A sampling of exhibits at ProMat 2023 demonstrate advances in automation and control help warehousing, distribution centers and other motion control applications. See videos.

Learning Objectives

- Motion control advances, robotics help warehousing, distribution centers and logistics in factories, as shown by ProMat 2023 exhibitors.

- Sensors, integrated systems, motors, intralogistics design services and product tracking help distribution centers, factory motion control, and warehousing applications demonstrated at ProMat 2023.

- Get a more in-depth understanding of the different approaches on using technical resources manuals and the energy-efficiency measures. Learn about specific energy-efficiency measures used in incentive programs for air handling systems and equipment.

Warehousing, distribution center insights

At ProMat 2023 by MHI, exhibitors demonstrated how motion-control advances and robotics help warehousing, distribution centers and logistics in factories.

Sensors, integrated systems, motors, intralogistics design services and product tracking are helping to optimize distribution centers, factory motion control and warehousing applications, as demonstrated at ProMat 2023 by MHI.

ProMat 2023 was the largest event in MHI history, with a reported 12% increase in registered attendees compared to the last pre-pandemic show, with a total of 50,924 in the 4-day March show and conference at McCormick Place in Chicago. With 562,700 net square feet of exhibits (more than 1000 booths), covering 1.2 million square feet, it also had more than 150 educational sessions, at ProMat 2023, March 20-23, in Chicago, organized by MHI.

A sampling of exhibits covering automation, safety, logistics, robotics and other solutions that can be applied to motion control for manufacturing, warehousing, distribution centers and other applications.

ifm efector offerings include automation hardware, software and networking and communications.

Garret Place, business development, robotics perception at ifm efector, said manufacturing demand continues to outpace labor availability leading to more automation. For mobile robotics, 2012 was an inflection point for larger companies, Place said, but smaller and mid-sized firms still aren’t getting the benefits they should. Faster easier technology integration could help.

The ifm efector Edge Perception Processing Unit helps mobile robots make sense of their surroundings more quickly and keep moving. (photo)

The ifm efector vision assistant helps with load tracking and obstacle detection so the robot maker can focus more easily on robot functions. (photo)

End-users can monitor machine health more easily with ifm efector moneo software that uses sensor data to monitors vibrations and communicates with cloud-based tools to identify trends.

Inventory becomes easier with the ifm efector RFID Gate Tracking solution. Sensor on gates or around doors gather data from RFID tags on products inside boxes or attached to boxes and/or pallets and provide counts in real time as they move past the sensing area in either direction. (photo)

THK Timken provides high-resolution encoders (position sensors) that go into robotic arm joints to provide precise measurement with 4.5 million counts per turn. On a different scale, that would be the equivalent to one dot every foot between Chicago and New York City, according to Timken. Photo shows the shape of the magnetic encoders that enable that precision. ABS, absolute position encoders, for framed and frameless servo motors, have robust resistance to external magnetic fields, dirt and vibration.

Kollmorgen (Regal Rexnord) discussed NDC Solutions, one system for a fleet of automated guided vehicles (AGVs) and mobile robots, covering vehicle control, including multiple navigation types and any wheel configuration. The system supports any type of AGV and mobile robots, not just those using Kollmorgen programmable logic controllers (PLCs), motors and drives.

Westfalia’s Dan Duffy, a controls engineer, said automated storage and retrieval systems (ASRS) solutions are expanding beyond traditional warehousing applications into food and beverage and other markets. Easier interfaces to other systems and energy savings are two recent ways ASRS solutions are gaining traction.

Lapeyre Stair showed, if your motion-control system is in the way, how a compact, alternating-tread stair design can fit over a conveyor, providing a mobile, lower-risk alternative to using ladders to get over conveyors. (photo)

