Smart water utility control systems and digital transformation: Learn how to apply artificial intelligence and machine learning in the water sector to create the ultimate AI/ML integration roadmap. See eight steps to integrating digital technologies and control systems.

Integrating control systems and AI/ML insights

- Identify operational challenges within water and wastewater utilities and explore how AI and ML technologies can address the challenges with real-time analytics and predictive capabilities.

- Understand how digital transformation can enhance existing SCADA, PLCs and control systems, without requiring a full system revamp.

- Learn a structured step-by-step roadmap for planning, implementing and scaling AI/ML initiatives, focusing on data infrastructure, governance and change management.

Control systems integrated with artificial intelligence (AI) and machine learning (ML) provide real-world benefits. Applications include predictive maintenance, energy optimization, improved water quality monitoring and enhanced customer service.

Create a detailed roadmap for integrating these tools with existing supervisory control and data acquisition (SCADA) and digital systems. Whether starting with one application or transforming a full network, utilities need to transform responsibly, efficiently and effectively, without disrupting the core mission of delivering safe sustainable water.

Why is SCADA and AI/ML integration needed?

Existing urban water and wastewater utility infrastructure is at a critical juncture. Because regulations are becoming more stringent in many developed cities across the United States and Europe, utilities are facing operational challenges to meet these regulatory requirements. Amid aging infrastructure, rising operational costs and unpredictable climate changes, utilities are expected to deliver uninterrupted service, ensure environmental compliance and optimize energy and resource use. This situation is particularly challenging in areas that are rapidly urbanizing, thus forcing utility providers to expand services under significant pressure while overcoming decades of existing issues. In this context, new tools are emerging with the potential to transform the future of the water sector including AI, ML and digital technologies.

Water utilities are undergoing a digital transformation that is beyond flashy visualizations and “trendy” innovations (Figure 1). This transformation is about resolving long-standing operational difficulties, such as leaks that waste billions of gallons of water, energy-hungry pumps, treatment facilities that are struggling to maintain compliance during adverse weather conditions, and asset failures that result in disruptions to communities. By employing AI and ML, utilities can benefit from their existing plant data—controlled and monitored using remote input/output (I/O) networks, programmable logic controllers (PLCs) and SCADA systems—to attain real-time insights and help inform decision-making. A combination of these technologies offers quantifiable gains in performance and cost-efficiency, from energy optimization to predictive maintenance.

Water utilities can use AI and ML to boost operational efficiency, optimize energy consumption, strengthen environmental compliance and promote predictive analytics. To accelerate facility benefits, demystify the process of digital transformation for integrating AI and ML into present-day control systems by presenting a clear roadmap and real-world examples. The straightforward goal is to take one digital step at a time and assist utilities in contributing to a smarter, cleaner and more resilient water service.

Where AI/ML is making headway: Practical applications

Within the water and wastewater landscape, AI and ML have advanced from theory to measurable and clear outcomes. AI and ML are being integrated into everyday operations to address operational inefficiencies, achieve cost savings, minimize environmental impacts and operate the plant safely. Current utility operations can and will be improved effectively and intelligently, without the need for a complete overhaul.

Leak detection is simple but costly; by employing AI models, utilities can examine flow and pressure data in SCADA to detect anomalies and initiate real-time alerts, thereby reducing the frequency of manual checks and complaints from customers. This approach has allowed cities to substantially reduce non-revenue water and to maintain assets.

However, efficiency is not the sole advantage provided by AI/ML. By monitoring water quality in real time, these tools can detect potentially hazardous blooms or contaminants before laboratory testing, thereby ensuring compliance with American Water Works Association (AWWA) standards and the Smart Water Networks Forum (SWAN). Digital twin simulations and AI/ML-based effluent control help treatment plants to significantly reduce greenhouse emissions while staying within discharge limits (which constitutes an essential step toward achieving net-zero goals). In addition, AI/ML helps utilities to operate faster and with fewer failures, thus demonstrating that data-driven systems are more dependable.

