Nervous about how artificial intelligence is integrating people, industrial automation and manufacturing operations? Here’s what I’ve heard lately about AI, including at Automation Fair.

Learning Objectives

- Understand that artificial intelligence and other tools for industrial automation serve people, not the other way around, according to leaders at Rockwell Automation.

- Explore how generative AI is already applied in Microsoft to help with writing code and how Rockwell automation is beta-testing generative AI use for its next-generation automation software.

- Review why Control Engineering subscribers think AI is important for industrial automation.

Artificial intelligence (AI) insights

- AI fosters synergy between human imagination and technology, driving resilience, agility, and sustainability in manufacturing automation.

- Generative AI empowers faster, more efficient code creation, enhancing automation system design and troubleshooting without compromising security.

How’s artificial intelligence changing how people integrate industrial automation and controls in manufacturing automation? It’s another tool to help people more quickly and effectively automate, optimize operations and solve big challenges, such as meeting sustainability targets. Will what I’ve heard lately below help you think again about how you’re integrating AI into manufacturing operations and other automation applications?

AI in industrial automation serves people, not the other way around

Future success is about connecting the imaginations of people with the potential of technology, according to Blake Moret, chairman and CEO of Rockwell Automation. “We want to combine the technology and expertise to create outcomes to help customers be more resilient, agile and sustainable,” he said.

Cyril Perducat, Rockwell Automation senior vice president and chief technology officer, explained that it’s not just about technologies, but creating the right experiences with technologies. There’s no way to invent the future without involving people and making technology usable. The world is changing to meet supply chain demands, resource and sustainability needs, resiliency requirements, as well as people and workforce considerations, he said.

