Secure, granular data processing, connectivity, and communication in the field create a foundation for large-scale IIoT according to a company with a Control Engineering Engineers’ Choice Award product.

Learning Objectives

- Plan to scale up in the physical layer and consider new architectures for an IIoT infrastructure.

- Put cybersecurity first in an IIoT infrastructure to deliver meaningful data where it need to go.

- Explore edge data processing for the IIoT infrastructure.

Wondering how to build out an Industrial Internet of Things (IIoT) infrastructure? IIoT efficiently addresses large-scale applications like performance monitoring, predictive maintenance, and digital transformation. Achieving scalability is the key, but traditional approaches create too much complexity to enable cost-effective growth. Edge input/output (I/O) systems simplify the process. Here’s how you can get started.

Plan to scale up in the physical layer for an IIoT infrastructure

The labor involved to install, configure, and integrate I/O plays an important role in the overall scalability of an IIoT system. The more complex and time-intensive the start-up, the more obstacles there are to integrating additional equipment. To help achieve scalability, edge I/O systems may provide options that help streamline this physical and intellectual labor. Power over Ethernet, for example, reduces the number of components and the size of the enclosure required to safely install an edge I/O device. Web-based configuration reduces the tools and training required to prepare a device for operation. For a rollout, consider the time required to install and configure each node and how to use features to make the process repeatable.

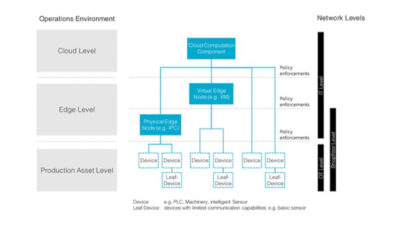

Consider new architectures for an IIoT infrastructure

Edge-oriented architectures locate processing and communications resources in the field (or on the plant floor) rather than in the network core. In addition to providing their specific functions, such as universal I/O sensing, protocol translation, or power monitoring, edge I/O devices are designed to stand on their own as first-class citizens in a distributed network. Each device can operate independently of higher-level systems, allowing the low-level infrastructure to grow or change with minimal impact on the rest of the network. The final result can look very different from a traditional automation network, but don’t let that be a hang-up. A flexible, low-level infrastructure is key to designing for “everyday IIoT” because it enables incremental expansion and reconfiguration of the system.

Put cybersecurity first in an IIoT infrastructure

Of all the configuration options available, cybersecurity deserves extra attention. It’s unwise to expand a network without taking safeguards. Cybersecurity concerns have limited the scalability of traditional automation. It tends to push information technology (IT) groups toward draconian security policies that inhibit basic IIoT goals. IT teams may increase network complexity by adding security devices and software.

Edge I/O addresses the realities of life on the network by providing standard cybersecurity technologies and techniques like user authentication, firewalls, and SSL/TLS encryption, to name a few. These have been common in IT devices for a long time, so when setting cybersecurity tools up on the operational technology (OT) side, it contributes to interoperability with IT systems and trust-building with IT stakeholders.

Show me the data as part of the IIoT infrastructure

Edge I/O devices affect scalability through the combination of OT and IT communication protocols they support. OT communication options can range from traditional wired I/O to serial devices and programmable logic controller (PLC) data, but OT integration is only part of the solution. The true value of edge I/O comes in democratizing OT data by providing options compatible with IT systems. Support for essential networking services like DNS/DHCP or communication options like REST APIs or MQTT makes it easier to move data from the field to consumers in business networks and external endpoints. Take the time to understand these protocols and plan the system. Using the right protocols will have a significant impact on how a system can expand and share data.

Explore edge data processing for the IIoT infrastructure

A common objective for early IIoT projects is to focus the system on transporting data to cloud services for processing and analysis. However, raw data streams are costly to transport, store, and process, and may result in the end of a project due to budget overruns.

A more scalable approach uses edge-oriented processing to streamline the quantity and improve the quality of data sent to central processing services. Edge I/O is small enough that processing power can be highly distributed. You can use it to filter noise from raw signal data, aggregate data from multiple sensors, add contextual metadata, or package time-series data into interoperable exchange formats such as JSON. All of this effort at the edge provides clean data throughout the system and reduces later communication and number-crunching costs.

When considering how to build out an IIoT infrastructure, plan to double down on these attributes of edge I/O’s scalability for a rollout that progresses smoothly and grows to capture every piece of data across a facility.

Josh Eastburn is director of technical marketing, Opto 22. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: IIoT infrastructure advice, Engineers’ Choice Awards

CONSIDER THIS

How are you using edge I/O devices to improve operations?