A few basic differences between control engineers and others in the plant can hinder progress toward optimization. Start a conversation to improve communications and controls. See examples and career advice. Send a link to these seven things other people should know about control engineers, so they understand.

It is no wonder "others" do not understand how to interact with control professionals. Control engineers may well be the least understood group in our society today. The U.S. government has more than 50 job codes for IT professionals but NONE for control engineers. Alaska does not offer a Professional Engineering License in control. Are control engineers part of chemical or process? Are they electrical or instrumentation? Having enjoyed over 35 years in this fulfilling arena, allow me to offer seven things "others" should know about this chosen profession.

1. Process engineering is steady-state; control engineering is real-time.

Process engineers pick setpoints and targets: 85 tons of wood chips plus 20,000 gal of chemical at a specific temperature for a certain length of time yields pulp with predictable properties. Control engineers, on the other hand, do not care about chemistry. Control cares about transfer functions and response times of the elements affecting the reaction: if the valve moves, how fast does the process change and by how much? If a different chemical is used by the process folks, odds are a least one response time will change and the loop will need to be retuned.

Process engineering is NOT control engineering. Do not assume a process engineer will succeed as a control engineer. Example: A chemical company was simultaneously setting both production and quality records on its most profitable product. A manager with a process engineering background decided a control valve was moving "too much." He ordered the valve to be locked down at its average position. He hoped to make an additional $200-500 per month on increased sales of a by-product. When the control engineer questioned the impact of the change, he was told he was being territorial, and perhaps had a personality conflict. Over the control engineer’s objection the change was implemented.

Rejects increased dramatically, often changing with the ambient temperature. Within a month this once most profitable product was losing over $10,000 per day! The control engineer pointed to the change in the control strategy and the corresponding start of the problem and asked to run a simple and most basic trial with absolutely no risk: Put the original control back.

Process engineers and research scientists dismissed the idea since average temperatures, pressures, etc., remained the same (but those variables were swinging constantly). The requested trial was specifically forbidden. It was stated emphatically, "The control was NOT the source of the problem." The control engineer was excluded from the biweekly meetings on the problem. The problem continued for 6 months. Every time the product was scheduled to run, they doubled management presence around the clock (with no effect on the rejects). Finally, the plant ran for 3 days with 100% rejects. Marketing decided to discontinue sale of the product at the end of the quarter. At that point the control engineer went directly to the plant manager, pleaded his case, and then ran the trial. The problem immediately disappeared. Process engineers (even PhDs and scientists) are not necessarily control engineers.

2. Computer geeks are not control experts.

This is an easy mistake to make. The control people live in a world of human-machine interfaces (HMIs) and "block-ware," using a PC interface. Many people with process control on their business card are not control engineers. A control engineer can calculate the flow through a relief valve. A control engineer knows the effect of load swings versus source swings on the design and tuning of a control loop. A true control engineer will not spend a week trying to tune a simple flow loop while standing next to a check-valve that is mounted backward in the line.

If you know of or are a computer whiz in a control position, welcome to a fabulous field. Please start learning control. There are many sources of control training available, and this training will pay huge dividends. Every company can benefit greatly by getting this control training for employees who need it.

3. Physics rules.

While driving down the road, if the back of your car passes the front of your car, you are unstable and in trouble; the back should not go faster than the front. Likewise, the control cannot go faster than the process. Put a loop in manual and give the valve a step-change. If the process shows no change for 2 minutes and then gradually rises over the next 30 seconds until it stabilizes, you cannot use that control for disturbances that occur faster than 2 minutes. Increasing gain and decreasing poll-time will not speed up the process response. When the process response is too slow, the loop must be reengineered. Relocate sensors, find sensors with faster response, use feed-forward controls, and discover other process relationships to predict control. This is the very heart of a good control engineer. This is the type of situation where process and computer folks have problems acting like a control engineer.

4. Senior control experts know things they do not teach in school.

Good control strategy beats more expensive instrumentation. This statement may upset some, but it is another example of where a true control expert can perform where others will fail. Consider consistency, density, or temperature control. Putting a $45,000 transmitter on the main flow to directly drive the valve on the controlled flow (sweetener or dilution) is standard practice from virtually every major engineering company. It is very simple, and it is very wrong. This is the loop requiring retuning repeatedly for years and years with no success. Why? The process variable deviation may occur due to an incoming change (such as an inlet temperature change), or a header pressure change may cause a change in the controlled flow, or a production rate change may necessitate a step change in controlled flow.

Each of the three error sources requires different tuning. One size does not fit all. In fact the main control (correcting for a change in inlet value) is production rate dependent: what works at a high production rate oscillates at a low rate, and what works at a low production rate is too slow at a high rate. Control will always be poor. Instead, take a simple $600 sensor but add an orifice plate/differential pressure (DP) transmitter on the sweetener/dilution line, and things improve. Flow control on the control line eliminates flow errors due to any header pressure changes. Ratio that flow to the main product flow and production rate errors disappear, and tuning the main variable is no longer rate dependent. Now control the ratio setpoint with the consistency, density, or temperature sensor, and you have a very simple to tune, robust control that will outperform the expensive instrument. Senior control experts know this; I haven’t heard of a school that teaches it.

SEE more, next page.

