Why is it important in the United States to identify machine safety standards for your business? See 6 ways standards help with machine safety.

Why is it important in the United States to identify machine safety standards for your business?

I hear this question often, asked by company representatives within the U.S. or by internationally based representatives who might not fully understand U.S. machine safety compliance methodology. Without time for a full seminar response, I try to keep my answer to 15 minutes or less. Some highlights follow.

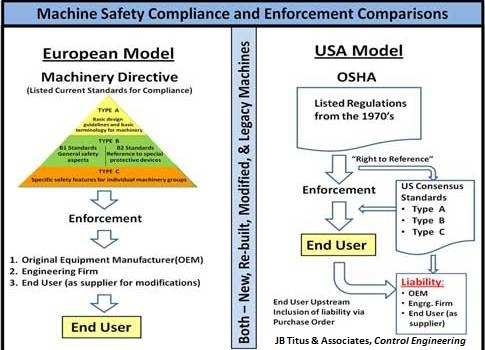

Understand that, unlike the EU for example, the U.S. does not have a Machinery Directive type of approach with listed standards called out in a regulatory manner mandating compliance. Compliance in the EU Machinery Directive approach is often considered a legal requirement because it takes consensus (voluntary) standards and makes them mandatory or legally binding. In so doing, a governmental body is laying out the legal compliance requirements and is establishing the high water mark for safety compliance across industry.

In the United States, safety experts mostly agree that the U.S. takes a different approach for machine safety. OSHA is considered the legal governing body of the U.S. government, and OSHA self declares that its regulations for machine safety are the minimums (low water mark) for safety compliance across industry. Therefore, the consensus standards are predominately voluntary across industry as additional measures for higher levels of machine safety. This picture sometimes is unclear because OSHA on occasion will reference a consensus standard, which then implies a legal requirement for compliance in addition to OSHA regulations. Sometimes this picture is further complicated by the U.S. court system because consensus standards can be used by lawyers to indicate a known safety measure for the purpose of assessing a liability.

Therefore, many safety experts will advise that businesses select machine safety standards for a variety of reasons, such as:

- Establishing a safer machine guarding environment, in addition to the OSHA regulations.

- As a means of meeting or exceeding environment health and safety (EH&S) established goals.

- To improve a company’s employee moral level by reducing the incidence of injuries.

- To achieve a best-in-class attitude and culture within a company.

- To improve bottom line performance (the cost of injuries goes directly to the bottom line).

- Because it’s good business practice.

…and more.

As you can see, quite often the answer to this question requires more than 15 minutes. Any questions? Post them below, and we’ll see if we can answer in future posts.

Browse other Machine Safety Blog posts.

Search related terms at Home. Or see related topics linked at the bottom of this post.

Contact: https://www.jbtitus.com for “Solutions for Machine Safety.”