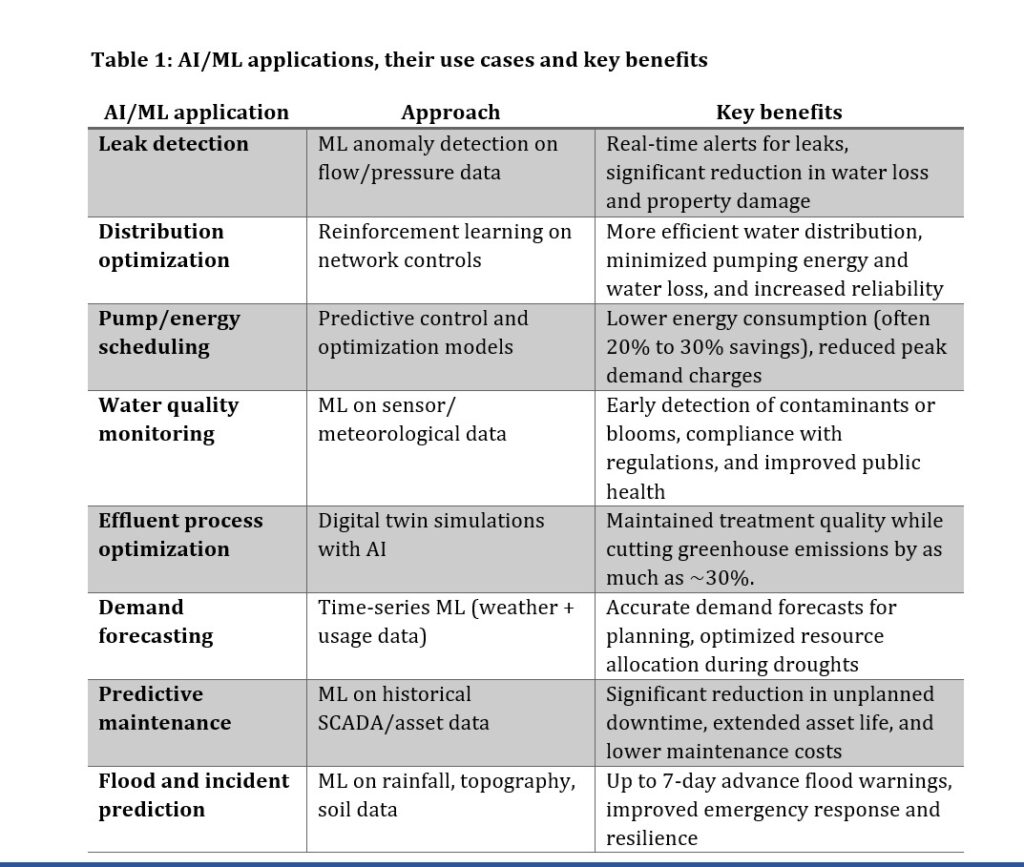

Based on real-world urban applications worldwide, Table 1 outlines the main AI/ML applications and the benefits derived. These applications contend that intelligent operations are not only feasible but are already happening. The following roadmap shows how to incorporate these capabilities into any utility.

Paving the future with AI and ML: A roadmap for water and wastewater utilities

Employing AI and ML in water and wastewater utility operations is no longer theoretical. AI and ML have demonstrated their ability to transform operations, improve reliability and promote better decision-making. Yet, the transition from inspiration to implementation requires more than just a desire; it demands an organized and planned approach that recognizes the legacy infrastructure already in place and considers the complexity and criticality of water and wastewater systems.

The infrastructure and systems that have powered water and wastewater utilities for decades are still serviceable operational backbones. Rather than replacing these existing systems, the goal is to equip and augment them with supporting digital technologies, which is the key to achieving this transformation. By purposefully integrating digital technologies, such as AI, ML and digital twins, into SCADA systems, utilities can evolve intelligently without necessitating costly upgrades or inconvenient service interruptions. This purposeful integration also allows developing cities to adopt and expand modularly in pace with their resources and requirements.