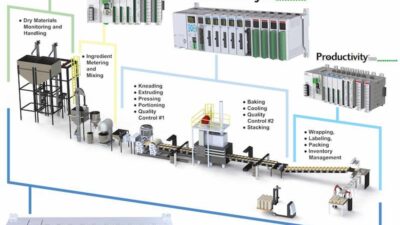

5. How to pick a process control system (PCS): Total installed cost (TIC) rules.

TIC includes the purchase price, programming, training, spare parts inventory, and maintenance for the next 10-15 years. The upfront cost is virtually always the least significant cost in the TIC. An increased number of maintenance contracts, spare parts, and required training all point to reducing the differences in the control systems in the plant. Fewer different systems almost always result in greater savings. Process improvement savings are hard to calculate, often obscured by process noise. Eliminate a $300,000 maintenance contract for a $50,000 increase on another existing contract, and you have real, provable savings.

Corollary to the TIC rule: Having fewer systems leads to far greater productivity from one of the scarcest resources: the process control group. All the major systems today can control the process, so go for the savings, not an emotional attachment to a legacy control system.

6. The PCS choice must be made by an expert in control systems.

Production/management want to pick the PCS—it’s a sexy decision and they have the power. That’s nice. For my part, I want to hit a world series-winning home run, but anyone who calls on me to do that should be fired. The probability of my success is infinitesimal; the team needs a major league hitter. The same holds true for picking a PCS. Today most products have morphed into a hybrid, hence the PCS label. There are greater differences between some distributed control systems (DCSs) than between some DCSs and some programmable logic controllers (PLCs). HMIs are so flexible, with moderate effort it is impossible for an operator to know which PCS is under the hood. I have worked on systems where a single operator station controlled seven systems from five vendors, with all differences invisible to the operator.

Operations is completely unaffected by which PCS is chosen. Operations is completely unaffected by which PCS is chosen. (Need I repeat it again?) Most systems can be configured making hardware reliability secondary to MTTR (mean time to repair). Process control and maintenance personnel are greatly affected by issues with distributed component object model (DCOM), use of OPC, tunneling, bandwidth, bus protocols, server-based HMIs, and many more issues that are at the heart of system differences. These are areas in which operations personnel are not competent. Control folk don’t tell operations, "Use the pretty pink chemical instead of the shiny blue-green gel," so please don’t tell us to use the matte black box instead of the aluminum grey box. ‘Nuff said.

Corollary to having a control expert choose the PCS: If you do not have the control expertise to choose a system on-site, rent it. Within your company there may be experts at other sites you can borrow. Control engineering firms can do system analysis and comparisons for you. This is money well spent given the size of the TIC.

7. How do I measure the performance of my system?

Look at your monthly production costs. Percent of loops on auto, integral of deviation of a variable from target, etc.: these all sound good on the surface. In many loops, they do help identify areas needing improvement. But the truth is far more elusive.

For example, choosing between two fuels means one will always be in manual (there goes the percentage of time on auto). Consider a surge tank on condensate return. Generally, boiler feed water is the most expensive water in the plant. Holding a perfect level is easy, and totally wrong (but it will have a good integral of deviation from target). High return flow dumps excess water to the sewer. Low return flow adds makeup water (from the anion and cation units and all the associated chemicals). What looks like good control is wasting many dollars. Why dump water for a short time and then immediately start to add makeup water? Let the tank level swing (within limits).

Automated "goodness of control" programs have the potential to mislead you in this case and in many more. Often those programs have a myriad of options to adapt to these issues, but do you really have the time to set up and maintain that complexity? Odds are you have not had the personnel to address your alarm management yet! Do put in one of these systems. They can pay for themselves with improved tuning. But then grab the 80% improvement pareto gives you (for a mere 20% of the effort) and move your resources onto another costly problem. Knowing how to interpret production costs will tell you if your control system is working well. When a cost per ton increases, look for the root cause; it may be a bad acting controller.

So there you have it: My version of seven simple things to share with noncontrol people (including computer geeks and process engineers working as control engineers). You may have several differences of opinion (leave your comments and examples below). Your list may differ a little or a lot from mine. That’s OK. Share this article with others in your company. If nothing else the article may serve as a catalyst to start a dialogue within your facility, and that can lead to improvement.

For those of you who have ever felt frustrated by any of these issues, just know I feel better having written this article.

Control Engineering invites you to write your version: www.controleng.com/contribute.

– Bruce Slade, PE, is the president/owner of Byte Size, a process automation and process safety consulting firm. Edited by Mark T. Hoske, content manager, CFE Media, Control Engineering, [email protected].

ONLINE

www.controleng.com/archives May under this headline find specific examples, and leave your comments.

www.controleng.com/contribute: to write your own advice.

Key concepts

- Control engineers offer talents, expertise, and perspectives that can save the plant a lot of money.

- Few in other areas of the plant understand the value of control engineering, and many can confuse it with other functions.

- Use this article as a catalyst to improve communication and optimization.

Consider this

What amazing things in your facility could get done if people understood the value of control engineers?

ONLINE extra

Bruce Slade, PE, is the president/owner of Byte Size, a process automation and process safety consulting firm, and a graduate of the U.S. Military Academy at West Point. A professional engineer, Slade has been involved in process automation for more than 35 years.

– See related articles below including an article posted in January 2015 about what control engineers should know about management.