Organizations using Industry 4.0 with edge technologies gain benefits such as lower costs, faster speeds, easier troubleshooting and others.

Learning Objectives

- Gathering data at the edge is critical for companies looking to take advantage of Industry 4.0.

- Edge computing’s popularity is rising as technology gets cheaper and more accessible for users.

- Case studies on how edge computing information and data flow in multiple industries are highlighted.

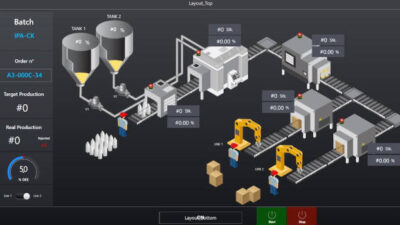

People and companies who want Industry 4.0 will find it at the edge. That’s what many experts say as edge computing continues to grow in popularity in a variety of industries. As a result, edge technologies are seen as a key element in creating Industry 4.0 solutions. Processing more data at the edge is bringing improved operational efficiency, better decision-making, lower costs and more.

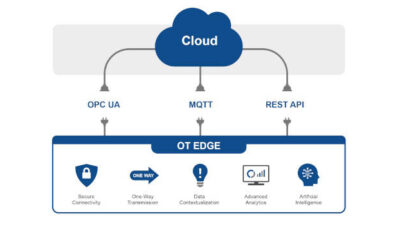

Edge technologies are computing devices and services being used at the edge of a network, where they’re close to the data being collected. With data being managed, analyzed, contextualized and cleaned near the source, it can move through the system in a more efficient manner – saving resources and costs as it goes. New edge devices may come with licensed supervisory control and data acquisition (SCADA) software and message queuing telemetry transport (MQTT) embedded, making it easy to collect and send more data from the edge.

“There are so many benefits from doing things at the edge,” said Travis Cox, co-director of sales engineering at Inductive Automation. “We have speed; we can access more data at faster rates. We have guaranteed local connectivity, and store-and-forward in case there are connectivity issues with the central system. Edge also helps us go to scale. We can do protocol conversion at the edge, and use some simple algorithms where we’re monitoring things, and when we see certain conditions, we can write information back to the programmable logic controller (PLC). We can leverage machine learning (ML) and build models that can make decisions on the fly, right there at the edge. For example, we could predict failures or tune the process. There are a lot of possibilities.”

