As new hardware and software enters the market, manufacturers must prioritize efficiency and adaptability to stay relevant. Luckily, artificial intelligence (AI)-powered technological advances are here to help them stay nimble.

Industry 4.0 insights

- As we enter Industry 4.0, manufacturers will continue to see a clear need for agile and data-driven decision making that only AI-powered innovation can satisfy.

- Operationalizing smart asset monitoring, maintenance and inventory optimization practices will continue to fuel efficiency and adaptability in the industry.

The manufacturing industry has long been a trailblazer, from developing entirely new technology to finding creative applications for existing tools and processes. Innovation has been the industry’s maxim since the first industrial revolution — and that remains true today.

As we enter the fourth industrial revolution — marked by data and artificial intelligence (AI)-powered automation — manufacturers face new challenges. The amount of new hardware and software proliferating across plant floors and supply chains, alongside the real-time data they generate is difficult to keep pace with. Consequently, many can become overwhelmed, not knowing where to focus or how to harness all the information.

While some struggle to strategically and effectively integrate generative AI into their business, those manufacturers that establish a robust data strategy first will continue to see positive results. Specifically, those businesses that leverage technology in categories like AI-powered maintenance workflows, smart asset monitoring and inventory management are boosting their ability to make sense of it all.

The importance of AI-powered maintenance

The notion of automation isn’t new to manufacturing. Tools like the loom have been boosting productivity for millennia. Now, AI-powered automation tools are taking productivity to the next level.

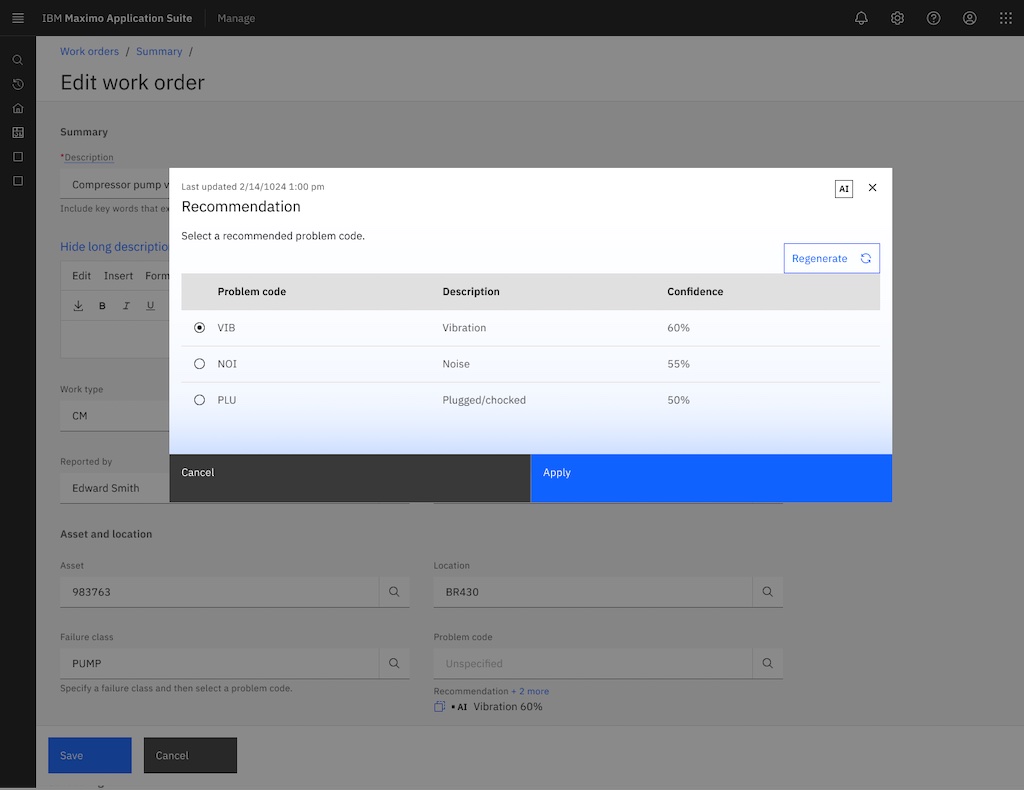

One clear example of this is how generative AI can streamline the process of identifying problem codes to efficiently resolve work orders. In the past, when an asset experienced any issue, maintenance managers would often need to manually identify the right failure code to deploy the right tools to address it.

