Although proportional-integral-derivative controllers or “PID loops” have been the de facto standard of industrial feedback control for more than 65 years, they’re not always easy to use. For PID loops to perform up to their potential, they must first be tuned to fit each application, then periodically re-tuned to maintain the desired closed-loop behavior.

Sidebars: Adaptive control resource

Although proportional-integral-derivative controllers or “PID loops” have been the de facto standard of industrial feedback control for more than 65 years, they’re not always easy to use. For PID loops to perform up to their potential, they must first be tuned to fit each application, then periodically re-tuned to maintain the desired closed-loop behavior.

“Auto-tuning” controllers can help by automatically generating suitable tuning parameters upon request. With the control function disabled, the operator need only press the “tune” button and watch as the controller’s tuning function exercises the process until enough input/output data are available to quantify the process’s natural behavior.

A self-tuning controller includes a traditional PID control function as well as a self-tuning function that tries to maintain optimal closed-loop performance by continuously updating the controller’s P, I, and D tuning parameters. An auto-tuning controller is similar except that it performs its tuning operation justonce, then initiates closed-loop control using the parameters it has computed. Many commercial PIDcontrollers include both auto-tuning and self-tuning options, and many vendors use those two expressionsinterchangeably.

The tuning function can then recommend a set of P, I, and D tuning parameters that will produce the desired closed-loop behavior once the feedback control function is turned back on. Most auto-tuning techniques simply mimic the steps that an experienced control engineer would execute before bringing a loop on line for the first time. (See “Auto-Tuning Control Using Ziegler-Nichols,” Control Engineering , October 2006.)

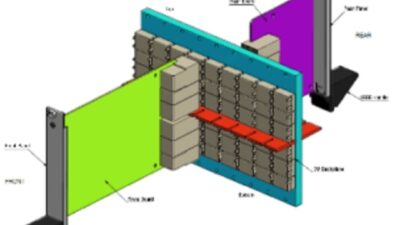

Continuous re-tuning or “self-tuning” is a more difficult challenge because the tuning and the control functions operate simultaneously. The controller must continue to maintain the process variable at a specified level as it tries to learn how the process variable reacts to control efforts. (See the “Basic self-tuning controller” graphic.)

Unfortunately, those are conflicting objectives. Maintaining a constant process variable deprives the tuning function of any useful insight into the behavior of the process, whereas exercising the process to see how it will react to a control effort defeats the purpose of the control function.

Fortunately, there are times during the normal course of closed-loop operation when the control effort and the process variable fluctuate anyway, and most self-tuners are designed to take advantage of those situations.

Setpoint tuning

A setpoint change provides an especially valuable demonstration of a process’s input/output behavior. Without taking the loop off-line, the self-tuning function can observe how the process variable reacts to each control effort as the control function attempts to achieve the new setpoint using its current tuning parameters. If that reaction proves to be too sluggish, the tuning function can substitute more aggressive tuning parameters or vice-versa.

One way to do so would be to treat the entire closed-loop system as a single process and the setpoint change as a step test that yields the overall gain and time constant(s) for the closed-loop system. The corresponding values for the open-loop process could then be derived from those results, and new tuning parameters could be computed using any number of traditional tuning rules. Yokogawa’s UT100 temperature controller employs a variation on this procedure that is based on the Ziegler-Nichols step response tuning rules. (See “Loop Tuning Fundamentals,” Control Engineering , July 2003.)

Unfortunately, setpoint changes tend to be rare in many process control applications where the controller’s objective is to maintain a given pressure, level, flow rate, or temperature at one specific value forever. Setpoint tuning is more useful in batch applications, such as multi-phase heating and cooling operations where setpoint changes are more frequent.

Disturbance tuning

Re-tuning a loop based on a process’s reaction to a disturbance is even trickier. The control effort and process variable do fluctuate as the control function attempts to compensate for the disturbance, but it isn’t always obvious whether the process variable is reacting to the control effort, additional disturbances, measurement noise, or a combination of all three effects. If the tuning function assumes that all process’ variable fluctuations are due to the control effort, then its understanding of the process behavior could end up skewed, and its revised tuning parameters could prove less than optimal.

The easiest fix to this problem is to require operator supervision of the tuning function. Upon observing additional disturbances after the re-tuning has begun, the operator could abort the tuning operation and wait for another solitary disturbance to come along. However, requiring operator intervention defeats one of the main purposes of an otherwise autonomous self-tuning controller.