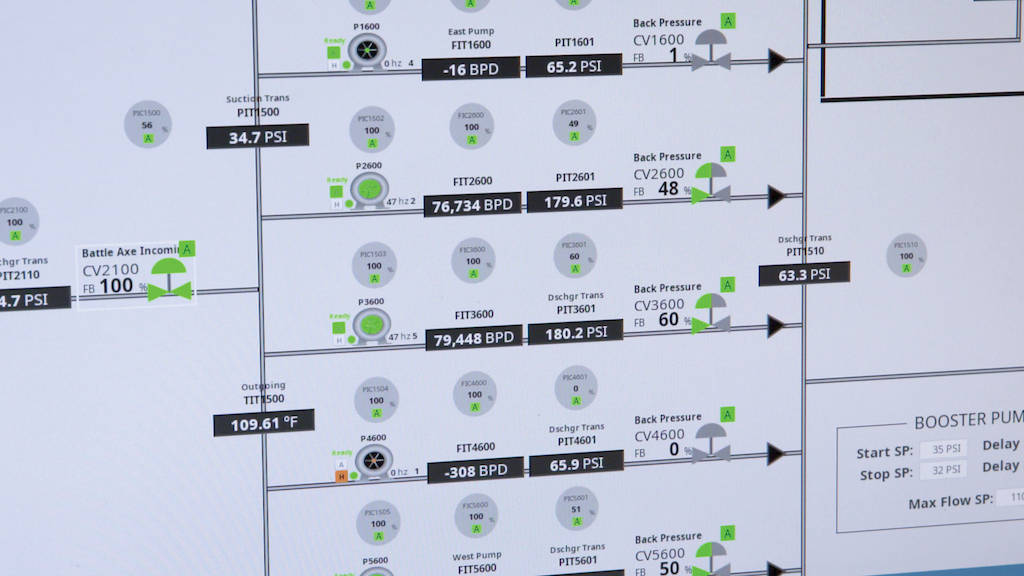

Edge computing brings better monitoring of equipment and greater flexibility in the architecture. It can provide alerts before equipment fails, improve security and be easier to manage and maintain. It also can be the basis of a more automated and efficient system that responds faster to business needs. Edge technology can send data all the way up to the cloud, where it can be fed into deeper analytics, ML and artificial intelligence (AI).

“I don’t think you could really do Industry 4.0 without edge computing,” said Alex Marcy, president of Corso Systems, a system integration company that works in a variety of industries. “Edge computing increases robustness of the system. And digital transformation is easier to do with edge computing because of the ease of deployment.” Marcy cited low-cost hardware, more efficient communications, and increased flexibility as being key parts of the edge’s impact on Industry 4.0.

Lower costs, faster starts with edge computing

Edge computing’s rise is thanks to today’s more powerful computers and lower overall costs.

“Before, it was very cost-prohibitive to put a bunch of edge computers out there, that were powerful enough, that were fan-less and rugged and all that,” Cox said. “It was expensive back then. Today, with computers being a lot cheaper, people can get high-end, more powerful computers, and embedded computers, that they can put out there, especially if they’re buying at scale. They can get it very cost-effectively.”

Cox said managing edge technologies is a must, but that is easier today than in past years. “There are a lot more orchestration platforms,” he said. “We’re looking at leveraging containers, like Docker in particular, where there are management facilities, where we can do fleet management, for example. Because the computing costs have gone down, and because of these management tools, it’s much more effective to do it today than it was 10 years ago.”

There are several other factors working in favor of edge computing when it comes to lower costs. “It’s a variety of ways,” said Brian McClain, business development manager for Corso Systems. “Part of it is your hardware in the technology stack itself. Traditionally within a manufacturing facility that’s operating in traditional proprietary operational technology (OT) systems, those systems require a growing, more robust server infrastructure – hardware, databases, networking, security and information technology (IT). Then you factor in the cost of hardware equipment, software, licensing, and resources and engineers to support these systems. So moving more into edge computing and the services and connecting to the cloud, the Industry 4.0 initiatives are curbing some of the costs that way.”

That’s good news, but there’s more. “It’s much easier to get started now,” said Cox. “And you can go to scale a lot faster. It’s easier for management and maintenance over the long term. You wouldn’t want to put a thousand edge devices out there and have to manually go to each one of them. You wouldn’t want to drive out there, connect to it, and try to manage it. You want to be able to deploy this solution to all of them at the same time. And that’s what the technologies we have today can do, and that makes it so much more effective.”

Marcy agreed. “Today, you can get a device with MQTT out of the box,” he said. “And it can include the SCADA software and licensing. You can connect it all with a few mouse clicks and be up and running with edge computing without having to architect all that upfront yourself.”

Edge computers also can connect with those at other plants. The edge devices can talk to each other, and there are advantages to sharing the data among locations, but there’s still the risk of a connection disruption between the two plants. Data from edge devices also can be shared with supply chain or other partners. This can speed up interactions and help organizations make better decisions as they consult with partners while everyone looks at the same data. All these connections are easier than ever to implement with today’s edge technologies.

Edge computing’s popularity is growing

More organizations are realizing edge computing’s value. “I think people are understanding the possibilities more,” Marcy said. “If you look at 2015 or 2016 versus today, there’s a lot more market awareness of edge computing. I also think the technology to implement it has really come into its own in the past few years. I think more than anything, customers are asking for solutions that edge computing provides, even if they’re not asking for edge computing specifically.”

“I think there’s more acceptance of this today,” Cox said. “You have the C-level interest, and the trends, and what you can do in the cloud.”

