The factory floor is the heart of any manufacturing enterprise. At times, however, manufacturing executives seemed more concerned with perfecting processes for designing and delivering products, with the production almost an afterthought. If manufacturers ever did view the building of products as somehow less important than other aspects of the business, that attitude certainly has changed.

Process plants are turning operational data into strategic weapons.

The factory floor is the heart of any manufacturing enterprise. At times, however, manufacturing executives seemed more concerned with perfecting processes for designing and delivering products, with the production almost an afterthought.

If manufacturers ever did view the building of products as somehow less important than other aspects of the business, that attitude certainly has changed. As competition has become increasingly global—and much more intense—there’s a growing emphasis on making sure all products are built right the first time.

Giving manufacturers the ability to ensure that products are meeting quality standards before they leave the factory is a major focus for several companies in the Business Process Management category of the 2009 Manufacturing Business Technology Emerging 40 Software Vendors list.

Several of these companies were launched around products that focus on specific aspects of production, such as manufacturing execution systems (MES). Examples include Performix, which offers a suite of solutions for managing shop-floor processes, or Preactor, which sells software for developing optimal production schedules.

As the business landscape has changed, however, these companies have adapted. They still perform their original functions well, but now these vendors are also dedicated to making sure information about the processes they manage can be easily fed to higher-level systems in order to help improve the performance of entire enterprises and supply chains.

For instance, Performix, which built its xMES suite of applications to control batch production processes such as recipe management, now uses the SAP Manufacturing Integration and Intelligence (MII) platform to build composite applications that allow for passing data back and forth between various modules of the SAP ERP system and the xMES suite. Data coming from SAP, such as incoming orders, helps with scheduling production assets, while information going from xMES to SAP—such as equipment status and product quality—helps with keeping customers informed about when they can expect orders to be delivered.

The latest version of the advanced planning and schedule system from Preactor contains a windowing feature that can display information from other applications. Preactor reports significant customer interest in the work it has done to make this feature work smoothly with Wonderware MES systems. With this link, clicking an icon representing a specific production machine displays overall equipment effectiveness data on the machine contained in the Wonderware system. Preactor also has taken advantage of an integrated messaging system to create a method for the MES system to send production schedulers real-time updates on equipment breakdowns.

The use of composite applications to improve business performance is not limited to plant floor processes.

QlikTech, supplier of a new generation of business intelligence technology, is helping manufacturers use the data stored in existing business systems to create new, strategic applications.

Seco Tools, a worldwide supplier of cutting tools, has developed roughly 150 different applications on the QlikView business intelligence platform from QlikTech, including one that allows Seco to use pricing strategies to help maintain its exceptional 24.7 percent profit margin.

The following pages mention more vendors helping manufacturers turn operational data into strategic weapons.

Business process management emerging software vendors list

Acsis , www.acsisinc.com

Flagship product : Acsis Manufacturing Application Platform, a suite of solutions for optimizing business processes.

Most recent upgrade : Manufacturing Optimization Suite, a set of solutions to address optimization of shipping and receiving, manufacturing execution, warehouse management, and supplier management.

Major business problems addressed : Streamlining execution of business processes, minimizing labor costs, reducing errors, improving data accuracy.

Factors driving growth : The ability to identify the value Acsis solutions will bring to business prior to implementation.

Specific customer benefits : International Gaming Technology, the world’s largest manufacturer of casino gaming machines, has linked the Acsis Manufacturing Execution solution to its SAP ERP suite, gaining real-time visibility into its processes.

alqemyiQ , www.kenosia.com

Flagship product : DataAlchemy, a platform for analyzing demand and sales data.

Most recent upgrade : DataAlchemy 6.2, includes a data import wizard and a tool for automating the process of upgrading the report viewer.

Major business problems addressed : Problems associated with data management, including the time spent creating reports, updating reports, and sorting through reports from multiple sources.

Factors driving growth : New product features, and a new subscription pricing model.

Specific customer benefits : At Heineken USA, DataAlchemy is used to automate business review for field sales teams. “By using DataAlchemy, our team can easily customize the reports for the specific markets and time periods they need,” says Larry Gray, senior category manager, Heineken USA. “We have reduced the amount of update time by roughly 70 percent compared to the manual process.”