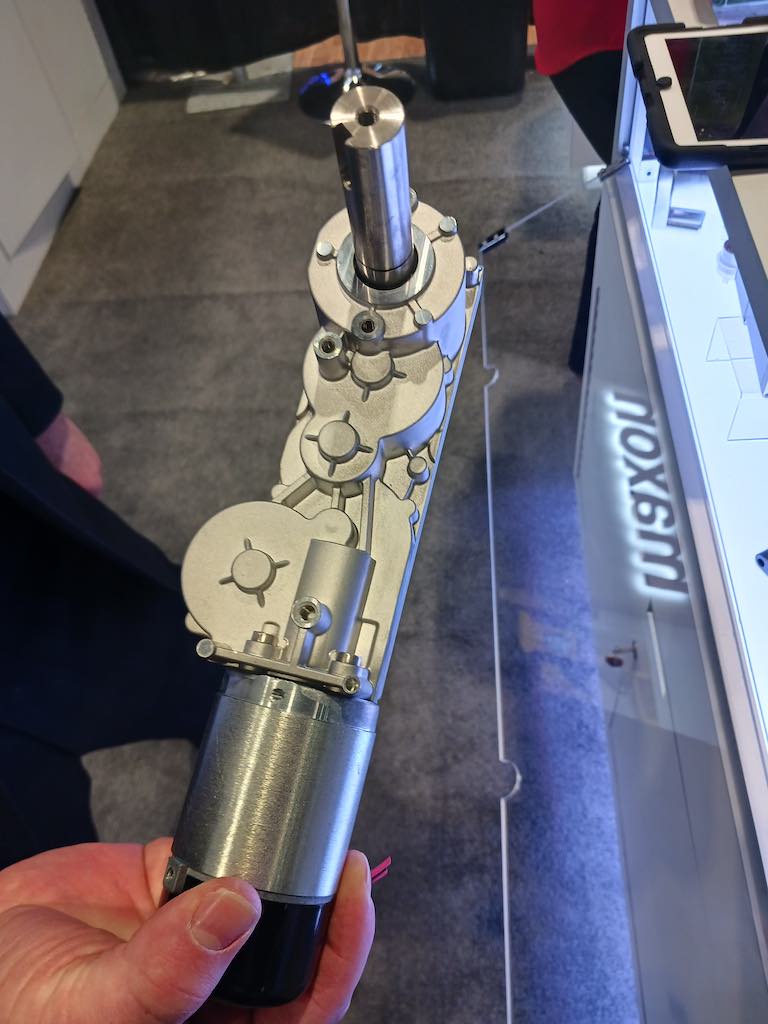

parvalux by maxon makes fractional-horsepower geared, electric motors, many to fit specific application needs, with rapid prototyping capabilities to speed time from design to market, according to John Uzzolino, parvalux business development manager. maxon purchased the now 75-year-old parvalux about 4 years ago and is aiming to increase awareness of its capabilities for brushed and brushless motors, in-line gear boxes, and motor controllers.

By creating a compact design and integrating what is needed for an original equipment manufacturer or robotic manufacturers, parvalux can save considerable system integration and time in the design and manufacturing processes by integrating motor, gears, connectors, power and electronics, input/output (I/O) points, subsystems and packaging as needed, including a drive, if the configuration requires. About 80% of its offerings include some customization, Uzzolino said.

Integrating gear boxes can bring lower speeds and higher torques to applications that otherwise couldn’t be served by motors in a direct-drive configuration. (photo) Widely varied applications include diverse industrial processes, equipment and commercial designs, such as stair lifts, electric bicycles, robots, warehouse automation, elevators, agriculture and others.

Offerings displayed included parvalux by maxon SC 50/15 Controller (photo), a brushless direct current (BLDC)/permanent magnet dc (PMDC) motor controller. With a PMDC motor, the SC50/15 can operate speeds of 5000 to 15,000 rpm in a closed-loop configuration; open loop use depends on motor and controller output voltage. BLDC use ranges from 2500 to 30,000 rpm, depending on configuration.

The GB65 right-angled gearbox from parvalux by maxon delivers up to 300 Nm torque and high radial loads over 2300N. It supports shaft diameters up to 35 mm and hollow shaft up to 20 mm and is sealed and lubricated for life. Gear ratio options are 60:1, 80:1, 100:1, 120:1 and 160:1. Custom system design configurations are possible.

