Cover Story: VDW, the German Machine Tool Builders’ Association, said the first concrete OPC UA companion specification based on a realistic set of parameters will be presented at EMO Hannover 2019 in September. The interface allows data exchange from and among machines with different control systems. See more answers in “Flexibility in a marketable standard.”

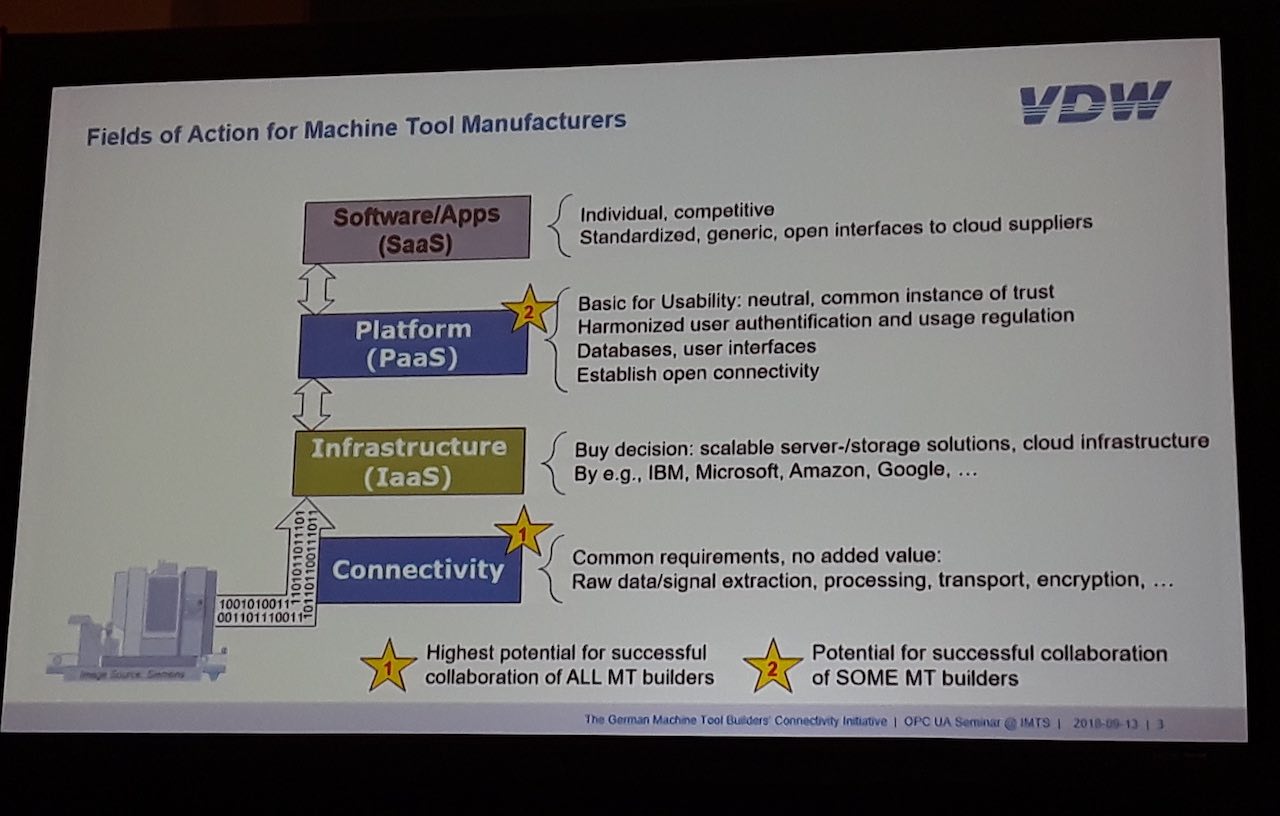

Global networking envisioned by Industrie 4.0 will only succeed if the data exchange takes place via standard interfaces over the entire process chain. Under the umati brand, the VDW (Verein Deutscher Werkzeugmaschinenfabriken – German Machine Tool Builders’ Association) is developing an open interface standard for connecting machine tools to higher-level information technology (IT) systems. This significantly simplifies digitalization and allows medium-sized companies to tap into the potential of modern production environments.