8 steps to integrating digital technologies, control systems

To integrate digital technologies, utilities should follow this detailed roadmap:

1. Every successful engineering project begins with planning and assessment. In the beginning, utilities need to perform a complete analysis. Utilities should consider questions such as:

- What do we have?

- What is working and what is not working?

- What gaps exist in the data?

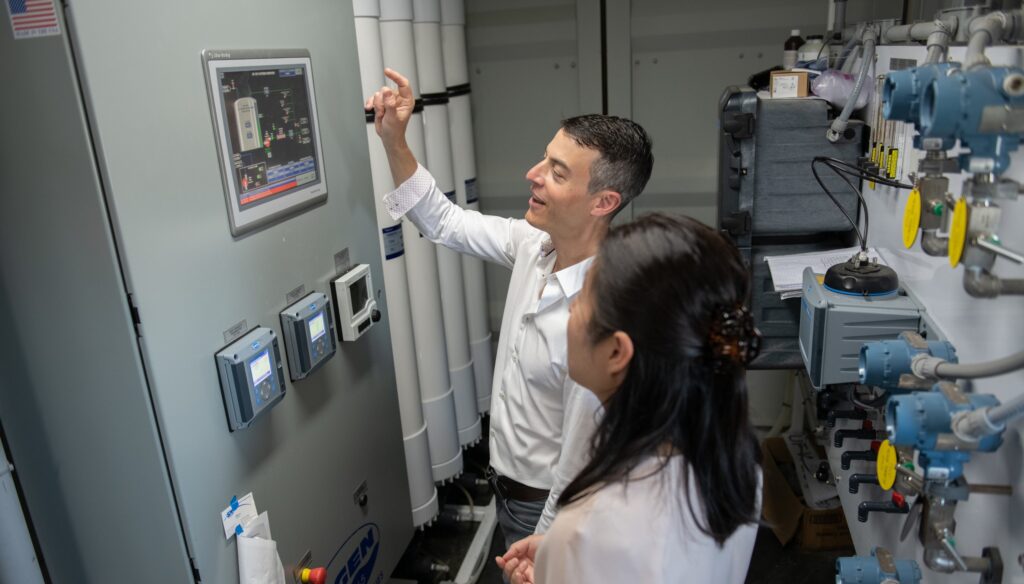

Aside from establishing the strategy for digital transformation, this preliminary assessment identifies immediate opportunities for improvement, such as developing predictive maintenance for an aging pump station or building AI models for leak detection. Most importantly, utilities must schedule upgrades in stages, preserving critical plant controls in place while also ensuring operators are involved from the beginning (Figure 2). Modernizing existing SCADA can be compared to “updating flight control system mid-flight.” It’s doable, but only with meticulous preparation.

