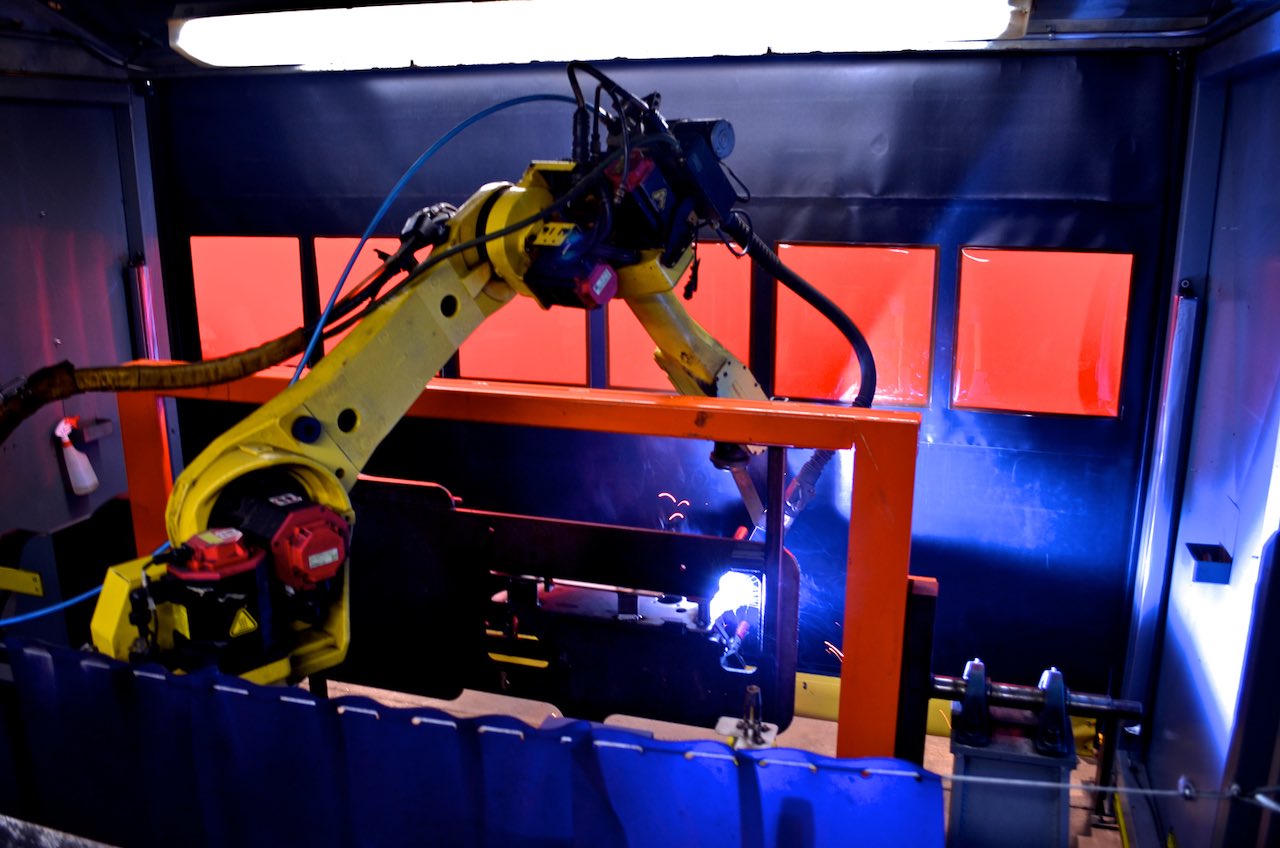

Machine safety: Physical barriers are often the best choice after a risk assessment is performed in places where machines and workers co-exist.

Any time a manual task can be turned into an automated one is a major operational efficiency boon for a facility, but without adequate safety measures, risks may exceed what’s acceptable. As order fulfillments speed up to meet the demands of internet-shopping customers, facility managers look for any edge available.

Machinery can perform arduous yet necessary tasks at much faster rates and typically with greater precision than human workers. Automated operations, like stretch wrapping, can be done much quicker than a worker can do his or her own. Considering there are more than 1.5 million industrial robots working across the globe, it’s a sure bet production would plummet without their use in today’s world.

Unfortunately, there is risk in cases where machines and workers co-exist. Facility managers who implement new equipment need to be aware of these risks and think about safeguards to protect their employees. This isn’t just best practice; it’s the law.

Understanding regulations

The point-of-interaction between robots and workers, like “running” a machine, is where the most risk and regulatory confusion often exist in a plant.

The best starting point is OSHA. Per 29 CFR 1910.212(a)(3)(ii), OSHA’s General Requirements of All Machines, the process at critical interaction points must be guarded or contained to protect workers from injury.