McClain predicts edge computing will continue to aid the trend toward greater IT/OT convergence. Many systems are still proprietary and not IT-friendly.

“When you’re talking about trying to solve IT/OT convergence, adopting a lot of these edge technologies, and the standardization that comes with that, really helps bring those two different groups together and helps in that overarching goal, which really needs to be solved to take manufacturing to the next level,” McClain said.

MQTT is often a key part of edge computing because it requires far less bandwidth than other communication protocols. The publish/subscribe model used for MQTT makes the data available for every entity that needs it – from plant-floor operators to managers to mobile users to top executives to other business units. It reports by exception, rather than wasting bandwidth by reporting the same information over and over. It’s also very flexible, making it easy to send any kind of data in any format.

MQTT also has security advantages. Edge security in general can be strong, said Cox, if people follow the right procedures. “There’s a lot of more technology and encryption out there today that you can take advantage of,” said Cox. “I would argue that the edge actually increases security, especially in the brownfield world because we can put the edge computer in front of that PLC. It could be on a private network, and that computer could have two Ethernet adaptors – one for connecting to the PLC locally and one to send that data to their network or wherever they want to send it. And if I were on that network, I couldn’t talk to that PLC directly without having to go through that computer. And if we lock things down through firewalls and all that, we’re having a much higher degree of security than we had before.”