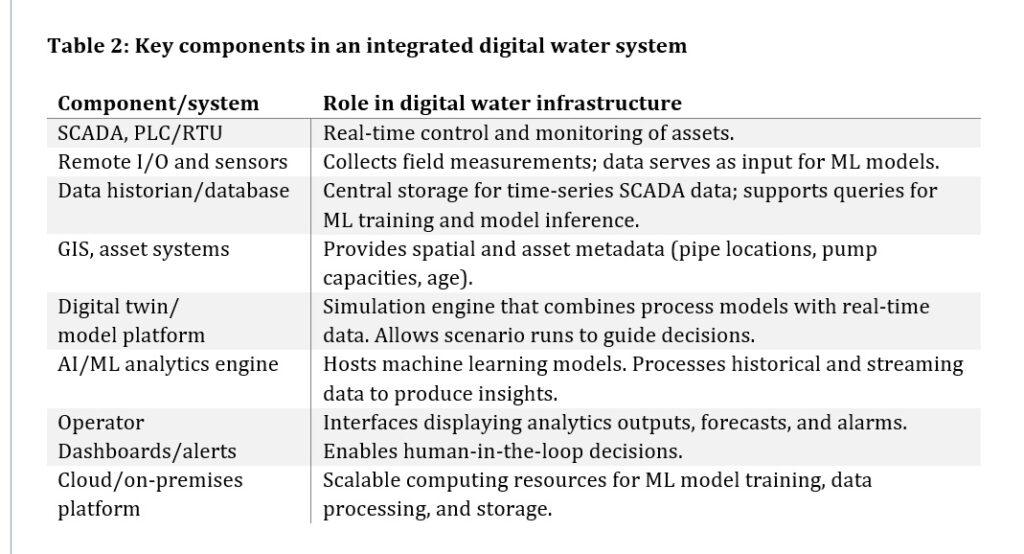

2. Once the priorities have been determined, the next step is to enhance the data management and integration framework, also known as the data fabric. SCADA infrastructure must be modernized to enable seamless data integration and access; this could involve updating existing PLCs with modern communication modules that can transmit data to either on-premise platforms or cloud platforms. Furthermore, information must not only be sourced from SCADA, but also from geographic information system (GIS) software, computerized maintenance management system (CMMS) maintenance logs and even customer usage data. Such a unified data ecosystem is the backbone of any AI/ML effort.

3. However, raw data alone will not be sufficient. Data must be refined, secured, synchronized and organized. Many digital projects falter at this point. In-depth pre-processing is a vital aspect of a well-executed data integration strategy. This includes filling gaps, denoising sensors and tagging historical events (such as storm surges or asset failures). Utilities must establish data standards, enforce access controls and secure their networks. When SCADA and information technology (IT) systems begin to integrate, the cyber threat landscape changes, making it critical to have robust governance and segmentation. It is at this point that guidance from AWWA and SWAN becomes crucial.

4. After all the required frameworks are laid, utilities can begin building and assessing AI/ML models. These models should start off small, such as building an AI leak-detection model trained on flow and pressure data or building an AI algorithm for predicting pump failures. In addition to usable data, success also depends on successful collaboration between data scientists and engineers. Domain expertise is essential for building models, detecting significant anomalies and adjusting thresholds to prevent false alarms. The models develop iteratively, thereby learning, improving and eventually generating actionable insights, regardless of whether the platform used to develop these models is simple or complicated.

5. At this point, a significant elevation is achievable by integrating digital twins. Using high-end visualization (HEV), a treatment facility can forecast outcomes in addition to simulating operations (for example, visualization can depict how the effluent quality and energy use is affected by altering the aeration rate). Digital twins combine real-time data with ML and physics-based models to further optimize the prediction outcome, such as the one used in Denmark’s TwiN2Ops project in a wastewater treatment plant. By incorporating this simulation layer, operators can formulate “what if” scenarios and determine results backed by data (not just conjecture). The digital twin becomes more intelligent over time as new data and deeper learning enhance predictions.

6. Next step would be to integrate the insights from the digital twin and AI/ML models back into operations. When doing so, it must be ensured that the AI does not take full control of operation, but rather that create a robust feedback loop. By using dashboards or key performance indicators, AI/ML models can notify operators with recommended SCADA control setpoint changes via open platform communications (OPC) or an application programming interface (API). Some utilities may enable AI to directly influence control parameters, but only with human oversight. In some cases, systems can be run in advisory mode, gradually improving the recommendations’ credibility. In all likelihood, operational integration will ensure that AI/ML is incorporated into everyday operations rather than merely being used as an external analytics tool.

