By forming the Siemens Intralogistics vertical, the company can focus hardware, software and services for distribution centers, warehousing and motion control and material handling for manufacturing.

Learning Objectives

- Understand how a material handling focus can help manufacturers, distribution centers and warehouses.

- Learn how software enables virtual commissioning for a material-handling facility.

- Review ProMat 2023 Siemens product announcements.

Warehousing, distribution center insights

- A material handling focus can help manufacturers, distribution centers and warehouses, as Siemens explained at ProMat 2023.

- Software enables virtual commissioning for a material-handling facility and Siemens new product advancements provide additional help.

Siemens Intralogistics offers products, services, hardware and software to help with supply chain and labor issues, applying automation, large and small, using simulation software throughout to optimize before pouring concrete, as explained by Joel Thomas, director of Intralogistics, leading the new Siemens vertical market group at ProMat 2023, March 20-23, in Chicago, organized by MHI.

“Thomas will also work closely with trade associations who serve the intralogistics industry and will foster programs at Siemens to educate the next generation of engineers, programmers, software developers and plant operations personnel who will manage the warehouses of the future,” Siemens said in the announcement about the vertical.

Closed-loop digitalization uses data from the real world to create accurate simulations and find and resolve any bottlenecks in design. System integrators and end users in material handling understand and learn how automation can improve operations, making it more horizontally and vertically sustainable.

Advantages of material handling focus

Many applications need to consider different topologies of controls.

By providing a focus on material handling, Siemens Logistics can:

-

Provide an assessment and uncover any roadblocks during the planning stage when they are most economical to resolve.

-

Use software to create a digital thread that integrates with partners’ products and software.

-

Find ways to make lives easier with tools for better ergonomics, hardware, software and integrating safety and other elements as needed.

The ProMat booth provided examples. Siemens artificial intelligence software, Siemens 1500 PLC (programmable logic controller) and the FlexGrasp Multifunction Platform (MFP) enable configuration rather than programming for logistics applications. A robot demonstrated pick-and-place capabilities with a diverse range of products in a bin. A diversity of robots, vision systems and end-of-arm tooling (EoAT) may be used.

Using integrated software for plant simulation and robotic simulation saves time and effort during planning, design, implementation and throughout the lifecycle, Thomas explained. Calculations can include conveyor friction, finite element analysis (FEA) and vibration. Offline robotic programming can be performed within safety zones then downloaded to any brand robot. Simulation with robotics can optimize movements (grab, arm paths and place) using kinematics and the layout of the workcell.

