Demand for electric power is growing around the planet. Emerging markets like China and India are going to dramatically influence global demand. Here in the U.S., rates are up. Power grids are becoming strained. Manufacturing processes and new electronic devices require more power. But companies can do a lot to control their energy destiny by understanding how important energy is in the overall...

Demand for electric power is growing around the planet. Emerging markets like China and India are going to dramatically influence global demand. Here in the U.S., rates are up. Power grids are becoming strained. Manufacturing processes and new electronic devices require more power. But companies can do a lot to control their energy destiny by understanding how important energy is in the overall success of their business.

No longer do companies have to passively view electricity as an unmanageable, fixed cost. With new tools and technology, manufacturers can reduce a million-dollar energy line item by 20%. The key is to monitor and analyze energy use so companies can predict needs and control excess use. That information can be used to help negotiate energy prices with suppliers based on supply and demand, guide predictive maintenance schedules to improve reliability, lower costs associated with the manufacturing process, as well as affect a host of other areas to improve the bottom line.

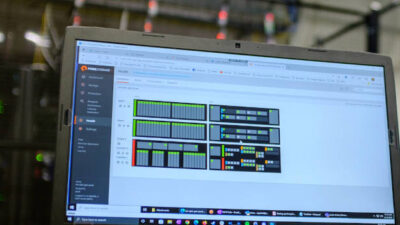

Schneider Electric worked with a Hershey Company manufacturing plant in Virginia which, after 20 years of growth, had reached its power capacity limit. The plant needed data to help gauge exactly how much the electrical infrastructure should be upgraded, so it installed an energy and power management system that accumulates and analyzes data on every device being used and constantly displays system status. Such exact usage information better tracks costs and helps forecast the additional power needed for growth.

Most manufacturing equipment and systems run on microprocessors. This digital technology cannot tolerate a power interruption of more than milliseconds. This is a major shift from our industrial past, when we defined a power outage as an interruption of five or more minutes. Although we can’t yet attain 100% uninterruptible power, there are systems that deliver 99.99999% reliability, which translates to an annual downtime of just seconds. By comparison, a 99% reliability of a power system translates to more than 3.5 days of downtime per year.

At Schneider, we like to say that we “eat our own food” by using our own energy management tools and services to increase energy efficiency in our North American organization. Energy can represent 50% of all production costs in an industrial facility, so this is a big issue for us.

In the mid-1990s, we selected five of our plants with the highest utility bills. After improvements using our Square D power monitors, were able to reduce energy consumption and lower other costs by 10% to 30%. Today, we continue to implement an energy efficient strategy. Our plants have undergone an in-depth energy analysis by our Industrial Energy Efficiency services team. As part of its Total Energy Control program, the team benchmarks energy usage and creates an action plan to prioritize energy and utilities cost savings projects. We installed building automation systems that allow us to monitor energy consumption remotely, and be alerted whenever a facility maintenance system has excessive energy use.

Last year, we had more than 7,000 energy efficient lighting fixtures manufactured by Juno Lighting Group installed at our sites. Because industrial motors can account for 60% of a plant’s electricity usage, we are constantly analyzing motor systems and identifying opportunities for improvement. We have seen a 10% to 20% reduction in energy consumption by adding variable frequency drives that match motor output to required loads. We are now seeing about $1 million in utility cost savings annually.

Energy affects every area of a business, from operations to finance, so it needs to be a factor in any business or strategic plan — just like research and development or quality control. Identify energy leaders in all plants and facilities, and set clear goals for energy management. Companies that adopt a philosophy that power can be controlled, managed and optimized will be able to turn a costly expense into a competitive advantage.

Author Information

David Petratis is president and CEO of the North American Operating Division of Schneider Electric, a US$23.7 billion global company with 120,000 employees and 205 manufacturing facilities around the world.