A cloud-based platform used for plant and process designs provides many benefits such as better collaboration, reduced costs, and scalability.

Now is a very exciting time for the manufacturing and processing industries. Technology is redefining everything from job descriptions and maintenance schedules to how plants and processes are designed from the get-go. To meet today’s market demands, companies need more flexibility, more modularity, and greater efficiency. Engineers, in turn, need to be able to produce designs quickly and accurately. They also need to be able to adapt those designs as new data comes in and new technology is introduced. A cloud-based design platform enables engineers to meet all of these goals in a way that’s cost-effective and efficient. Here are eight reasons why a cloud-based platform should be used for plant and process designs.

1. Collaboration among all stakeholders

Plant design has never been a one-person job and new technologies are bringing more people into the mix. For example, in the food processing and packaging industry, equipment manufacturers have shifted from being suppliers to being consultants, called in to collaborate and advise on process design. A cloud-based platform allows users to quickly collaborate with all stakeholders on a project and keep everyone on the same page. This is especially valuable during the design review and approval process.

2. Faster design iterations

Adding people adds complexity. And, as a rule, complexity slows things down. It doesn’t have to. A cloud-based software provides a centralized database for all of your engineering data. This reduces design time via real-time updates and by eliminating versioning inconsistencies.

3. Improved integration

Contributing to faster design iterations, but deserving of their own section, is integrations. Engineers use a wide variety of tools, including components libraries, information from public databases, and software for functions like modeling and simulation. Cloud computing makes it possible to bring all of these tools under a single umbrella through integrations. This saves time and significantly reduces rework by eliminating the need to import and export data between systems.

4. Mobile access

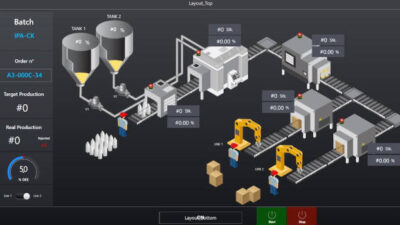

A cloud-based platform allows on-site operators to easily access the engineering data they need from a mobile device. This is useful during planned maintenance, and it’s indispensable in an emergency, when the technician may not discover exactly what they need until they get out there and start poking around.

5. Real-time updates

Say the service technician sent to the windmill makes some adjustments to the equipment. How can the company ensure those adjustments are accurately reflected in the project documentation? In addition to providing remote access to data, a cloud-based platform allows the data to be updated in real time. The technician can enter the modifications and even upload photographs as supporting documentation. Users can set up an approval workflow to maintain data quality, but at least the updates will be provided immediately instead of relying on data entry after the fact.

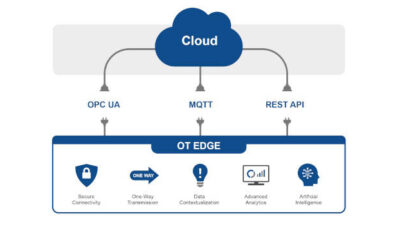

6. Digital twins and the Internet of Things (IoT)

With facilities going more and more digital, more companies are starting to leverage the power of the IoT, including digital twins. In this new world, where machines talk with other machines, the cloud is where everything comes together. Cloud-based platforms provide a way for humans to collect and analyze data from many different sources.

7. Cost savings

Servers are expensive. The hardware itself costs a pretty penny, but that’s nothing next to maintenance and security costs. It’s also mission critical. If the server fails and there isn’t a failover solution in place, users could be without access to engineering data and documentation at a very inauspicious time. A cloud-based platform reduces this burden and significantly reduces IT costs.

8. Scalability

Cloud computing is a scalable solution in a way on-premises software and servers aren’t. If more computing power is needed to run the simulations for a new plant, you’ve got it. This gives more flexibility in the types of projects companies can take on without limiting their on-site hardware capacity.

Compared to some other disciplines, engineering has been somewhat reluctant to move entirely to the cloud. With competition heating up in many industries, and the ever-growing pressure to reduce design time and cost, cloud computing is just around the corner from having its day.

This article originally appeared on Aucotec’s blog. Aucotec is a CFE Media content partner. Edited by Chris Vavra, production editor, Control Engineering, CFE Media, [email protected].