Calculating an organization’s readiness for net zero carbon emissions can help identify what needs to improve. Sensors, energy management software and system integration and analytics can help, according to experts at Automation Fair 2023 by Rockwell Automation.

Learning Objectives

- Understand how energy management challenges include cost, security and sustainability, though an upgraded energy management calculator can help.

- Learn about how energy and emission savings potential for industrial sustainability need to be identified to produce successful use cases.

- Review training and new technologies Rockwell Automation offers with its partners at Automation Fair in Boston, Nov. 6-9, 2023, including in sustainability.

Rockwell Automation Fair sustainability insights

- Energy management challenges include cost, security and sustainability, though an upgraded energy management calculator can help.

- Energy and emission savings potential for industrial sustainability need to be identified to produce successful use cases.

- Rockwell Automation offers training and new technologies with its partners at Automation Fair in Boston, Nov. 6-9, 2023, including in sustainability.

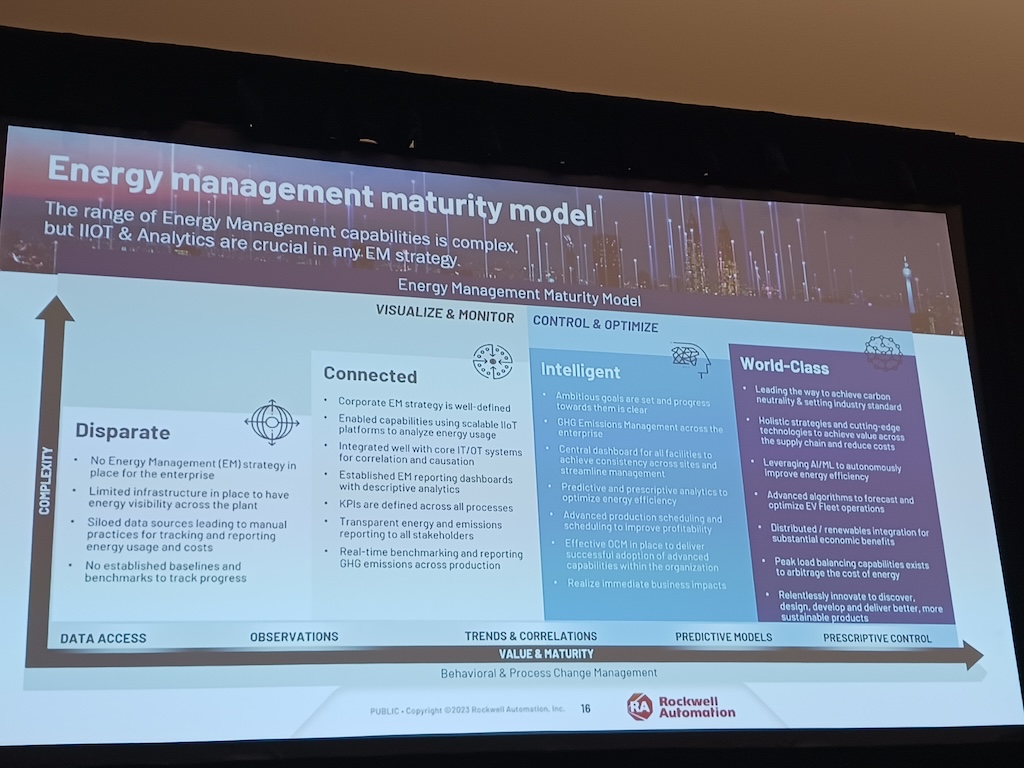

Maturity level is often applied in technology adoption applications, and four energy readiness maturity levels were offered to manufacturers and facility engineers Nov. 8, at Automation Fair 2023 by Rockwell Automation in the session “Discovering what’s possible: Calculating your energy readiness for net zero.”

Sinethemba Zulu, sustainability technology architect, Rockwell Automation, and Alex West, senior principal analyst, Omdia, discussed measurements and tools, challenges and successes related to industrial sustainability efforts.

Energy management challenges include cost, security and sustainability

They cited many motivators for energy management related to the energy “trilemma” of cost, security and sustainability. An industrial power outage can cost millions of dollars per hour, depending on the application, proven by recent climate concerns linked to wildfire expansion of intensity and frequency, and by rolling blackouts required to maintain grid balance during extreme weather events. Industries need regular, reliable access to energy.

Zulu said common challenges customers mention about sustainability efforts include regulatory reporting and compliance; achieving net zero and environment, social and governance (ESG) criteria; water stewardship; and material efficiency and circularity. He added that energy accounts for at least 5% of an average manufacturing company’s cost, and energy saving measures could save 10% to 30% of energy costs. Rockwell Automation products and service brands that can help include Allen-Bradley, FactoryTalk, Lifecycle IQ Services, Maverick Technologies, Kalypso, Fiix and Plex, Zulu said.

West, citing research on energy, ESG and the economy, said 39% of companies have energy accounting for greater than 15% of their costs and 69% of energy reduction efforts are strongly influenced by ESG efforts and goals. Significantly, a year after setting sustainability targets, more companies are behind than ahead on emissions targets and transitions to renewable energy sources.

