Robotics technology is getting more sophisticated and capable of performing more tasks while also making them more human in their behavior and movement.

Robotics insights

- Automation in manufacturing, exemplified through robotics, enhances safety and efficiency. The integration of surgical robots in healthcare addresses treatable conditions, simplifies processes, and reduces costs.

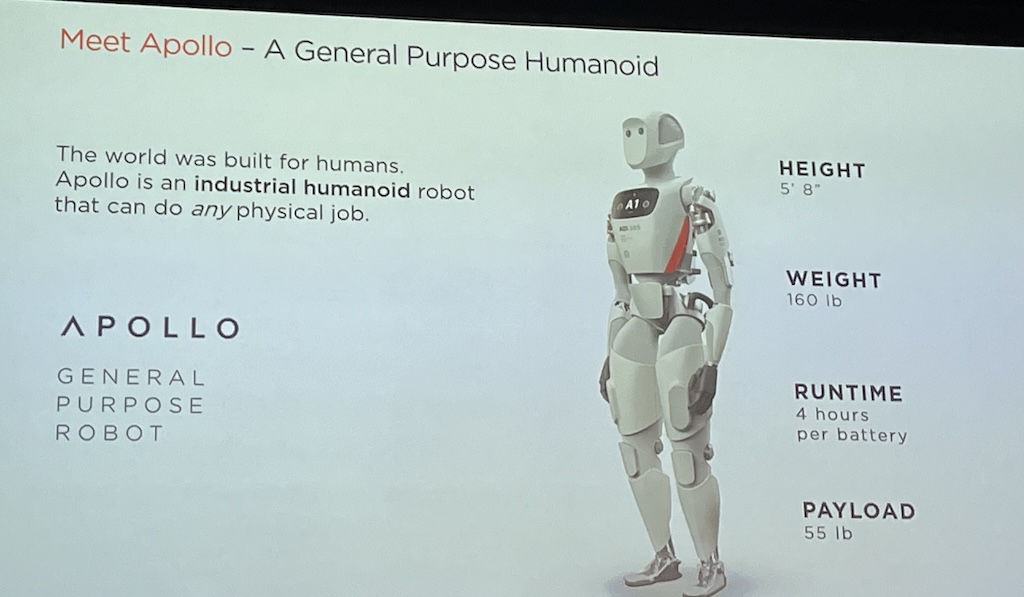

- Apptronik’s humanoid robot, Apollo, aims to revolutionize robotics by creating versatile, human-like machines capable of diverse tasks. Advances in technology and AI contribute to building trust in these innovations.

Robotics and automation are coming together to make manufacturing operations more sophisticated and powerful and capable of performing tasks once thought impossible or impractical. Robots are capable of working non-stop without a break and can handle the dull, dirty and dangerous jobs for humans while freeing them to do jobs better suited to their strengths.

“We don’t grow up wanting to work in a chicken factory. Future generations will want to be a robotic technician,” said Chetan Kapoor, head of optimization and automation, Tyson during the roundtable discussion “Automating the Future: Exploring Emerging Applications in Robotics and Automation” at the A3 Business Forum in Orlando.

Tyson, a food manufacturer, is well-suited to using robotics in a facility where safety is paramount. Kapoor said the USDA supports the science of robot integration in these facilities to promote human safety, which is always a major concern.

Success is dependent on prioritizing and measuring many aspects such as safety, quality, labor efficiency, maintenance reliability and more, Kapoor said. Everything has to come together and overlap with one another to help ensure success.

Martin Buehler, global head, Robotics R&D, Johnson & Johnson MedTech, is working on introducing surgical robots into the medical arena. The purpose, he said, is to try and help treat surgically-treatable conditions and help give the 5 billion people in the world who don’t have access to safe and affordable surgical health care.

The process is a long and arduous one even though surgeons are in favor of robots performing some surgeries because it’ll reduce the physical and mental load. It’s more a matter of optics and getting the message out.

“We really need to do a better job of investing in the clinical outcomes of these surgeries,” Buehler said.

Making robots more human

Robots have gone through many advances and have become ubiquitous in many industries as consumer demand goes and the need for more workers. The skills gap remains a huge issue in manufacturing and will continue to be so. Even if every person were to have a job in the United States, there’d still be millions left over.

Many robots currently working in the plant floor often come in the form of giant arms swinging around or vehicles driving around like cars. They don’t look like C-3PO from Star Wars or even some of the more human-like robots seen in movies such as the Will Smith movie I, Robot in 2004.

One company is looking to change that with a humanoid robot called Apollo. Jeff Cardenas, CEO of Apptronik, believes the day of robots that look and move like people is much closer than people realize.

“We make robots for humans. We build versatile robots to do work in the real world,” he said in his presentation “Humanoid Robotics: The Convergence of General-Purpose Robots and AI.”

While many robots in the plant floor are designed to do certain things very well, that’s a limiting on what they could do, which is what Apptronik is trying to achieve.

“We want to create one robot to do thousands of different things. We think humanoid could be the form factor to deliver on that vision,” he said.

Apptronik has been at work on this for two decades and the process has been a matter of trial and error and has come in different forms. Cardenas said they’ve worked on building up the technology such as actuators, real-time controllers and improving computation speed and enhancing its processing capabilities. All of these advances are striving to help create a robot that can move and interact with an environment like a human would and work in a collaborative way.

“They have to work successfully and people have to trust them,” Cardenas said.

Artificial intelligence (AI) advances also have helped with some of this, but it’s matter of putting the pieces together to create Apollo, which is the eighth iteration going all the way back to their Valkyrie model in 2013, Cardenas said.

Apollo is designed to do any physical job and is built and designed to look like an average human, listing at 5’8 and weighing 160 lbs. Its battery has a runtime of 4 hours and has a payload of 55 lbs.

“There’s a massive need for jobs and the technology is ready,” Cardenas said. “It’s cheap enough and good enough to where it’s financially viable at the price points we need.”

Might not be C-3PO yet, but Apollo could be a step toward that direction. Hopefully, though, it doesn’t have the fussy and eccentric behavior Threepio did.

Chris Vavra, web content manager, CFE Media and Technology, [email protected].