Benefits of SDRs for IIoT device testing

Software-defined radio (SDR) systems are suitable for implementing testing and measurement of Industrial Internet of Things (IIoT) devices.

Learning Objectives

- Software-defined ratio (SDR) systems use software-based components instead of traditional hardwired components.

- SDRs can help make Industrial Internet of Things (IIoT) systems more flexible.

- The reconfigurability of SDR platforms allows new IIoT protocols and algorithms to be implemented by changing the software.

Software-defined ratio (SDR) insights

- Software-defined ratio (SDR) software uses software-based components instead of hardwired components, which gives them more flexibility in industrial environments.

- Using software-based components in SDRs allows the realization of multi-purpose and easy-to-upgrade testing solutions by configuration via the host system API. This is helpful in wireless Industrial Internet of Things (IIoT) devices and other applications.

Traditional industries use wired communication infrastructure and systems to connect various devices. Wired systems are rigid, and the cost of installing and maintaining them is usually high. These downsides have led many industries to switching to wireless Industrial Internet of Things (IIoT) systems which require testing solutions that are more flexible and versatile. Software-defined radio (SDR) systems are suitable for implementing testing and measurement of IIoT devices. An SDR is a flexible radio communication system that uses software-based components instead of traditional hardwired components.

IIoT systems

The domination of wired communication infrastructure in industrial environments is slowly ending as there’s been a transition to wireless systems. The IIoT paradigm replaces wired systems with more flexible wireless systems capable of interconnecting various devices, ranging from factory floor sensors to automated inventory and transport systems.

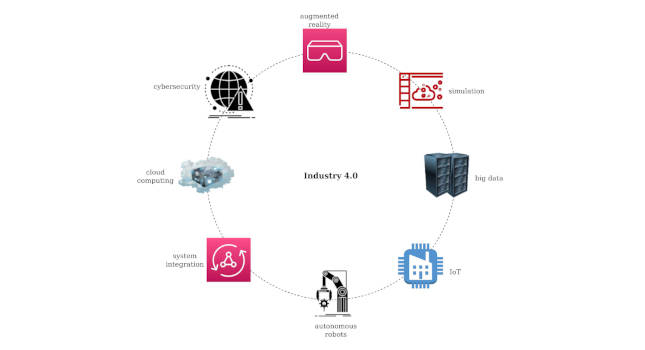

The Internet of Things (IoT) is one of the enabling technologies of Industry 4.0, an industrial revolution using data acquired from smart sensors to realize automated and data-driven assembly and production (Figure 1). Compared to traditional wired systems, wireless IIoT systems allow quick reconfigurability and can enhance the overall productivity of an industry. They also are are cheaper to install, maintain and scale.

Figure 1: Enabling technologies of Industry 4.0 include IoT, cloud computing, augmented reality, simulation and system integration. Courtesy: Per Vices

The IoT’s rapid growth has accelerated the adoption of wireless sensor networks (WSNs) in industrial environments. These networks are used for many applications such as telecommunication, remote control, environment monitoring and disaster detection. WSNs connect a wide variety of small sensor elements that gather data and transmit it to the access points, which is later processed to generate meaningful and actionable output.

Replacing industrial wired systems with IIoT systems entails designing and deploying hybrid wireless sensor networks. These networks connect sensing devices that gather data required to realize automated and artificial intelligence (AI)-driven industrial processes. The process also involves integrating the sensor networks with existing infrastructure to allow wireless communication between a variety of industrial devices, including actuators, sensors and programmable logic controllers (PLCs).

IIoT devices used in today’s industries use a wide range of non-interoperable wireless standards and protocols, including Wi-Fi, Long Range (LoRa), 2G, 3G, LTE MTC Cat M1, ZigBee, Bluetooth Low Energy (BLE), Ingenu, NB-IoT, WirelessHART and weightless. Specifications for low-energy critical infrastructure monitoring (LECIM) networks are defined in the IEEE 802.15.4k standard, which also defines physical and multiple media access (MAC) layer protocols.

The number of IoT devices that use machine learning (ML) and AI also is growing rapidly. This trend is expected to continue with the growing demand for fully autonomous industrial systems. AI and ML allow systems to perform complex tasks without requiring human intervention and are expected to reduce human error.

Replacing traditional wired communication infrastructure with wireless IIoT solutions has many benefits. Apart from reducing the overall cost of installation and maintenance and simplifying configuration, IIoT systems also enhance the mobility of industrial systems. It is very important to test many IoT devices to ensure proper connectivity and operation, especially when operating on a very large scale.

IIoT device testing challenges

The diversity of standards and protocols used in the IIoT ecosystem presents a big challenge to test and measurement (T&M) engineers, as the pace at which these protocols and standards evolve far exceeds the pace at which test solutions are updated, often leaving engineers with limited means to test some IIoT devices. Furthermore, this challenge also increases the overall cost of procuring solutions for use in automated testing.

Testing IIoT devices often involves employing different solutions to test various elements of a device, such as security, performance, connectivity, and compatibility. Since most systems contain many devices, manual testing consumes excess time and effort. Therefore, automated testing processes have been implemented, as they enhance overall efficiency and boost productivity.

