Industrial motors and drives and the motion systems they are in are huge opportunities for industrial sustainability efforts and carbon-dioxide reductions. Video with three motor and drive experts expands on a Control Engineering three-article series.

Industrial sustainability, motors, drives and services insights

- NEMA motor efficiencies help drive industrial sustainability.

- Industrial motors can help decarbonization strategies.

- Industrial motor services can help sustainability efforts. More information related motor-drive efficiency topics is available in a Control Engineering video and articles.

This Control Engineering video interview discusses how motor-drive energy efficiency helps with industrial sustainability goals. Three experts are in the video discussion on motor and drive efficiency and industrial sustainability in three major ways.

- Benjamin Hinds is the vice president of product management and marketing at the NEMA Motors Division of ABB, and author of the Control Engineering article, “How to meet sustainability goals, part 1: High-efficiency motors.”

- Michael Basler serves as the local division manager for the System Drives Division at ABB in the United States, and he’s the author of “How to meet sustainability goals, part 2: The drive for industrial decarbonization.”

- Rob Snyder is local division manager, ABB U.S. Motion Services Division, and author of “How to meet sustainability goals, part 3: Examining roles of motion services.”

- The interview begins broadly with input from all three experts discussing the two sustainability deadlines, 2030 and 2050, and why industrial motor-drive efficiencies are important for those deadlines.

How NEMA motor efficiencies help industrial sustainability

Hinds answers questions two through six.

- Please expands on how high-efficiency motors reduce costs, achieve greater energy efficiency and cut carbon-dioxide emissions.

- Energy metrics differ significantly with smaller versus larger motors. Please explain.

- How have energy efficiency standards from the National Electrical Manufacturers Association (NEMA) and the International Electrotechnical Commission (IEC) helped motor manufacturers improve sustainability?

- Where can industrial facilities find motors that should be replaced with high-efficiency offerings? Waiting for a deadline or for a motor to wear out may not be the best strategy?

- What are some cost savings estimates for switching to high-efficiency motors?

Industrial decarbonization strategies and how motors can help

Basler addresses questions seven through 12.

- Decarbonization strategies for carbon-intensive applications emphasize the need to address energy usage in industrial sectors. Where?

- How can looking at decarbonization strategies in four areas of renewable energy, electrification, emerging applications and energy efficiency help and why?

- Please explain more about how renewables are helping to provide cleaner electrical power.

- How is electrification helping sustainability efforts?

- What emerging applications are contributing and how?

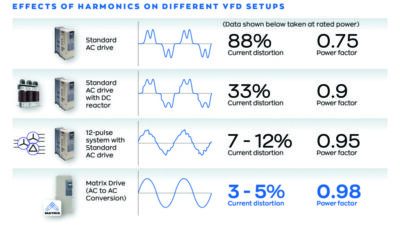

- Energy efficiency goes beyond high-efficiency motors. What else should industrial facilities consider?

How motor services can help sustainability efforts

Snyder examines how motor services help sustainability in questions 13 through 17.

- The third article looks at the pursuit of efficiency and the consistent need for optimization of energy consumption, looking at how motor and drive motion services can help. Please explain a little more.

- What kinds of audits can help and how?

- Please explain how continuous automated monitoring of motor-drive powertrains helps predictive maintenance and how that all ties to sustainability with sensors, software and real-time analytics.

- What lifecycle considerations important to investment justification, past traditional capital costs?

- What are commonly overlooked metrics that industrial motor-drive services can provide?

More information on motor-drive efficiencies

The interview concludes by providing additional resources on these topics.

- Where can people go for more information?

See the online section below for links and resources mentioned in the video.

Mark T. Hoske is editor-in-chief, Control Engineering, WTWH Media, [email protected].

CONSIDER THIS

Are you helping your industrial sustainability strategy to reduce carbon emissions with industrial motor-drive and motion-system efficiencies?

ONLINE

Control Engineering article series is explained and expanded in a ControlEngTV video interview.

- How to meet sustainability goals, part 1: High-efficiency motors

- Benjamin Hinds is the vice president of product management and marketing at the NEMA Motors Division of ABB https://ABB.com and https://baldor.com

- How to meet sustainability goals, part 2: The drive for industrial decarbonization

- Michael Basler serves as the local division manager for the System Drives Division at ABB in the United States https://new.abb.com/drives and https://new.abb.com/news/detail/101654/abb-invests-170-million-in-the-us

- How to meet sustainability goals, part 3: Examining roles of motion services

- Rob Snyder is local division manager, ABB U.S. Motion Services Division

- https://new.abb.com/service/motion and https://global.abb/topic/ability/en

- Expert video interview: Three ways motors and drives help industrial sustainability