Manufacturers of all sizes are using artificial intelligence (AI) to produce more products faster, at lower cost and less risk.

Artificial intelligence (AI) insights

- Industrial AI revolutionizes manufacturing: AI trains robots for intricate tasks, utilizing synthetic data, doubling production throughput, predicting maintenance, and simulating virtual factories for optimal efficiency.

- AI-driven insights transform operations: Smart devices analyze 3D maps, alerting to anomalies, optimizing workflow, and enhancing quality control, ensuring timely interventions and continuous improvement in production lines.

Artificial intelligence (AI) is helping industrial manufacturers do more – from handling more types of materials and optimizing production lines to making timely maintenance interventions and even building smarter factories. Data from your factory can enable AI to optimize workflow—whether at a single production station or across a facility.

A pilot project is a good place to get started with AI. Experts at Invisible AI, NVIDIA and Siemens shared pertinent use cases of where industrial AI delivers value and makes factories smarter today.

Using synthetic data to pick and place different objects with robots

AI makes it possible for robots to handle new types of materials, even raw poultry. With AI-based training, objects that were previously impossible for robots to identify and manipulate are now within their grasp.

An NVIDIA customer, Soft Robotics, for instance, worked with a food producer to create an AI solution that enables a robot to recognize and pick up single, wet and squishy chicken wings out of a pile of wings. Where does one wing start and end, though? And what’s the best way to grip a specific wing? It’s a challenging task. A pile of chicken wings can form an infinite number of positions or poses.

“This is where the superpower of simulation comes in,” said Gerard Andrews, senior product marketing manager for robotics at NVIDIA.

Rather than taking 10,000 pictures of all the ways chicken parts randomly drop, AI can build photorealistic, physically accurate 3D representations and put them under different lighting conditions, Andrews said. Using the images from the simulation to train the AI model saves time compared with photographing and labeling thousands of real-world images.

Data generated from computer simulations or algorithms is called “synthetic data,” Andrews explained.

“Using the synthetic data, Soft Robotics greatly accelerates how quickly companies can deploy robotic arms in different manufacturing applications to pick and place objects.”

Using outlier cycle detection to double the throughput of a production line

AI also helps management focus their efforts. While factory floor supervisors can’t be everywhere at once, smart devices can. Eric Danziger, CEO at Invisible AI, said ready-to-use smart devices help manufacturers uncover opportunities to optimize assembly lines.

Traditional cameras produce hours and hours of 2D video — and too much information.

“AI makes sense of the pictures and combines the visual input with other types of production data and signals to make a 3D map of people, their tools, current productivity, and cycle time,” Danziger said.

AI insight directs attention to where it’s needed. “AI helps you understand which thing your production team should pay attention to, such as a worker who quietly pushes a button repeatedly to get a balky machine to function but doesn’t alert a supervisor to the ongoing problem.”

Much of this comes down to a process at which Invisible AI excels: Anomalous cycle detection, which analyzes whether a human or machine cycle is performing within an expected range or abnormal.

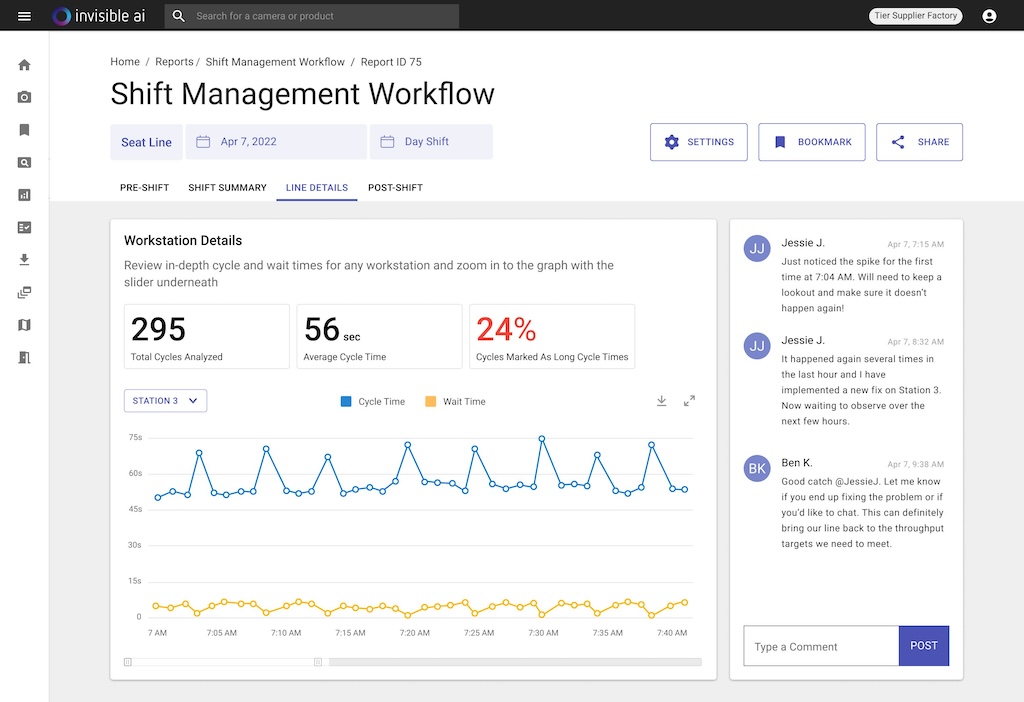

A Tier 2 automotive supplier, for instance, doubled the throughput of a production line with Invisible AI’s help.