Virtual commissioning for a distribution center

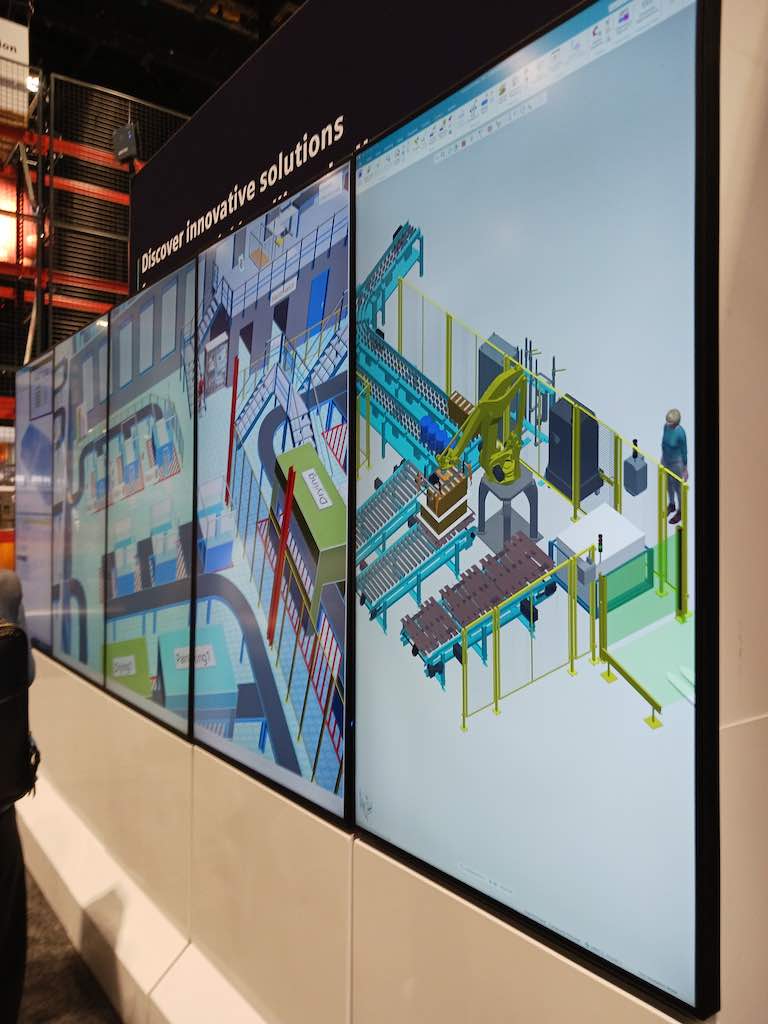

Software was shown in a virtual commissioning demonstration (photo) with 15 conveyors, 16 PLCs and real code, providing specific use cases for service lifecycle management. Tools can work to scan and update models with as-built configurations, to create reliable virtual representations and run real orders with simulations, for trouble-shooting and to minimize or avoid distribution center outages.

Photos show a simulated distribution center on large vertical screens, including movement of totes. Most customers are just doing pieces, Thomas said; the tools displayed tie it altogether, justifying the investment on distribution centers, which may include $10 billion to $100 billion in total investments. Siemens Xcelerator software does the simulation in real time without any performance loss from the controllers.

ProMat 2023: Siemens product announcements

The Siemens ProMat media materials also highlighted:

A new micro-drive for intralogistics applications: Siemens is extending its drive portfolio in the extra-low-voltage range for 24-48V EC motors with its new Siemens Simatic Micro-Drive. The new product line with UL- and CE-marked components consists of the PDC (Profidrive Control) servo drive in conjunction with a flexible range of motors and connecting cables from product partners, along with the technology module (TM) format with servo and stepper drives in a compact 20mm width that can be used with distributed or open controllers.

A new Siemens Sinamics G115D distributed drive for conveyor applications: This new, compact and powerful drive system is designed for horizontal conveyor applications. The drive system comprises the motor, drive and gearbox in one unit and is offered in two versions — wall-mounted and motor-mounted. It has a robust design with a high IP protection class (up to IP66 / UL Type 4X) making it suitable for use in harsh environments.

Location intelligence in intralogistics: Siemens Location Intelligence software expands the Siemens Simatic RTLS (real-time locating system) locating platform to include the digital twin of performance and warehouse. The web-based software analyzes and visualizes dynamic data, processes events and can be addressed from local enterprise resource planning (ERP) or manufacturing execution system (MES) software. The intelligence acquired based on position data provides the user with a comprehensive overview of material flow, order information or possible problem areas. The transponder ID is linked to the existing order data. Depending upon the process step and order status, order information then can be displayed on the Simatic RTLS ePaper transponders, providing a paperless solution.

A new Siemens Totally Integrated Automation Portal: The new version of TIA Portal is designed to boost engineering efficiency with optimized functionalities for multi-user engineering, allowing users to work in teams and parallel on projects and build and manage shared libraries. Access rights can be assigned individually or by group, making collaboration more flexible. By integrating Simatic Automation Xpansion (Simatic AX) Version 18 of TIA Portal software provides IT professionals with a familiar development environment based on Microsoft Visual Studio Code and version control via GitLab.

Standardization in automation: Siemens is pioneering standardization in automation vertically in the factory and horizontally across machinery. After Siemens pioneered operational technology (OT) standardization with the TIA portfolio of hardware, software and services, complemented by a common software engineering framework, the TIA Portal, the next step in integrating automation across factories include motion control, safety, IT and OT unifying plant automation technologies.

Mark T. Hoske is content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: Mobile robots for manufacturing, warehouses, distribution centers

CONSIDER THIS

How can automation advances help with moving from raw materials to finished products?