One way to eliminate the need for an operator’s judgment is to enable the tuning function only when the control effort and process variable have begun a “limit cycle” or “hunting.” A limit cycle occurs when overly aggressive tuning causes the control function to over-react to an error between the process variable and setpoint. The resulting control effort is so large that it drives the process variable past the setpoint, resulting in a new error just as large as the original but in the opposite direction. The control function then reverses course and repeats the mistake ad infinitum , causing a series of sustained oscillations.

Not only is a limit cycle an easily detected indication that re-tuning is required, it gives the tuning function plenty of input / output data to work with when computing an improved set of tuning parameters. The UT100 offers this option as well, using tried-and-true Ziegler-Nichols ultimate sensitivity method (see “Loop Tuning Fundamentals” above). The SA and CB series of digital temperature controllers from RKC Instruments, the E5 series of process controllers from Omron Electronics, and the GFX4/GFXTERMO4 power controllers from Gefran also use limit cycles for on-the-fly loop tuning. (See the “Limit cycle tuning” graphic.)

Some self-tuning controllers wait for a limit cycle to occur before attempting to re-tune the loop. The current tuning parameters and the period of the limit cycle (Tu) are allthat’s needed to re-tune the loop by the Ziegler-Nichols ultimate sensitivity method.

Alternative techniques

However, a self-tuning controller that waits for a limit cycle to occur before initiating a remedial re-tuning operation will cause much more variability than some processes can tolerate and allow poor tuning to go uncorrected for extended periods. The self-tuning function might also have trouble distinguishing between actual limit cycles and periodic oscillations due to inter-loop coupling, deadband in a control valve, or cyclical disturbances.

A more sophisticated alternative is to look for clues about the process’s behavior in all of the input/output data, not just purely sinusoidal limit cycles. The gammadue Series X5 process controller from Ascon Corp. (also private-labeled as the Platinum Series of process controllers from Athena Controls) does so by analyzing the control effort and process variable in the frequency domain after each disturbance.

InSight, the self-tuning function available for the DeltaV automation system from Emerson Process Management, creates a mathematical model of the input / output data from which appropriate tuning parameters can be derived via IMC (internal model-based control) or Lambda tuning rules. It then indicates how well it understands the behavior of the process based on how well the most recent input / output data fits the current model. A tighter fit means a more accurate model and more reliable tuning parameters.

InSight also uses its process models to generate a “tuning index” that shows the expected percent change in variability that the new tuning parameters will achieve once implemented. The tuning index can also indicate which loops need retuning.

Automatic, but not simple

Not surprisingly, most vendors of self-tuning technology hesitate to reveal exactly how they achieve all these features and functions. And though the basic PID control algorithm is widely known, the mechanisms by which a particular self-tuning controller analyzes the available input/output data and generates tuning parameters are generally too complex to explain anyway.

That can be a problem for the plant engineer who is faced with the possibility of entrusting control of his process to a mysterious black box. It’s not possible to ascertain in advance whether the specific self-tuning technology under consideration will actually work for a particular application. Case histories can help establish credibility for a given manufacturer’s strategy, but performance cannot be guaranteed.

The uncertainties of self-tuning technology become particularly evident when the self-tuning function generates each new set of tuning parameters. Unless an operator reviews results before they are implemented or the self-tuning function somehow knows whether or not it has generated a reliable answer, there may be times when new tuning parameters make the loop’s subsequent performance worse, not better.

Benefits

Ironically, poor performance of the control function often leads to more dramatic fluctuations in the control effort and process variable, which in turn gives the tuning function much more useful information to work with. Still, it is helpful if the tuning function can recognize problems and flag questionable results. A Honeywell Universal Digital Controller equipped with the Accutune III algorithm knows when it has computed P, I, and D parameters that aren’t realistic and so informs the operator.

Even though self-tuning technology has yet to be perfected, its benefits can be worth the risks. A process that demonstrates time-varying behavior due to long-term effects, such as equipment wear or fluctuations in ambient conditions, can be difficult to control with a fixed set of tuning parameters. A self-tuning controller can track the process’s changing gains and time constants and adapt its tuning to match.

Even a stationary process can demonstrate variable gains and time constants if it is sufficiently non-linear. Controlling pH, for example, requires more conservative control efforts near the equivalence point. A self-tuning controller that can detect the increased gain of the process as the batch is close to being neutralized can throttle back its own tuning accordingly.

For more examples of self-tuning controllers in action, see part 2 of this article in August 2007.

Author Information

Vance VanDoren is consulting editor to Control Engineering. Reach him at [email protected] .

Adaptive control resource

Control Engineering , October 2002 or “Techniques for Adaptive Control,” available from the Resource Center at