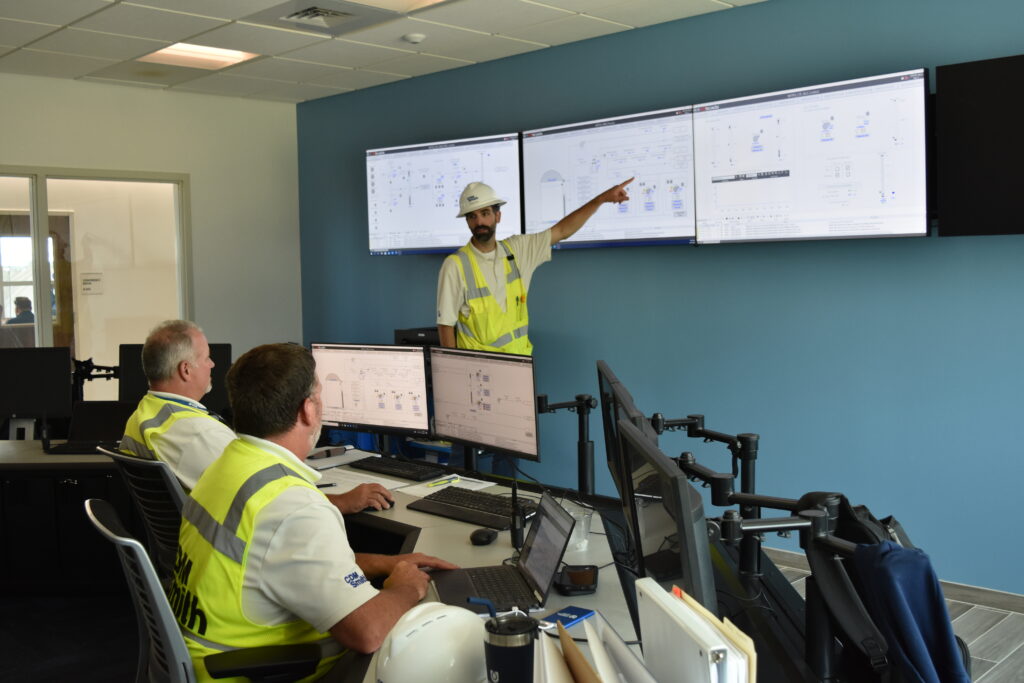

7. Undoubtedly, people must be credited for transforming utilities. The frequently overlooked key to success is organizational change management. Operators need to understand how to use dashboards, but they also need to be educated on the purpose and function of the algorithms. Cross-functional teams that combine IT, operations, asset management and analytics are vital for supporting and growing digital projects (Figure 3). Confidence is bolstered when a predictive maintenance model prevents an expensive unplanned outage or a leak-detection system conserves millions of liters of water. Each success contributes to building momentum.