These challenges make testing IIoT devices using traditional equipment costly and time-consuming. The task demands robust, versatile and flexible solutions. SDR platforms offer performance characteristics suitable for implementing flexible testing solutions for IIoT devices.

SDR system elements and benefits

Some of the elements implemented in an SDR include filters, modulators, mixers and detectors. Unlike hardwired components that become obsolete after a certain time, software-based components are reconfigurable, can be upgraded. High-performance SDR platforms offer a high bandwidth, wide tuning range, and multiple-input multiple-output (MIMO) capability, which is important when dealing with tests that require different frequencies. Figure 2 shows the main parts of a typical SDR system.

Figure 2: Overview of an SDR system includes a radio front end, analog to digital and digital to analog converters (ADC/DAC) and a digital backend, often a field-programmable gate array (FPGA) connecting to a host system. Courtesy: Per Vices

A typical SDR system features transmit and receive functions and contains multiple independent channels that are controlled in software. These radio channels have dedicated analog-to-digital converters (ADCs) and digital-to-analog converters (DACs), which can be used for implementing different testing functions. In addition, high-performance SDRs offer a very wide tuning range and a high instantaneous bandwidth, typically 1 to 3 GHz.

The backend of most high-performance SDR systems features a field programmable gate array (FPGA). These FPGAs offer various onboard digital signal processing (DSP) capabilities and allow the implementation of custom DSP solutions and utilization of IP cores.

SDRs for testing IIoT devices

SDR platforms have capabilities that make them ideal for various T&M applications in today’s industries. Using software-based components in SDRs allows the realization of multi-purpose and easy-to-upgrade testing solutions by configuration via the host system API. SDR-based solutions also offer enhanced flexibility and capability compared to conventional test solutions.

Most conventional test solutions are specialized and cannot be used for more than one function. For instance, separate tools are required for testing the security, performance, and protocols of one device. SDR platforms allow one piece of equipment to be used for many purposes, either independently or in tandem with other SDR-based solutions. In addition, unlike conventional T&M solutions, various aspects of an SDR-based solution such as processing requirements, software requirements and interface can be customized.

A wide variety of waveforms and transmission schemes are used in today’s IIoT ecosystem, demanding an adaptable testing solution. The reconfigurability of SDR platforms allows them to support a broad spectrum of waveforms and transmission schemes. SDRs also offer multiple MIMO (multiple in, multiple out) channels that can be used for transmitting or receiving functions. MIMO SDR platforms are suitable for implementing T&M solutions capable of performing tests at different operating frequencies over various antenna systems.

The IIoT ecosystem changes and requires test solutions that are easy to update. The reconfigurability of SDR platforms allows new protocols and algorithms to be implemented by changing the software. Moreover, the reconfigurability of these platforms enables the implementation of test solutions capable of accommodating changing test conditions. For instance, by performing processing on data that is to be transmitted, noisy environments, interference or other transmission impairments can be simulated to see how robust the receiver is.

The software controllability of SDR platforms allows the implementation of advanced stand-alone solutions suitable for performing end-to-end testing. This capability means tests can be performed on a device under test (DUT) without requiring additional equipment. SDR-based solutions also allow tests to be done without human intervention. Such automated tests have minimal human-related errors and yield high reliability and consistency.

SDR platforms support a broad array of open-source development toolkits, such as GNU radio, and offer the ability to develop custom programs based on the UHD API. This property enables the implementation of testing solutions for a wide range of applications, including network testing, device testing, and simulation. SDR-based solutions also can integrate into existing lab servers for remote access by T&M engineers, allowing for collaboration across the globe.

Additional benefits stem from the SDR’s advanced networking capabilities. Most conventional testing solutions have limited storage capacity and cannot store huge amounts of data. In comparison, the highest throughput SDR platforms feature high performance network interfaces that allow them to transfer vast amounts of data to a host or storage system. This allows for the real time transfer of information for further analysis, and room to capture more parameters.

Optimizing industrial wireless applications

As with any new technological progression, extensive testing must be done to ensure wireless communications work as planned since so many processes and businesses dependent on constant functionality. Current challenges include the diversity of protocols used in the IIoT ecosystem, which makes it difficult to perform automated testing with traditional T&M equipment.

Because many tests are required, scalability and rapidly advancing technology make regular T&M impractical and obsolete. Software defined radios are now being integrated into testing solutions due to their advanced capabilities that offer flexible and reliable solutions to many of the current problems plaguing the testing of IIoT devices. Compared to conventional equipment, SDR-based solutions are easier to install, maintain, upgrade, and scale, and offer a wide tuning range, high instantaneous bandwidth, MIMO channels, and FPGA resources, which is integral in high performance testing scenarios.

Brendon McHugh is a field application engineer and technical writer; Simon Ndiritu is an electrical engineer and technical writer at Per Vices. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, cvavra@cfemedia.com.

MORE ANSWERS

Keywords: software-defined ratio (SDR), SDR, Industrial Internet of Things (IIoT)

CONSIDER THIS

What tools are you using to improve your wireless networking implementations?

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.