Now, manufacturers can leverage innovative software that automatically suggests potential failure codes alongside a predictive confidence score that helps employees understand how confident the AI model is of the suggestion. For example, the tool may suggest with 75% confidence that the machine issue comes from an unexpected vibration. The maintenance manager can confirm this and select the code or choose to override it based on their expertise. This saves users significant time combing thought potential issues and allows them to quickly move on deploy the right technician to fix it instead. Not only that, but the same work order can be used to further train the model helping it achieve higher confidence scores in the future.

Looking ahead, this type of technology has the potential to evolve to make data recommendations beyond failure codes. Thanks to generative AI, software will continue to help organizations improve data quality, enable faster data entry and insights.

Smarter asset monitoring through new technological innovations

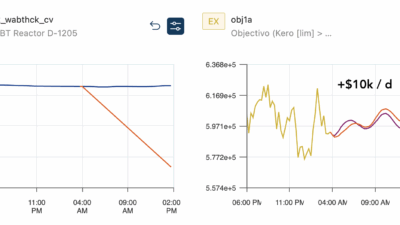

Another process that has been transformed by recent technological innovations is how manufacturers maintain their property, plants and equipment. A few decades ago, it was not uncommon for personnel to physically observe and record a machine’s performance metrics. Now, thanks to technology powered by internet of things (IoT) and advanced analytics, employees can easily get a full picture of an asset’s performance, compare it to custom key performance indicators (KPIs) and engage in a deep root-cause analysis to resolve any discrepancies.

What does this look like in practice? A good example is through IBM’s work with Sund & Baelt. They own and operate one of the largest bridges in the world, including the Great Belt, an 11-mile bridge and tunnel combination that is the largest construction project in Danish history. Given the magnitude of this asset, the company often had to deploy mountaineers to scale the side of the bridges and take pictures for manual inspection which was timely and not sustainable in the long term. They needed to modernize their inspection process, and collaborated with IBM and leveraged our AI-powered visual inspection solution that gathers data from drone photographs to monitor status of the bridge with no need for human inspection. Thanks to these streamlined inspections, Sund & Baelt can now identify what maintenance needs to be done faster and anticipates extending the lifecycle of the Great Belt Fixed Link bridge by 100 years.

How AI revolutionizes inventories

To revolutionize their operations, manufacturers should also pay attention to their inventory. Quickly changing customer demands can be difficult to reflect in assembly lines across factories and even the world.

Organizations that truly embrace smart manufacturing need to embed technology that for building adaptable supply chains. Cloud-based smart inventory platforms can be helpful for manufacturers in fast-paced industries since they allow drive better stocking decisions and easily change their production targets in near-real time. This can help rebalance inventory, create an all-encompassing auditable trail to record changes and run “what if” scenarios before changes in production are committed.

Leveraging this technology will continue to provide manufacturers with the tools they need to embrace the next industrial revolution.

Manufacturing challenges and what’s ahead for AI

As manufacturers seek new ways to overcome the data challenge, it’s clear that those who leverage technology to supercharge their data will stay ahead of the curve. Manufacturers should be cautious of incomplete, biased or otherwise problematic data that can skew decision making. Not only that, but when AI is built atop poor-quality data, its outputs are poor quality, too — and can undermine revenue and reputation alike.

By implementing technology that can track and generate work orders, make supply chain recommendations and more, manufacturers can ensure they are capturing and analyzing quality data that allows them to make well-informed operational decisions. Then, they can easily train their AI models on these previously vetted data sets to ensure they are providing even better suggestions.

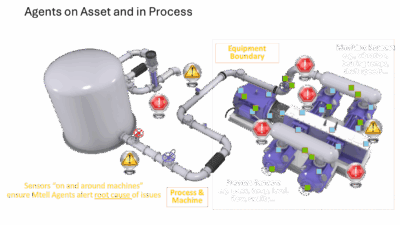

Industry 4.0 is the latest industrial era, but it won’t be the last. As manufacturers deploy the latest AI technologies across their plants and supply chains, they should also plan. AI agents — capable of tackling complex processes autonomously — are already making appearances and further innovation is on the horizon.