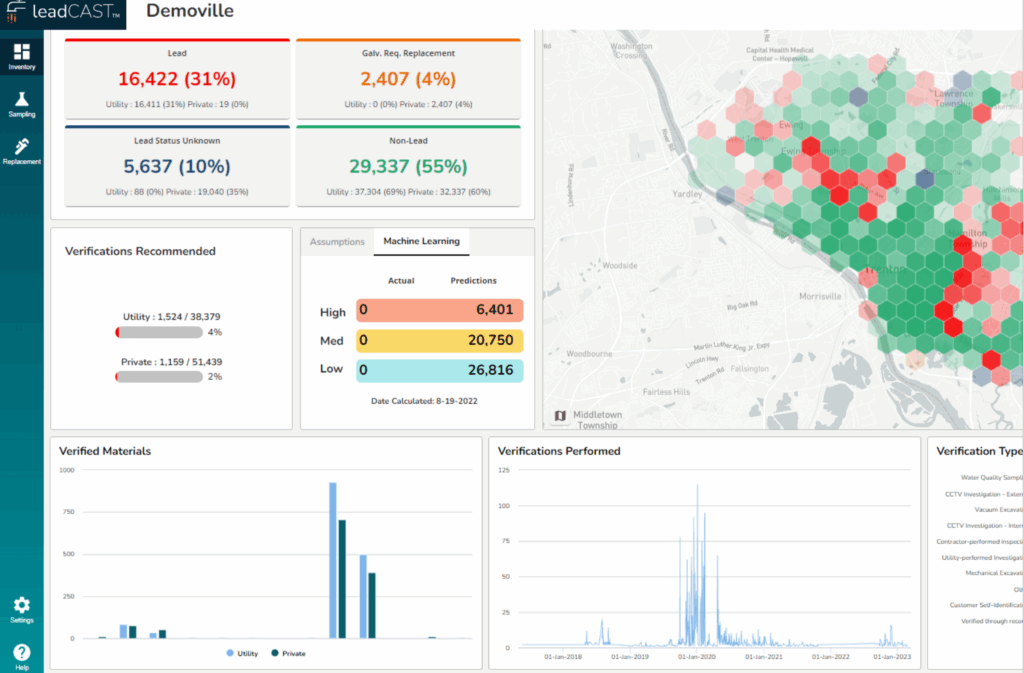

8. Interoperability is the final piece of any digital transformation (Figure 4). A future-ready digital utility must avoid proprietary hardware, software and protocols. Systems must be made plug-and-play by using open standards such as Open Geospatial Consortium (OGC) for geospatial metadata, OPC-UA for control data, and evolving technologies such as SWAN Digital Twin architecture. By implementing this approach, future investment is ensured and integration costs are minimized. Utilities can upgrade their platforms by adopting new tools and collaborating with third-party vendors without disrupting existing systems. This open modular architecture allows for incremental digitization based on available funding and infrastructure, thus maintaining long-term flexibility (which is particularly important for cities in developed and developing nations).

This roadmap can be adapted to the real-life complexities of utility operations, as opposed to a one-size-fits-all blueprint. For cities in North America and Europe, this helps to update aging infrastructure without causing major disruptions. It presents a modular way for developing cities to overcome legacy constraints. Additionally, it provides a clear achievable framework for utility professionals to fully use AI and ML. (See Figure 5, digital transformation roadmap.)

Moving control systems from a roadmap to reality

Integration of AI and ML into water and wastewater utility control systems signifies a fundamental change in the way critical infrastructure is viewed, managed and developed. Utilities can transform fragmented data and reactive operations into a predictive, adaptive and resilient future with a well-executed roadmap.

This digital transformation journey does not require a clean slate. On the contrary, it builds upon the capabilities of conventional SCADA, PLCs and field systems by enhancing them with intelligent layers of insight and automation. Utilities can maintain operational continuity while confidently entering a new era of digital capability that employs non-invasive methods without the need for replacing existing infrastructures.

The digital transformation process is not without challenges; cybersecurity risks, data silos and organizational inertia can all hinder progress. However, these challenges can be overcome with effective planning, governance and change management. Achieving minor successes (such as identifying a leak before it escalates into a significant issue, or forecasting pump failure several days in advance) fosters trust and generates momentum. These early victories show that AI augments human expertise rather than replaces it.

The roadmap is adaptable. A comprehensive digital twin with thousands of sensors and dedicated analytics teams could be the goal of a large metropolitan utility. In contrast, a mid-sized or emerging city utility may begin with simple anomaly detection in a few distant pump stations using an AI/ML model. Both approaches are effective and legitimate. The value lies not in the quickness of digitizing, but in the how deliberately it is done.

Ultimately, AI/ML are catalysts for improving customer service, promoting environmental stewardship and boosting operational efficiency. They also serve as catalysts for the creation of smarter cities that can adapt to resource constraints, rising demand and climate change.

Digital technology is the future of water management. By adopting a practical and human-focused strategy, utilities of all sizes and stages of development can effectively implement this vision.

Karthicraja Vellaichamy Munisamy is mid-level automation engineer; Vinoth Upendra Janardhanan is a senior automation engineer; and Srisylesh Balaji, is a mid-level automation engineer, CDM Smith Inc., Chennai, India; edited by Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected].

Read another article from Vinoth Upendra Janardhanan, CDM Smith Inc., on SCADA arrays.

See the Control Engineering AI/ML page for more learning.