Energy management challenges include cost, security and sustainability

An upgraded energy management calculator was mentioned as a resource.

Looking at maturity level of industrial sustainability efforts, 7% are in stage 1, where they use energy management software (EMS) but are not integrated; 21% are in stage 2, where they’re evaluating EMS integration, 51% are in state 3 with partially integrated EMS; and 21% are in stage 4 with EMS fully integrated with other plant or factory software tools.

West passed along the observation that oil has to be refined to gasoline to make internal combustion engines run, and data has to be refined into information to make effective decisions.

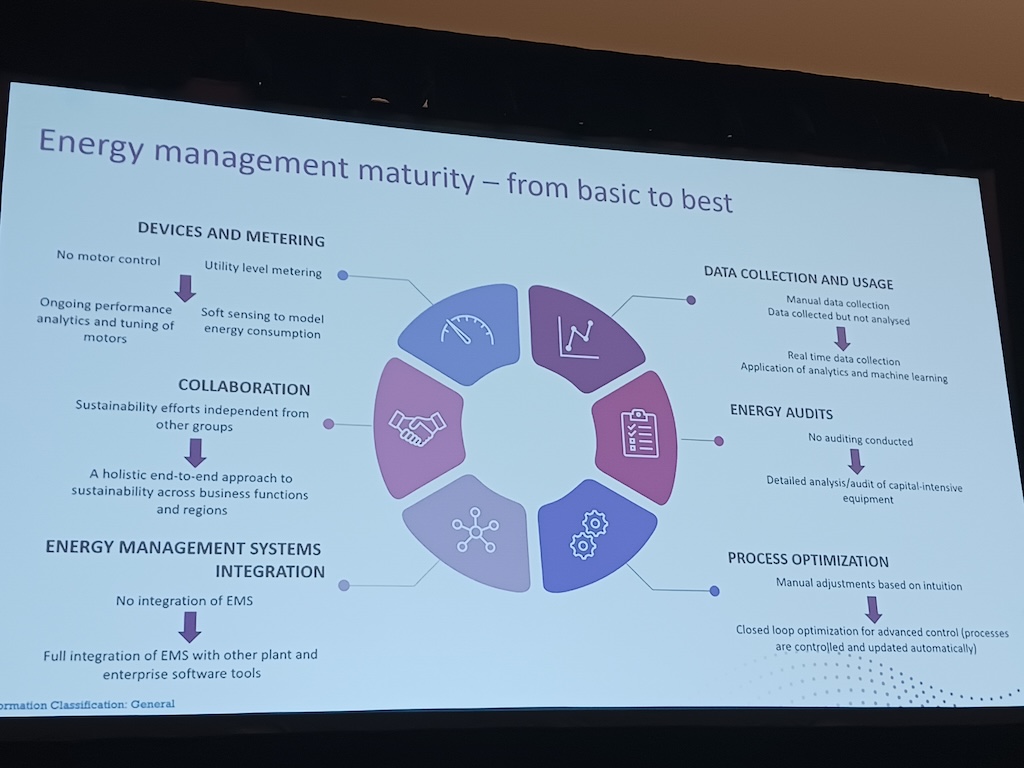

Looking at energy management maturity, devices and metering are most basic, followed by collaboration, EMS integration, data collection and use, energy audits and process optimization at best.

By 2025 many companies will need to report and demonstrate progress toward targets and tools such as machine learning and analytics and advanced process control solutions can help.

In addition, there’s a shortage of green skills sets, required to help, including auditing and monitoring, reporting, lifecycle assessment, regulatory compliance, operational improvement and energy management.

Energy and emission savings potential for industrial sustainability

Zulu outlined energy and emission savings potential in:

-

Modern energy management systems

-

Energy, production and emissions data integrated

-

Production scheduling drive by energy insight

-

Predictive and prescriptive analytics

-

Artificial intelligence (AI), machine learning (ML) and closed-loop application

-

Demand management via ML

-

Distributed energy resources dispatch

-

Renewable and cogeneration integration.

Sustainability case studies in water/wastewater and mining

Two sustainability applications, water and wastewater and mining, were discussed.

In water and wastewater industry the Eastern municipal water district (EMWD) cited 2,200 kWh savings per day. Less energy use and less chemical use totaled more than $100,000 savings per month.

AI used machine learning to adjust proportional-integral-derivative (PID) coefficients and improve dissolved output (DO) setpoint tracking.

In a Sibanye Stillwater mining ventilation application, Energy Drive Co. installed optimized variable-speed drives (VSD) to optimize fans. Previously, the application ran one fan at a time. With VSDs applied, fans both could operate at the same (lower) flow rate with greater energy efficiency. Energy saved in first shaft was 62% with 48% saved in the second with 379,000 tons of annual carbon savings.

In a separate tour of the Automation Fair sustainability booth, Zulu discussed several other applications, including a new vertical farming partnership installation underway at the corporate Rockwell Automation office in Milwaukee, called ClockTower Farms, expected to grow 150 tons of produce a year.

Mark T. Hoske is content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS

Automation Fair, Rockwell Automation

CONSIDER THIS

Is your industrial sustainability measuring, integrating and controlling as needed to exceed stated sustainability goals? If not, how can automation expertise help?