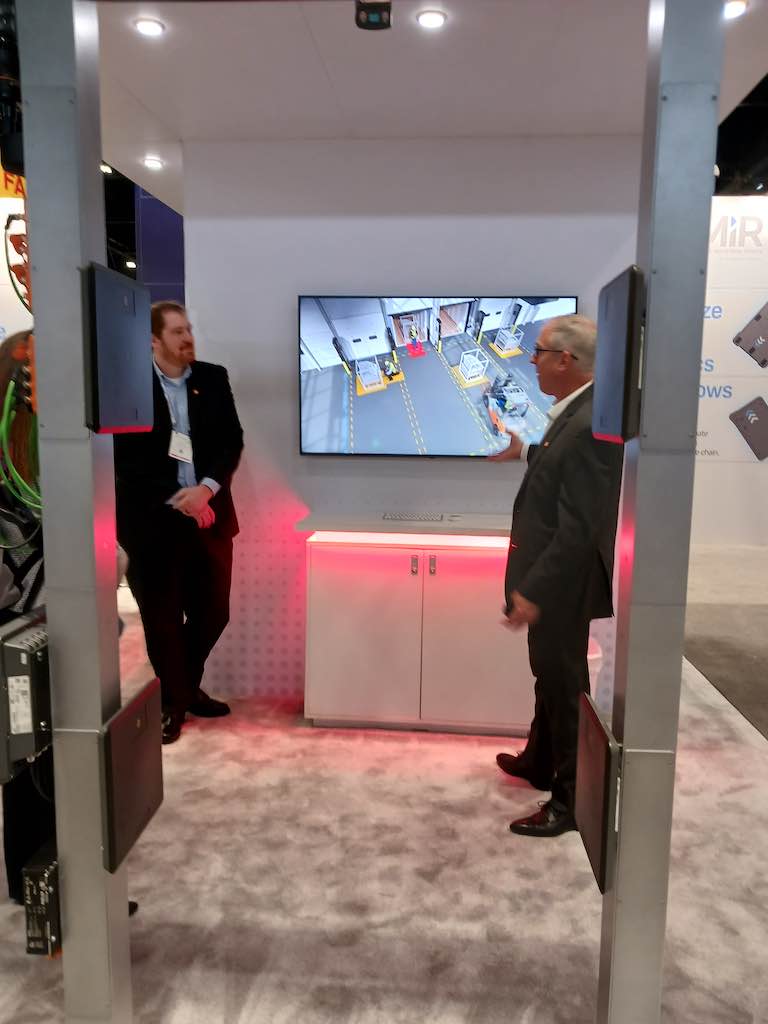

Burns & McDonnell, an architectural, engineering design and construction firm, was explaining its expertise in designing warehouse automation, automated storage and retrieval systems (ASRS), cold storage systems and tote shuttle systems. When companies are paying upwards of $30 per hour for people to pick items to fill orders, it is important to examine options before adding warehouse space, including making existing spaces more efficient with modern automation. In 2019, employee-owned Burns & McDonnell formed a business and technology consultancy called 1898 & Co. for asset-intensive industries the company serves, including manufacturing, chemicals, oil and gas, power, water and other areas.

Fenner Drives and Fenner Precision Polymers, parts of Michelin Group Co., offered information on products to reduce conveyor maintenance for warehouses, distribution centers and manufacturing. Eagle XLD O-Rings from Fenner Drives last six times as long as traditional conveyor. Beyond longer life, the design “optimizes the contact patch of the belt while the strength of the higher modulus provides highly efficient, dynamic load transfer. Existing O-rings with round belts allow 5 rollers in each direction from 3 motors on a conveyor, while using the Eagle XLD solution allows 1 motor with 15 rollers in each direction.

Zebra Technologies has expanded beyond industrial printers, labeling systems, barcodes readers and radio frequency technology (RFID) with its acquisitions of Fetch Robotics (2021) and Matrox Imaging (2023) and showed extensive technology integration at ProMat 2023 with a replica warehouse on the show floor.

Systems integrated inventory at the receiving area, barcode and RFID scanning, rugged tablet-based monitoring, pick-and-place robots, mobile robots, human-guided picks for fulfillment, handheld wearable computers, industrial printers, tote-delivering mobile robots and pallet and case moving. An extensive partner network eases integration with other products.

With just a few hours of setup, mobile robots navigate after being walked around to map location of fixed structures. A more extensive setup can take days rather than weeks.

Zebra devices easily paired with computers and robots. Ivanti partner booth provided a demonstration of voice picking with the Zebra WS50 wearable computer. Zebra’s customer BMC Fashion was pairing Fetch Robotics RollerTop mobile robots with Zebra FIS/MV imagers.

Yaskawa Motoman showed robotic automation adds productivity, optimizes processes, improves product quality and reduces operational costs. Demonstrations highlighted robotic palletizing, parcel induction and other material handling and motion-control advantages.

Mark T. Hoske is content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: Mobile robots for manufacturing, warehouses, distribution centers

CONSIDER THIS

How can automation advances help how you’re moving from raw materials to finished products?