Ensuring safety in explosive environments

There are many requirements and regulations required for equipment used in potentially explosive environments.

In many workplaces, gases, dusts or vapors can be found in the air. If these materials ignite, an explosion could cause damage and injury. Industrial activities, for example vehicle paint spraying, chemical manufacturing, grain flour processing and filling stations are just some of the working environments where explosions could potentially happen.

Certification of equipment used in such environments is designed to minimize or prevent the potential risk of explosion. Therefore, if your production processes involve flammable liquids, gases, vapors or combustible dusts, or if you provide equipment that is used in such places, you may require expert guidance or product/system certification.

CE or UKCA (UK Conformity Mark) marked equipment is safe when operated within a normal environment. However, due to the use of flammable gases, vapors or combustible dusts, some modern industrial environments pose an increased risk of fire and explosion, so equipment must meet the enhanced requirements of applicable regulations and standards.

Within the EU, compliance with the ATEX Directive (2014/34/EU) is required, external to the EU, the IECEx Equipment Certification Scheme applies but is very dependent on the site requirements. For example, CCC is now required for China, HazLoc for North America and InMetro for the Brazilian market.

Following Brexit, in the UK the ATEX Directive has been replaced by the Equipment and Protective Systems Intended for use in Potentially Explosive Atmospheres Regulations 2016 UKSI 2016:1107 (as amended by USI 2019:696) – hereafter referred to as ‘the UKCA Ex Regulation’. However, as EU Directives are already transposed into National Law, the UK already has a legal system in place that applies. This means that for the foreseeable future, the requirements of the UK Regulation will remain the same as those of the EU’s ATEX Directive.

The UKCA Ex Regulation and other certification schemes govern how equipment and workplaces in explosive environments must be managed. Although similar in scope and intent, they have different requirements and assessment approaches, complicating the regulatory approval process.

Potential ignition sources

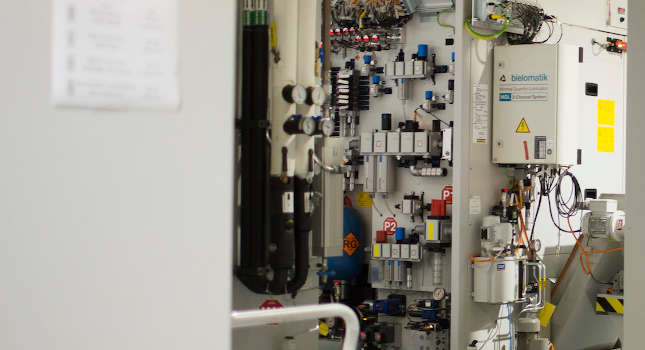

Increasingly, equipment is being used in potentially hazardous environments to automate or control certain production processes, but the normal operation of equipment often involves actions or reactions that are a potential ignition source, such as:

- Electric sparks: A poor quality component or electrical connection can fail, inadvertently producing an electric spark that can ignite gases or nearby materials.

- High operating temperature: Depending upon the particular hazardous atmosphere present, hot surfaces of equipment could cause an auto-ignition. Process system heating effects by ‘work done’ i.e. pumping systems, must also be considered as these can elevate the ‘product’ above its flashpoint.

- Electrostatic discharge: Some normal equipment operations can generate static electricity, which can serve as an ignition source at certain levels.

- Friction sparks: Equipment operation may also involve repeated contact between materials, resulting in friction that can produce heated sparks and material contents must be considered as a potential ignition source.

To be able to eliminate the potential ignition sources, which can include considered faults, prior to manufacture and installation, a pre-assessment is recommended to understand the equipment design, operation and desired location and environment. This can also be carried out for existing non-electrical equipment which was manufactured and installed prior to July 2003.

Tackling hazardous environments

The UKCA Ex Regulation provides a detailed overview of the essential health and safety requirements applicable to equipment used in hazardous environments. However, the specific technical requirements to demonstrate compliance for various types of equipment and operating environments are found in nearly 100 individual harmonized standards. Depending on the equipment and its intended use, this means that more than one harmonized standard may be applicable to the evaluation and certification process.

Under the provisions of the UKCA Ex Regulation, evidence of compliance is generally demonstrated by the issuance of a manufacturer’s, or supplier’s Declaration of Conformity, and the task of demonstrating compliance rests with the party responsible for introducing a product into the marketplace.

External to Europe and the UK, the IECEx conformity mark is evidence that a manufacturer’s products have been independently assessed against the additional requirements of the IECEx conformity mark licensing system. The mark license number is issued to a manufacturer by an accepted IECEx certification body (ExCB) that has entered into a mark license agreement with the IEC.

The primary goals of the IECEx Scheme are to reduce testing and certification cost, speed up market access for new products and equipment, and increase international acceptance of product assessment results. The scheme achieves these goals through the issuance of an International Certificate of Conformity based on:

- Testing and assessment of equipment samples for compliance with applicable international standards.

- Assessment and auditing of a manufacturer’s quality assurance system.

- On-going surveillance audits to ensure continued compliance.

The UKCA Ex Regulation’s conformity assessment process provides a certification route for a broad range of equipment. It also offers significant latitude in the technical assessment of non-conventional equipment through the use of a technical construction file. This can be especially important to manufacturers of customized equipment, or equipment specifically designed for unique applications. However, as the IECEx Certified Equipment Scheme only assesses electrical equipment against TC 31’s IEC standards, this restriction can present an insurmountable hurdle for manufacturers of highly specialized electrical equipment, as relevant standards will not exist.

Confirming compliance

The UKCA Ex Regulation’s conformity assessment process provides a certification route for a broad range of electrical and non-electrical equipment. Under the IECEx Scheme, equipment must be tested and certified by IECEx-approved Testing Laboratories and Certification Bodies, evidence of prior testing conducted by an EU Notified Body or UK Approved Body is not acceptable.

For this reason, the preferred conformity assessment path for many manufacturers has traditionally involved first obtaining equipment certification under the IECEx Certified Equipment Scheme. The IECEx testing data must then be submitted to an EU Notified Body or UK Authorized Body as part of the certification process.

Equipment used in hazardous environments must be expressly designed to minimize risks, and manufacturers of electrical, non-electrical, electronic, mechanical equipment and systems must ensure that their products meet the requirements of applicable regulations and standards. Although similar in scope and intent, it is clear that the UKCA Ex Regulation and the IECEx Scheme encompass different requirements and utilize different assessment approaches, complicating the regulatory approval process for equipment manufacturers supplying multiple regions.

– This originally appeared on Control Engineering Europe’s website. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, cvavra@cfemedia.com.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.