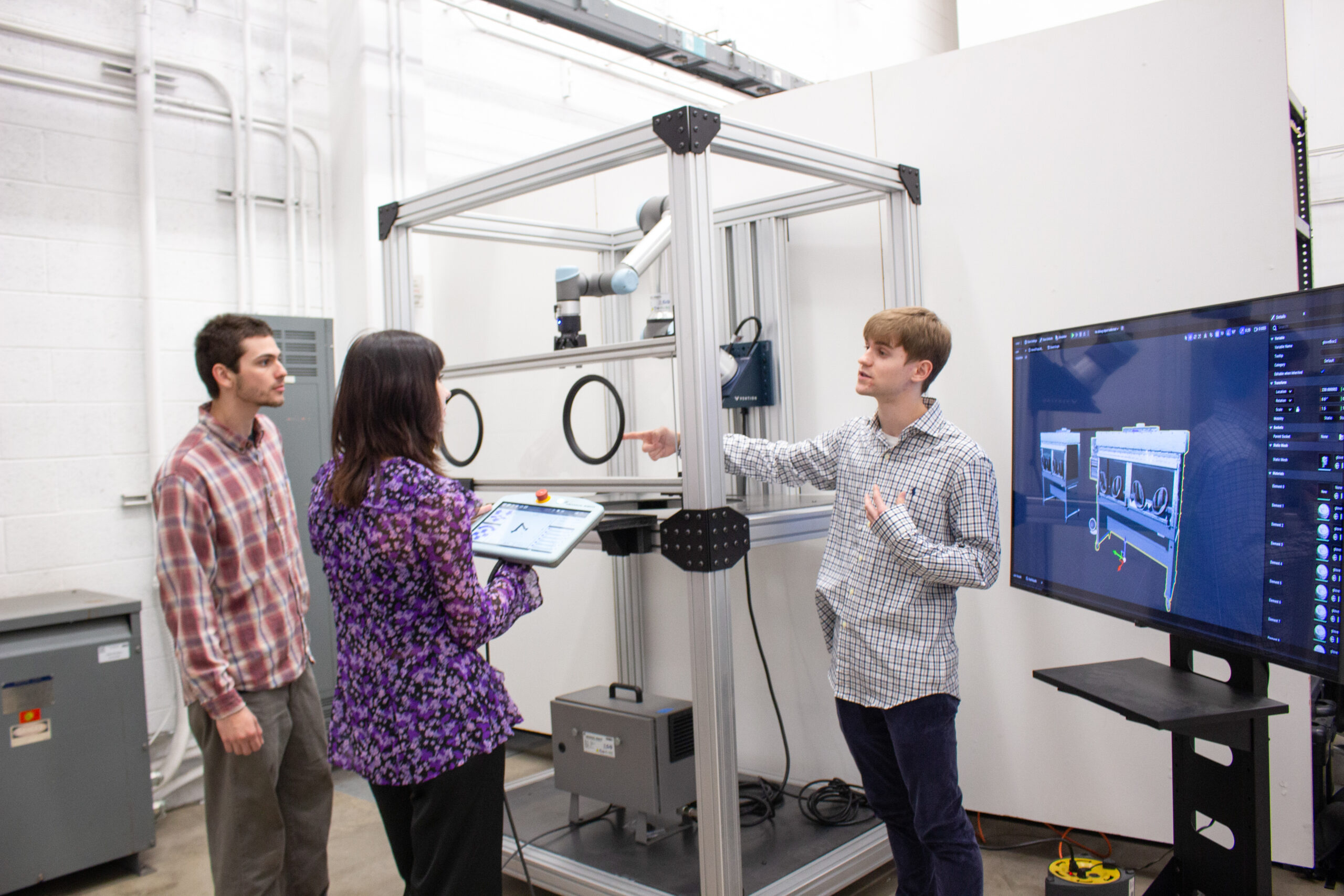

To evaluate proposed methods developed by the center and verify their functionality, U-M provides a test environment called SMART 4.0, which include mobile robots, computer-controlled machines, and 3D printers, linked using open process automation standards. ASU offers a digitally integrated manufacturing setup that includes robotics, programmable logic controllers, smart sensors and RFID tracking for milling and additive manufacturing processes.

Edited by Puja Mitra, WTWH Media, for Control Engineering, from a University of Michigan news release.