Digital twins are transforming industries by streamlining design, testing and maintenance processes, reducing costs and improving productivity. By merging virtual and physical worlds, digital twins enable informed decision.

Digital twin insights

- Digital twins streamline design, testing and maintenance processes, reduce costs and improve productivity.

- Establishing a robust digital twin strategy requires addressing common challenges and leveraging opportunities to create value.

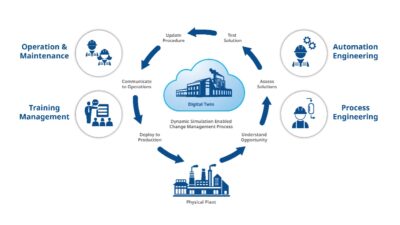

- Digital twins are virtual representations of physical assets, processes or systems across their lifecycle that use historical data analysis, real-time systems monitoring, simulations and emulations.

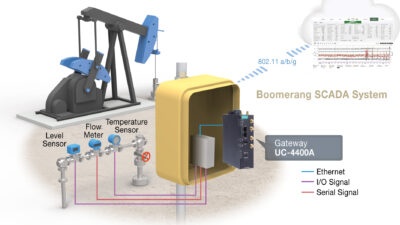

The rapid increase in data and connectivity over the past decade has created opportunities for many industries to harness digital transformation. The value of digital technology lies in its ability to integrate data from various business and operational systems (IT/OT), contextualize it and generate insights for optimal decision-making. As a result, organizations are increasingly focused on maximizing the value of that data using digital tools, like digital twins.

Digital twins are excellent virtual representations of physical assets, processes or systems across their lifecycle that use historical data analysis, real-time systems monitoring, simulations and emulations. These powerful tools allow organizations to lower operational risks, respond faster to changes, operate more efficiently and accelerate speed-to-operation by providing the means to virtually execute activities.

Building a successful digital twin strategy

To harness the full potential of digital twins, organizations must develop a robust strategy. This process involves understanding the key components of digital twin technology, addressing common challenges and leveraging opportunities to create value.

One of the first steps in a digital twin strategy is ensuring the models are user-friendly and accessible to personnel without advanced technical expertise. Organizations must create models that can be easily adapted to meet specific customer needs, facilitating customization and interaction.

Digital twins power use cases across the manufacturing lifecycle, including:

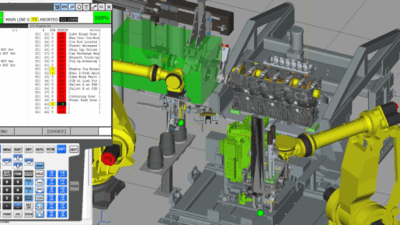

- Streamlining design and testing: Operational simulation, while highly effective for real-time feedback, presents challenges due to the complexity of numerous design choices. Digital twins streamline the design, testing and maintenance of machines through virtual simulations and real-time data analytics. Successful factory simulation projects require skills in data engineering, simulation engineering, domain-specific knowledge, and statistical analysis.

- Reducing commissioning time: Industrial manufacturers use digital twins to expedite the commissioning of new equipment and processes by creating virtual representations of physical assets. This approach to virtual testing, or virtual commissioning, has demonstrated a reduction in time to achieve steady-state operations by up to 40% compared to traditional methods. Virtual commissioning seamlessly bridges traditional and virtual development by leveraging digital twin technology to model and emulate engineering systems within a virtual environment.

This virtual replica of the physical system enables engineering teams to test and verify systems virtually, requiring less effort and significantly reducing the cost of design changes compared to physical commissioning. The engineering team can use this digital twin to test various system elements, such as programmable logic controller (PLC) code logic, software integration and user interface effectiveness. This approach allows a significant portion of physical testing – traditionally conducted on the shop floor – to be carried out virtually before the equipment is fabricated.

Capitalizing on digital twins’ opportunities

To simulate and emulate an entire factory, an organization can begin on a smaller scale and gradually expand. For instance, start with the material-handling system and progressively incorporate other systems until there is a comprehensive virtual representation of the entire facility, including equipment, materials and personnel.

Facilitating training

Digital twins support workforce training, enabling proper machine use and preparing operators for a wide range of incidents. Virtual training allows organizations to simulate faults and extreme conditions without risking physical damage. Engineers can improve user experience and reduce training time by gaining insights into equipment location and user interfaces for operator ergonomics before the physical system is built.

Optimizing and troubleshooting existing production

Organizations can speed up continuous improvement efforts by leveraging virtual environments for testing and optimization. These environments offer enhanced flexibility for quick iterations and scenario testing, reducing costs associated with physical prototypes and labor. Integrating analytics systems with digital twins enables real-time condition monitoring and analysis of asset performance, allowing manufacturers to predict failures and implement designed maintenance routines to reduce downtime and upkeep costs.

Implementing a digital twin strategy

To remain competitive, organizations must embrace digital twin technology. This process involves assessing current capabilities and aligning them with business objectives. For a successful implementation, focus on delivering immediate value while enabling the capabilities to be scaled across the organization. A recommended three-step approach includes:

- Design: Assess readiness, define a clear strategy, identify high-impact use cases and gather modeling assets.

- Develop: Build digital twin models using existing computer-aided design; replicate real-world movements with control logic, analyze and optimize control logic via simulation/emulation; and measure results to make refinements.

- Scale: Expand digital twin capability to more assets, systems and sites; transfer knowledge to resources that will own, operate and maintain models; increase adoption across all functions; and measure and realize enterprise-wide value.

Collaboration and alignment among engineers, original equipment manufacturers, end users, designers, integrators and other stakeholders are essential for developing effective and sustainable systems. Gaining executive support for digital twin initiatives is crucial and can be achieved by aligning project outcomes with corporate goals. It’s important to consistently communicate this linkage to secure funding and support, especially in tough economic times. Demonstrating quick wins, presenting a solid business case and providing a clear rationale for long-term success are also key. Manufacturers that embrace a holistic digital transformation approach will scale quickly, build resilience, grow rapidly and capture market share.

How to avoid common digital twin pitfalls

Organizations that struggle with digital twin strategies often restrict models to single-use cases, limiting scalability and long-term benefits. It is crucial to manage models throughout their lifecycle to ensure their relevance. Developing adaptable models and avoiding rigid internal processes can help prevent inefficiencies and missed opportunities for value creation.

Navigating the future of digital twins

As the digital landscape evolves, organizations must optimize their digital twin strategies. This process includes building the right technology partnerships and continuously refining their approach to maximize value creation and achieve business goals. Digital twin technology is not just a trend; it is a vital tool for differentiation, growth and long-term success.

By embracing digital twins and developing a robust strategy, organizations can drive operational efficiency, enhance customer relationships and unlock new business opportunities. Keep in mind that digital twin applications are dynamic rather than static. They are living assets that adapt and grow with your evolving needs. Over time, these digital twin assets can be harnessed to achieve significant breakthroughs.

Leo Moran is a senior manager at Kalypso: A Rockwell Automation Business. Edited by Sheri Kasprzak, managing editor, Automation & Controls, WTWH Media, [email protected].