Generative AI applied in next-generation automation

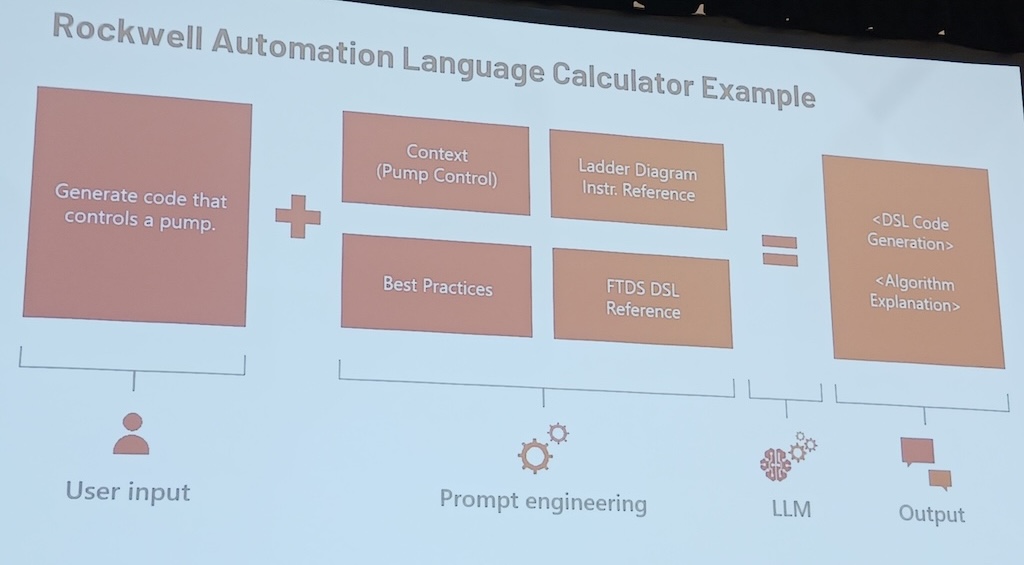

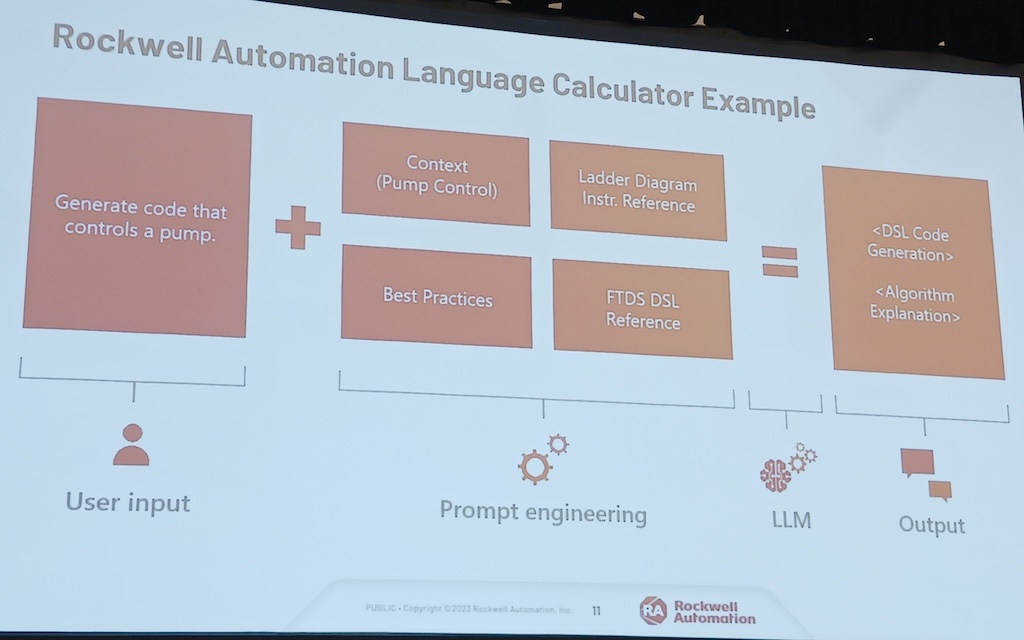

While AI dates back to the 1950s, new applications are emerging daily. An Automation Fair session called, “Harnessing AI for automation system design and troubleshooting,” Rockwell Automation said it is beta testing generative AI (spoken-word instructions) to generate sample code in the next version of Rockwell Automation’s FactoryTalk Design Studio. Citing customer security concerns, the AI prompts from customers will not be used to train the model.

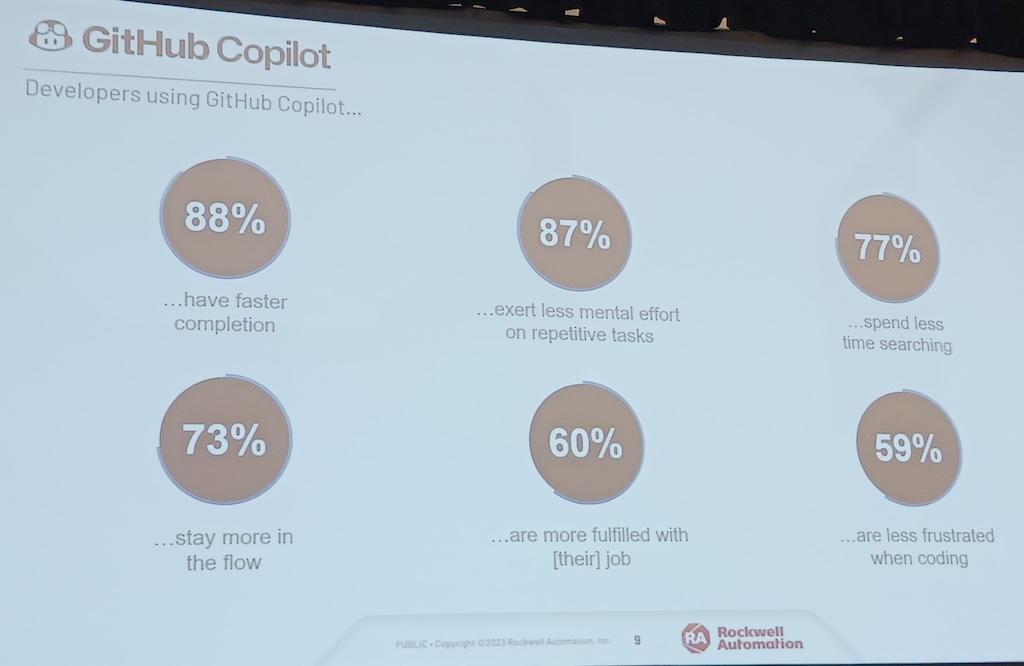

The AI feature is expected to be included in an upcoming version of the software at no extra cost, said Adam Gregory, platform manager, and Tony Carrara, business manager, both for FactoryTalk Design Studio, Rockwell Automation. Nick Kwiecien, data and AI cloud senior solution architect manufacturing for Microsoft, affirmed the value of generative AI integration, saying that when Microsoft used AI in its GitHub Copilot, 88% of developers using it reported faster code was completion, 87% spent less mental effort on repetitive tasks and 60% said they were more fulfilled in their jobs.

Why AI is important for industrial automation

As Control Engineering noted in October, citing its own “Artificial Intelligence in Industrial Automation” research, “When asked what factors are considered when deciding whether or not to implement AI-based automation solutions in industrial processes, the leading responses were: Operational efficiency gains; cost and return on investment (ROI); and availability and quality of data. Other important factors (about half or more of respondents also checked off) technological infrastructure as well as workforce impact and skill requirements.”

How are you applying AI to help automation, controls and instrumentation implementations?

Mark T. Hoske is content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: Artificial intelligence in industrial automation

CONSIDER THIS

Are you increasing your job satisfaction with AI?