Festo allocates 8% of revenue to R&D, focusing on compact automation for life sciences.

In an industry that values precision and efficiency, German automation company Festo is allocating 8% of its annual revenue to research and development. This investment amounted to approximately $400 million in the past year, according to Joshua Lamontagne, product market manager for LifeTech at Feso, during a recent WTWH media press briefing.

In 2024, Festo reported a turnover of €3.45 billion, a decline from €3.65 billion in 2023. The company allocated 8.8% of its revenue to research and development, totaling approximately €304 million, compared to 7.7% (about €281 million) in 2023. In previous years, Festo’s R&D investment was reported to be approximately 8% of annual revenue. The company holds more than 2,600 patents globally and develops around 100 new products annually that are considered for patent applications.

“This is cutting edge research, trying to develop new technologies and go into new spaces,” Lamontagne said.

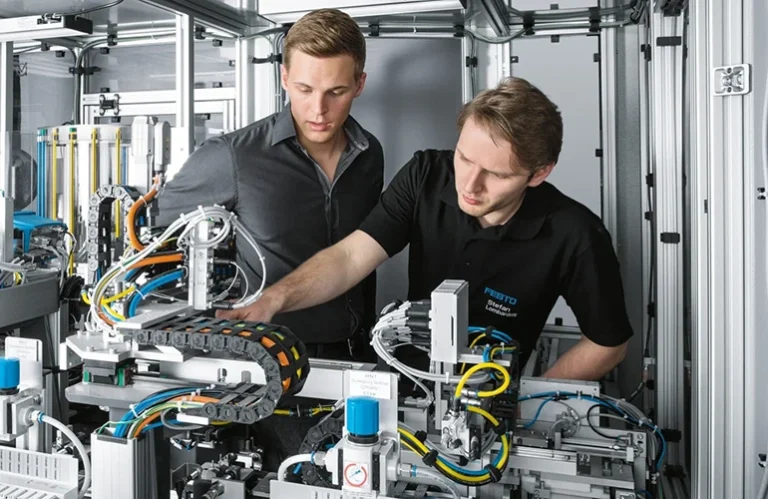

Headquartered in Esslingen am Neckar, Germany (near Stuttgart), the company has focused R&D investment on its LifeTech division since the early 2000s, noting connections between industrial pneumatics and the increased use of automated laboratory processes. It also maintains offices in locations such as Shanghai and the Boston area (Marlborough).

“What we saw is that these life science customers are looking to automate a lot of processes that are done manually,” Lamontagne explained. “With our strong background in factory automation and industrial automation, we had the skills required, or the knowledge required, to automate these laboratory or life science processes.”

Active in areas such as diagnostics and pharmaceuticals, Lamontagne shared an example of how Festo’s liquid dispensing technology helped address a client’s challenge with automated vial filling. “They were overfilling everything by 10%, but this could add up to tens of millions of dollars per year in wasted drug,” he said. By using more precise dispensing systems, the client was able to “tighten the band for that dispense” and save millions annually, Lamontagne noted.

Two decades of research address lab space constraints

Over the past two decades, Festo’s research has led to the development of technologies aimed at addressing common challenges in lab automation, such as limited space. “Laboratory space is very critical. All of the Festo Life Science products were designed with space-saving in mind,” Lamontagne noted. Lab environments require features like HEPA filtration and the ability to handle hazardous materials, which add to system complexity and cost.

The R&D efforts have resulted in developments such as media-separated valves, which Lamontagne describes as unique in performance: “There’s no other valve on the market that is this size that’s able to provide the flow rate that we do with media separation.” He adds that these valves are “about 100 times more leak-tight in gas than a standard pneumatic valve.”

At its Marlborough facility, Festo engineers have worked on reducing system size by integrating components. “We’re able to take 16 precision regulators and integrate them onto a single circuit and a single manifold to really save space for the customer,” he explained.

From manual approaches to automated precision for labs

The research focus aims to improve manual processes in life sciences that can be time-consuming and repetitive. Lamontagne illustrated the issue with an example: “You’d have somebody who would basically sit all day and twist open the vial, place it back on the rack, and then go through all day like that.”

To address this challenge, Festo developed the EHMD rotary gripper, a compact device capable of gripping and continuous rotation. Adapting their industrial experience to suit laboratory-scale automation involved adjustments in design and function. “With an electric gripper, you’re going to have slight heating up. With a pneumatic gripper, you’re not going to heat up at all,” Lamontagne explained, highlighting how Festo applied pneumatic principles to meet the temperature-sensitive requirements of lab environments.

The company adopted its piezo control technology, originally developed for industrial pressure regulators over the past 30 years, to design mass flow controllers capable of managing flow rates down to0.2 liters per minute, supporting its shift toward microfluidics applications. “Similar concepts as a product we’ve been providing for 30 years. It’s just that, instead of pressure control, we’re now controlling a flow in a system,” Lamontagne noted.

The company operates Technical Engineering Centers in Boston and Shanghai to support industrial and laboratory applications. These facilities evaluate customer-specific reagents and chemical processes, focusing on technologies that can be applied in areas ranging from bioreactors in brewing to semiconductor production.

“What I think is important with Festo Life Sciences is these life science products were designed with laboratory automation in mind, where space is really important,” Lamontagne reflected. “I think it’s great to see that space-saving go back into a factory automation example and work really well there.”

This Control Engineering article originally appeared on another WTWH Media publication, R&D World on July 16, 2025.

Edited by Puja Mitra, WTWH Media