Knoa Software , www.knoa.com

Flagship product : End-User Management Solutions, a suite of applications for monitoring, measuring, and managing how end-users actually use business applications to optimize business process execution.

Most recent upgrade : Knoa Virtual/Cloud Experience Manager, a solution that monitors and manages real end-user experience for enterprise applications that are running in virtualized environments, delivered via SaaS, or provisioned via cloud computing.

Major business problems addressed : Attacks the last barrier between the enterprise and the fully realized ROI from the investment in enterprise applications.

Factors driving growth : The need for companies to get the most value from IT investments.

Specific customer benefits : Using Knoa tools to monitor use of its SAP ERP system, Kimberly-Clark discovered that five specific transactions caused roughly 90 percent of all user errors. This led to changing annual user re-training sessions from week-long reviews to one-hour focused classes, saving nearly $395,000 per year.

Manuvis , www.manuvis.com

Flagship product : FactoryMRI, a manufacturing intelligence platform.

Most recent upgrade : A SaaS version of FactoryMRI, with energy management functionality.

Major business problems addressed : Providing real-time information on manufacturing operations, including equipment status, labor utilization, and other KPIs.

Factors driving growth : The desire to have executive-level awareness of production operations.

Specific customer benefits : One Manuvis customer uses the new energy management functionality in FactoryMRI to automate the creation of reports for EPA audits.

Network Automation , www.networkautomation.com

Flagship product : AutoMate, a platform for automating IT functions such as running batch reports or program scripts.

Most recent upgrade : AutoMate 7.1, includes a task builder feature that allows for scheduling multiple jobs, a feature for performing tasks on multiple machines, and one that allows for setting triggers for jobs to process when certain conditions exist.

Major business problems addressed : Increasing the productivity of IT operations without increasing staff. Factors driving growth : Organizations’ heightened focus on reducing costs while increasing the role of IT to deliver value to business units.

Specific customer benefits : World Precision Instruments, a manufacturer of laboratory equipment, freed employees from have to log into the company’s VPN at night to run critical ERP reports by turning that process over to AutoMate.

Noetix , www.noetix.com

Flagship product : Noetix Views, a platform for building reports, primarily from data contained in an Oracle ERP suite.

Most recent upgrade : Noetix Analytics, a solution based on a data warehouse infrastructure that manages performance, scalability, and data integration requirements for customers using Oracle and non-Oracle applications.

Major business problems addressed : Translating complex data contained in business applications into easy to use reports, providing non-technical business professionals with the information they need to answer their own business questions without IT assistance.

Factors driving growth : The economic downturn is spurring organizations to examine the way they retain customers, spend capital and operating budgets, and comply with regulations.

Specific customer benefits : Elliot Turbo Company, a global leader in the design and manufacturing of technically advanced gas compressors and steam turbines, used the Noetix platform to create an intranet site that is a combination of Web-page information and static reports originating from the company’s ERP system, PLM System, and legacy systems so that users can access real-time and historical business information.

NuBridges , www.nubridges.com

Flagship product : NuBridges Exchange, a suite of applications for protecting information as it travels within and across enterprises.

Most recent upgrade : NuBridges Exchange 3.0

Major business problems addressed : Protecting stored data, and protecting data while it is transported internally and externally.

Factors driving growth : The desire by manufacturers and retailers to conduct business transactions and exchange documents securely while adding and managing domestic and international trading partners more easily.

Specific customer benefits : K’NEX Brands, a leading manufacturer of toy construction equipment, realized a huge cost savings from using NuBridges Exchange as its primary platform for exchanging AS2 documents with its large retail customers.

Performix , www.performixinc.com

Flagship product : Performix xMES, a suite of applications for managing and executing the manufacturing of batch processes including recipe management, manufacturing execution, and electronic batch records.

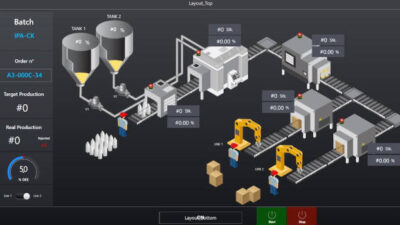

Most recent upgrade : Next Generation User Interface for plant floor operator execution. The new UI combines Rich Internet Application (RIA) technology with the flexibility to integrate data from existing business systems, plant floor devices, and the Performix xMES solution.