The interface will be demonstrated in a complex showcase at EMO Hannover 2019, Sept. 16-21, where 50 to 100 machines from national and international manufacturers will be linked via the first internationally agreed draft of the OPC UA Companion Specification.

VDW’s umati interface (universal machine tool interface), which is based on OPC UA (Open Platform Communications Unified Architecture), aims to ensure data from machines equipped with different control systems is routed through an open, standardized connection. It is comparable to a USB stick.

“It’s about creating something that the computer industry has long benefitted from,” said Dr. Heinz-Jürgen Prokop, VDW chairman.

Meeting customer requirements

Digitalization has long been part of the daily business of machine builders. Companies have had plenty of time to form expectations and ideas for the practical application of umati.

“At Profiroll, we’re currently concentrating on analyzing machine data to achieve ever finer tolerances while ensuring process reliability. In recent years, for example, we’ve developed a hardness compensation system that irons out fluctuations in the infeed material on the process side – an intelligent machine, so to speak. We don’t yet have large-scale processing of machine status data. We initially worked elsewhere within the VDW on developing the umati standard, since the in-house resources for software development are limited,” said Dr. Stephan Kohlsmann, managing director of Profiroll Technologies GmbH from Bad Düben.

“Our customers are increasingly demanding part-specific data and also information on the status of the machines and the quantities produced. We machine tool manufacturers know which information operators are interested in and are therefore ideally positioned to define a standard… [compatible with] control manufacturers. In the future, operators of a wide variety of machine tools can expect to receive the data they need in a uniform context, in a uniform cycle and in a uniform data format. This is a huge step forward because then they only have to take care of the specific, standardized storage and processing of data,” Kohlsmann continued.

Regarding the potential savings and improvements that can be achieved through a uniform interface standard, Kohlsmann said, “Today, machine manufacturers receive a set of requirements from each individual customer regarding the provision of key data in their own unique format. This is enough to justify time- and cost-intensive engineering processing and adaptation of software on a project-specific basis. The umati standard makes it possible to fulfil many different customer requirements. This is a revolutionary project in mechanical engineering and comparable to the new mobile transmission standard 5G which will enable developments such as autonomous driving, augmented and virtual reality or real-time applications to become part of everyday life.”

Dynamic future business models

Digitalization also is crucial at Samag Saalfelder Werkzeugmaschinen GmbH, a manufacturer of machine tools and automotive components.

“Internet of Things (IoT) or Industrie 4.0 are based on having knowledge of the data produced and its significance during the lifetime of a system, and also on the use of a common language which enables all system elements to understand each other. Samag Machine Tools creates the conditions for this through close cooperation with the development departments of the premium suppliers,” said Roland Emig, Samag managing director.

“Optimized, secure and standardized data access to the planning and/or control systems allows efficient utilization of machines and plants, avoidance of unplanned downtimes and optimized planning of availability and capacities,” Emig continued.

In addition, this common approach provides the basis for dynamic, future business models such as pay-per-use, predictive maintenance, smart monitoring, smart data services and capacity on demand.

“There is also considerable potential for easier exports through the immediate implementation of machinery and equipment in existing organizational structures without national adjustments. In addition, there is the potential to reduce the number of variants, the possibility to safeguard concentrated expert knowledge within the company, and improved release security and data security,” Emig said.

Global networking standard

The specification being created is based on OPC UA – a data exchange standard for manufacturer – and platform-independent industrial communication.

“The standard provides both a data model and a communication structure for implementing parameters and semantics in an open, standardized form. That’s why it’s spreading so rapidly, especially in mechanical and plant engineering,” said Dr. Alexander Broos, director of research and technology at VDW, explaining the technical basis.

The implementation is comparatively simple, since development packages can be used to configure and customize an OPC UA server. (See also “Flexibility in a marketable standard.”)

“The great advantage of OPC UA is that you no longer have to worry about how the machines communicate because OPC UA specifies the protocols and data exchange mechanisms. You can concentrate on what you want to communicate, because the data that customers are interested in varies from industry to industry, or even from machine to machine,” Broos said.

Uniformly defined parameters, which are described and published in the form of an OPC UA Companion Specification, play an important role. The standards are funded by the OPC Foundation, which supports the publication and dissemination of OPC UA standards. The OPC Foundation is an industry consortium that creates and maintains open connectivity standards for industrial automation devices and systems, and therefore represents a key partner. The VDW has been a member since June 2018.