Edge computing case studies show benefits

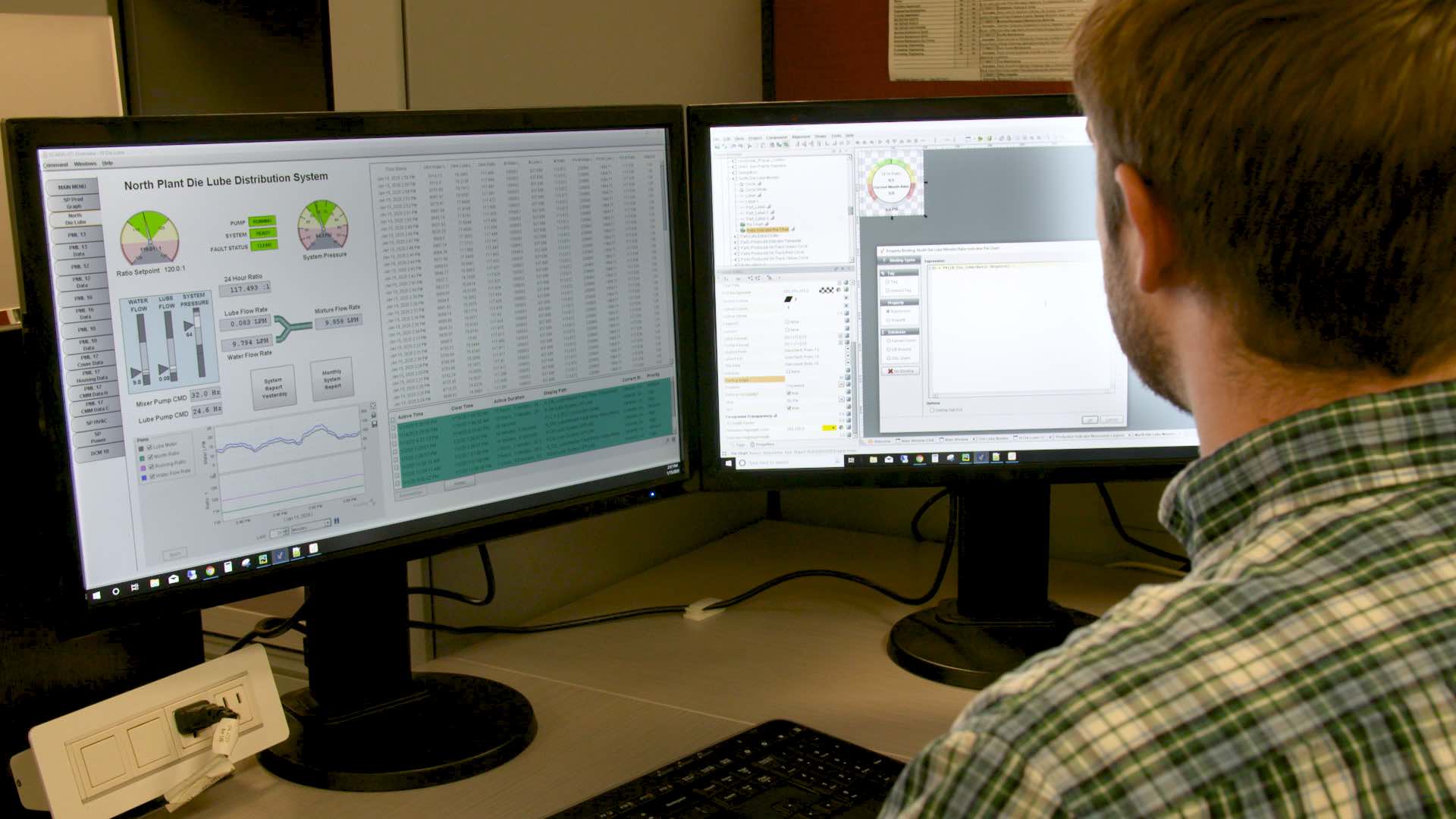

Cox, Marcy, and McClain all mentioned projects their companies have worked on that show the benefits of edge computing.

Xocean is an Irish company with a fleet of uncrewed surface vessels that collect data from oceans. It has clients around the world, and its vessels leverage edge technologies, including MQTT.

“When I look at solutions like Xocean’s, I think not that long ago, it was not possible, but now it is,” said Cox. “That’s because of cellular technology being really good, and because we can put lightweight, cost-effective computers out there. Xocean has an embedded computer on each vessel, and that’s connected to the data, and they’re publishing that data efficiently with MQTT over cellular back to a central system, where they can see the data, and they can manage it. It’s kind of a perfect storm, all these things that had to happen to make that project possible. MQTT had to be there, cellular technologies had to be there, and robust, fast, compute power too, but also cost-effective and rugged.”

MartinCSI is a system integration company that implemented an edge project for a customer in the oil and gas industry. The project collects data from 40 service trucks, easily sending it to the cloud and to mobile devices. Data includes around 20 operating variables per vehicle – items such as winch depth, torsion, and speed, along with things like fuel savings, operating hours, and maintenance alarms.

“That’s a good example of taking the greenfield world where we’re getting brand-new PLCs and control systems that are fundamentally built on open, secure standards,” Cox said. “And we’re able to quickly get the benefit of that and build some very robust, amazing applications. And especially leveraging the cloud with that. Having all these technologies in the cloud is making it kind of a no-brainer for companies and they’re seeing the benefits immediately, and they’re getting that value. Otherwise, of course, they wouldn’t be doing it.”

Corso worked with a company that does pump stations for golf courses and agricultural facilities all over the world. The company wanted to get all its data into the cloud. Corso created a system with Raspberry Pis, MQTT and edge computing to accomplish the client’s goals. It included a map system that allows technicians to troubleshoot an issue from anywhere in the world, without having to physically go to the location. The system provides status, alarms and other data while also providing store-and-forward.

“It helps provide an entirely new revenue stream for them,” Marcy said. “It solves this as a subscription and support cost to their customers – also giving their customers updated visibility and reporting oversights. That’s been a powerful project for them.”

McClain said customers become edge computing fans once they see it in action and get an idea of the tangible results it can produce.

“In general, time and time again, customers are coming back,” he said. “The results, whether it’s in the form of reports, dashboards, visualizations, things like that, those results that they’re getting out of these types of systems and architectures definitely provide the value. And they’re happy with that.”

Jim Meyers is communications manager at Inductive Automation. Inductive Automation is a CFE Media and Technology content partner. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].

MORE ANSWERS

Keywords: edge computing, Industry 4.0, message queuing telemetry transport (MQTT)

CONSIDER THIS

How is your company using edge computing and Industry 4.0?