The rule states, “The point of operation of machines, whose operation exposes an employee to injury, shall be guarded. The guarding device shall be in conformity with any appropriate standards therefore, or, in the absence of applicable specific standards, shall be so designed and constructed as to prevent the operator from having any part of his body in the danger zone during the operating cycle.”

In the OSHA General Duties Clause in section 5:

(a) Each employer:

(1) Shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees;

(2) Shall comply with occupational safety and health standards promulgated under this Act.

These OSHA regulations make it clear safety cannot be ignored. However, as processes continue to advance and technology outpaces regulations written nearly half a century ago, new guidelines are being developed and referenced in best practices.

The Robotics Industries Association (RIA) R15.06 Industrial Robot Safety Standard is one such regulation. It references ISO 10218-1 and 2, Safety of Industrial Robots and Robot Systems, which address robots, robot systems and integration. RIA 15.06 was written in an effort to harmonize standards already in place in Europe. At its core, the standard requires better hazard identification, taking into account robot motion and the specific task being performed. Under this standard, safety-rated motion can be programmed using software that controls a robot’s operational area and the speed it can move at.

Risk assessments come first

RIA R15.06 requires risk assessments. Aforementioned, point-of-operation guarding is perhaps the trickiest aspect of this regulation; it represents the intersections of human and machine, as well as safety and efficiency.

Many details need to be considered when assessing this area. Some include the layout or design of the process, the limits of the system, as well as properly identifying all associated hazards devising methods for hazard elimination and risk reduction.

The distance formula as identified in OSHA guidelines can assist in determining the best machine-guarding device.

The formula is DS = K (T) + DPF.

DS stands for safety distance; K stands for the maximum speed an individual can approach the hazard; T stands for the total time to stop the hazardous motion; and DPF stands for the depth penetration factor of the safeguarding device.

Per this formula, the safeguarding product has a prescribed location based on a number of factors, including secondary hazards that might harm a machine operator. This formula makes a big difference in determining which safeguarding device a facility should implement.

Point-of-interaction safety

The most basic devices used for safeguarding manufacturing operations are light curtains, laser scanners and other presence-sensing devices. Once the infrared beams of these devices are tripped, the automated process ceases.

In many instances, these devices provide acceptable safety. However, they’re not always the best choice in all applications, especially after a risk assessment is performed. One of their biggest shortcomings is workers must adhere to OSHA’s distance formula to reduce risk of injury. This can lead to larger work cells, which leads to additional time for employees to walk between the non-operational machine and the safety area when the machine is operating. Employees who skirt the system with shortcuts compromise their own safety. Additionally, an employee who enters a work cell still can be at risk of injury from roll inertia as a machine powers down.

Automated barrier doors

A fast-acting automated barrier door or roll-up curtain is often the best choice because either one can eliminate exposure to both the dangerous movement of the machine and secondary hazards produced by the process, potentially eliminating risk and the severity of exposure.

When coupled with safety interlocks (up to PLe, Cat. 4 per EN ISO 13849-1 Machine Guarding when integrated properly), automated barrier doors and roll-up curtains offer an increased level of protection for point-of-operation guarding.

They restrict access to the process and contain secondary hazards such as smoke, flash, splash, mist or flying debris associated with automated welding operations by placing a barrier between machine operators and machine movement. These types of guards, in many situations, are an ideal alternative to light curtains and other presence-sensing devices.

Safer, more efficient automation

OSHA’s safety distance formula doesn’t apply to interlocked automated barrier doors because there is no depth penetration factor—allowing the safeguard to be placed much closer to the hazardous area. This correlates to less space being dedicated to a “safety zone” and results in reducing the manufacturing cell’s footprint.

Eliminating accidental entry into the cell is another benefit of interlocked automated barrier doors. Unlike the invisible infrared beams of presence-sensing devices, barriers provide safeguarding that can be seen. The physical separation they provide is a clear visual indicator the machine operator needs to be on task.

Properly guard machine operations

Facility managers need to always be looking for new technology that can accelerate operations. However, they also must keep safety at the forefront of any decision. A risk assessment to determine the best machine guard is the first step. After the choices have been narrowed down by safety requirement, consider the safety option that interferes with productivity the least-physical automated barrier doors.

John Ritter, product manager, Rite-Hite Doors. Edited by Chris Vavra, production editor, Control Engineering, CFE Media, [email protected].

MORE ANSWERS

Keywords: Machine safety, worker safety

Companies should use a risk assessment to determine the best machine guard for their facility.

Machine guards, while useful, aren’t always appropriate and their use should be determined case by case.

Physical automated barrier doors interfere with productivity the least and should be one of the first choices.

Consider this

What applications and industries benefit most from physical safety barriers?