Digitalization is a key topic at EMO Hannover 2019. The “IoT in Production” exhibition area offers a complete overview of key aspects of digitalization, such as industrial security, data analytics, industrial cloud services, process monitoring, predictive maintenance, artificial intelligence (AI), machine learning and Big Data management.

Flexibility in a marketable standard

Broos also explained the global challenges that need to be overcome in implementing a uniform OPC standard.

Question: What is the current status of umati?

Answer: We are currently working on umati 1.0, the first coordinated standardized semantic system, as well as specifications for their implementation. However, it is already apparent that umati will have to be refined, as is usual with software in the context of practical use cases. At some point there will be umati 1.1 or umati 2.0, or process-specific additions, such as for laser processing or woodworking. Putting this into practice is a complex process. In concrete terms it means reacting to changes, if necessary, with an update, in a relatively short time frame. This is generally not common practice in the area of standardization. In addition, we have to deal with various issues such as how to achieve downward compatibility, or how machines can be connected in the brownfield development, etc.

In addition to major machine tool manufacturers, we have brought on board important suppliers of computer numerical controls (CNCs) for machine tools. B&R Automation from Austria and Mitsubishi Electric from Japan have recently joined with Beckhoff, Bosch Rexroth, Fanuc, Heidenhain and Siemens.

Our newly founded OPC UA Joint Working Group (JWG), which started work in mid-February, is responsible for anchoring this throughout the industry, with machine manufacturers, suppliers and customers.

Q: Is umati a rival to the U.S. standard MTConnect?

A: Both umati and MTConnect are open interfaces. Umati is based entirely on the freely configurable OPC UA communication platform. OPC UA provides a framework which regulates how the machines correspond with each other. The precise content of the communication can be regulated individually by describing parameters in an OPC UA Companion Specification, which is a kind of dictionary. Umati and MTConnect are coordinating on developing this uniform dictionary. There are, however, some differences with regard to the implementation. Here, umati is striving to convert the special domain knowledge of the machine tool industry into semantics and an information model.

The OPC Foundation has a cooperation agreement with the VDMA. Under this, the VDMA, the largest network organization of its kind in Germany and Europe, acts as a German and European platform for all branches of mechanical and plant engineering and as a strategic partner of the OPC Foundation. Companies that want to implement OPC then use the sector-specific VDMA “standard sheets.”

The VDMA Robotics + Automation and Plastics + Rubber Machinery associations in particular have already developed their own standards. Others, such as packaging machine manufacturers, are also working on this. We in the VDW are therefore operating in an expert environment, are integrated into the processes of the VDMA and can benefit in the long term from the resulting synergies.

Q: What does this diversification mean for the manufacturers in the individual industries?

A: Of course, industry-specific standards are important, even unavoidable, for OPC UA. The different industries are too different for it to be otherwise. And there will always be manufacturer- or customer-specific data requirements that are impossible to standardize. Nevertheless, there is always a certain degree of overlap across all sectors. This should then be covered in a general section which is applicable to all industries. Corresponding agreement is reached within the VDMA, in which the VDW is also involved (with umati). Of course, this process demands a degree of flexibility from the individual participants in reaching the common goal: a standard that can be applied as universally as possible. However, I’m optimistic that we’ll move relatively quickly together towards achieving this.

Annedore Bose-Munde is a specialist journalist from Erfurt writing a press release for VDW. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media, [email protected].

KEYWORDS: Machine tools, connectivity

VDW and OPC Foundation aim to make a standard for data exchange from machine tools.

OPC UA Companion Specification will serve as a dictionary to and from machine tools.

umati 1.0, is said to be the first coordinated standardized semantic system.

CONSIDER THIS

Can your machines efficiently communicate with each other and with higher-level systems?

Online extra

EMO Hannover 2019, Sept. 16-21, is a trade fair for the metalworking sector. The theme is “Smart technologies driving tomorrow’s production.” The fair will be presenting the latest machines, plus efficient technical solutions, product-supportive services, sustainability in the production process, and other trends and technologies. EMO is a registered trademark of the European Association of the Machine Tool Industries, Cecimo. Learn more about EMO Hannover 2019.