Major business problems addressed : Using SAP MII for integration to the SAP ERP suite, Performix xMES allows manufacturers to leverage existing data and functionality within their SAP system, deriving the most value from their current ERP and plant floor investments with minimal incremental costs.

Factors driving growth : Manufacturers desire to have real-time insight into manufacturing operations

Specific customer benefits : Leading chemical manufacturer Dow Corning used Performix xMES to create an electronic work instruction application that automates the flow of information from the company’s SAP ERP system to plant floor operators.

Preactor , www.preactor.com

Flagship product : Preactor, an advanced planning and scheduling solution.

Most recent upgrade : Preactor, Version 11 introduces new ease of use features as well as new tools for materials control, reporting, and integration that enables Preactor to access data from complementary applications.

Major business problems addressed : Helping manufacturers become more responsive to variable demand while reducing costs and increasing profitability.

Factors driving growth : An increasing awareness of the benefits that APS software brings either stand alone, or more often in conjunction with ERP, MES, and shop floor data collection solutions.

Specific customer benefits : U.S. Paint reduced work-in-process inventory by 50 percent and solved a perceived problem with production capacity after adopting the Preactor planning and scheduling solution.

QlikTech , www.qlikview.com

Flagship product : QlikView, a business intelligence platform.

Most recent upgrade : QlikView 9 features enhanced enterprise manageability, performance and scalability, real-time data, and reporting capabilities and can be deployed in the cloud.

Major business problems addressed : Lets any business user create his or her own analyses and adjust it on the fly to meet changing business needs—with no IT support.

Factors driving growth : A transparent business approach. Anyone can download QlikView free, using actual data to start building applications.

Specific customer benefits : WILO AG, a leading manufacturer of pumps and pump systems for heating, ventilation, and air conditioning technology, as well as for water supply and sewage disposal, has built more than 100 applications on the QlikView platform, including one that ensures it prices all products to achieve maximum profitability.

Rootstock Software , www.rootstocksoftware.com

Flagship product : Manufacturing Systems, a suite of solutions for managing production operations built on the Software-as-a-Service model.

Most recent upgrade : Rootstock MRP for NetSuite, a comprehensive solution for discrete manufacturing businesses and the first pure SaaS manufacturing resource planning (MRP) system built on and delivered via NetSuite’s SuiteCloud computing platform.

Major business problems addressed : Fast deployment of complete manufacturing solutions for discrete manufacturers

Factors driving growth : The need for low-cost, easy-to-deploy and manage software solutions.

Specific customer benefits : CertiCell, a leader in the repair and deployment of carrier-grade, premium-class mobile phones, PDAs, and smartphones, chose Rootstock’s integrated suite to support multiple manufacturing sites with one global manufacturing system.

Ultriva , www.ultriva.com

Flagship product : Lean Factory, a suite of applications to support Lean Manufacturing processes.

Most recent upgrade : Enhanced overall equipment effectiveness module.

Major business problems addressed : Helping manufacturers transition to Lean manufacturing

Factors driving growth : Growing interest in Lean techniques.

Specific customer benefits : Hussmann Corporation, an Ingersoll-Rand company, improved management of parts coming from outside suppliers by deploying Ultriva’s electronic kanban solution.

Verical , www.verical.com

Flagship product : Verical Marketplace, an online exchange for buying and selling electronic components

Most recent upgrade : Verical Marketplace launched in October 2009

Major business problems addressed : The need for finding new reliable suppliers of electronic components

Factors driving growth : Companies’ desire to find new suppliers and customers across the globe.

Visual Mining , www.visualmining.com

Flagship product : NetCharts, a suite of applications for managing and analyzing business data.

Most recent upgrade : NetCharts Performance Dashboards, a dynamic, interactive dashboard solution that empowers business users to analyze data, gain insight, and make better business decisions with very little assistance from the help desk or IT team.

Major business problems addressed : The need for non-technical users to analyze data quickly and easily improve business decision making.

Factors driving growth : Providing an intuitive, effective, affordable solution for accessing, and analyzing information.