“They knew they had a problem line and needed better visibility and better views,” Danziger said. Using AI tools, they identified high spikes in cycle times at some stations, including the workstation shown in the shift management workflow chart below. Frontline operators and managers at the supplier now run shifts and find issues in real time.

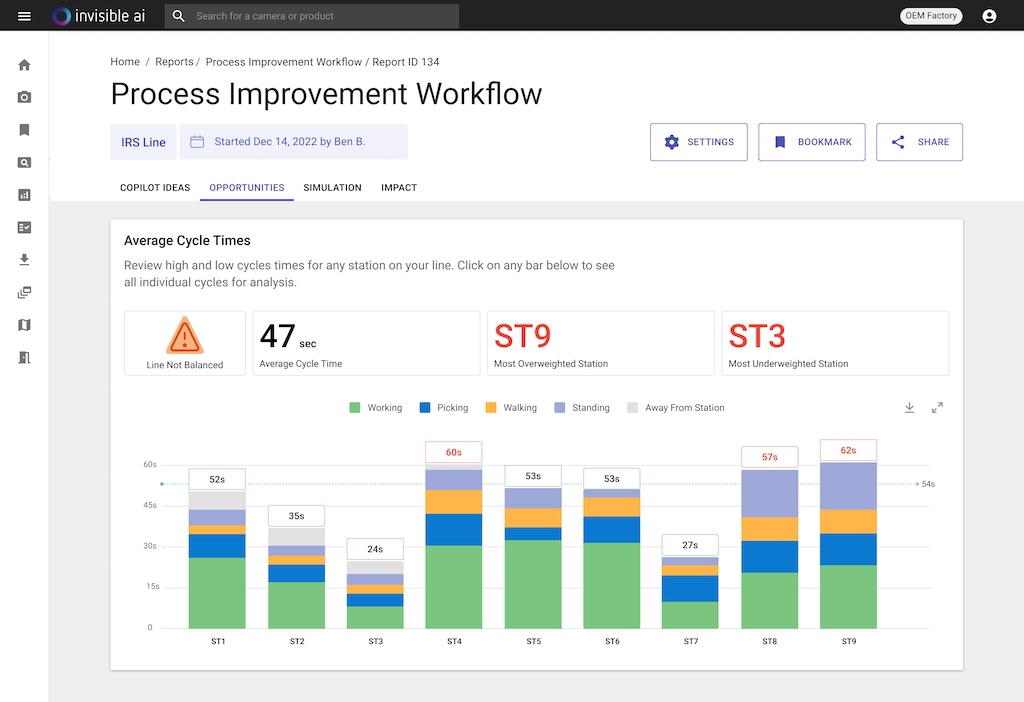

In another case, an automotive OEM partnered with Invisible to identify underutilized stations, as shown in the process improvement workflow chart. The OEM used the insight to consolidate stations and produce 5% more per throughput per shift while reallocating 20% of headcount.

Ensure timely maintenance and quality control

Like a race car driver at a track, timely maintenance and faster pitstops can be a winning approach.

“Predictive maintenance is one of the first things to implement with AI in an industrial setting,” said Bernd Raithel, director of product management and marketing for factory automation at Siemens Digital Industries.

Mechanical parts like bearings wear out and must be replaced routinely, like changing the engine oil in a car based on distance traveled.

“AI predicts that Machine A is going to fail with a stated confidence level in the next two days,” Raithel said, so the maintenance team knows to replace the bearings before they get stuck. A short, planned maintenance shutdown results in less loss of production than an extended, unplanned outage.

Prescriptive maintenance is a step beyond predictive maintenance. Although the two terms sound similar, prescriptive maintenance keeps more complex equipment running. AI may adjust the operations of the equipment to keep it going. And “prescriptive maintenance gives some ideas up front about what component is about to fail and what parts the technician needs to fix the machine,” Raithel said.

Successful AI requires data from production processes. When the public sees AI in action, the vendor has already performed the AI training. In contrast, for industrial manufacturers, the first step is to collect enough data on which to base decisions,” Raithel said. “There’s often a lot of data already available from machines.”

Siemens, for instance, used a wealth of production data to increase throughput of a production line of printed circuit boards by performing 30% fewer x-ray tests. They accomplished this task using AI to identify which boards were likely to benefit from inspection. The company collected large amounts of processes, parameters and other information about test results to feed the AI model as well as correlating 40,000 production parameters.

With the data, Raithel said, Siemens learned which parts were defective as well as the source of the defects, which the company used to further improve quality.

Simulate new factories and processes with agility

New factory design and process changes involve risks that can be reduced through a 3D simulation in a type of virtual factory, otherwise known as a digital twin.

Linked to existing systems, a digital twin looks and works like the real-world factory it simulates. The industrial metaverse, a 3D virtual world built specifically for industrial manufacturers, makes this possible. These virtual environments also help to generate synthetic data to train AI/ML algorithms. In a recently announced partnership, NVIDIA and Siemens announced plans to bring the industrial metaverse to industrial customers of all sizes.

A FREYR virtual battery factory, for instance, provides 3D representations of the infrastructure, plant, machinery, equipment, human ergonomics, safety information, robots, automated guided vehicles, and detailed product and production simulations.

A digital twin of a BMW automotive factory is another example. With simulation, the entire planning phase of the manufacturing facility can happen in a virtual world, and everything can be tried out and tested. “The OEM knows with a high-level of confidence that a system is going to run and achieve the throughput on day one,” Andrews said.

From grasping chicken parts to building entire virtual factories, industrial manufacturers are using AI in the real and virtual worlds. The opportunities to increase agility and optimization through AI are (virtually) limitless.

– The Association for Advancing Automation (A3) is a CFE Media and Technology content partner.