Case study, Shell Deepwater: Detailed digital twin model used with major industrial automation and operations projects in energy management can reduce time to find critical information by half, with other savings, said Bentley Systems at the 2024 ARC Industry Forum.

Learning Objectives

- Understand how software for digital twin and energy project management helped through a case study of Shell Deepwater workflows, integration, visualization and other benefits discussed at a 2024 ARC Industry Forum news conference.

- Explore how digital twins and project management software help with examples, software features and links to more information, including another article and video.

Digital twin, project management insights

- Bentley System software for digital twin and energy project management helped Shell Deepwater workflows, integration, visualization and delivered other benefits, as discussed at a 2024 ARC Industry Forum news conference.

- Digital twins and project management software features enhance complex projects; see links to more information, including another article and video.

A detailed digital twin model used with major industrial automation and operations projects in energy management can result in up to 10% improved collaboration with vendors and contractors, 10% streamlined and enhanced design and project review workflows, up to 50% reduced time finding critical information, Rob Harper, director of energy product management, Bentley Systems Inc., told media and analysts at a 2024 ARC Leadership Forum news conference (Figure 1).

Case study: Shell Deepwater workflows, integration, visualization

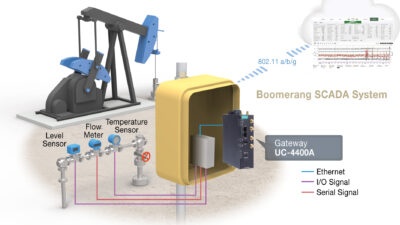

Bentley Systems, a company with $1.1 billion revenue and 5,200 employed in 194 countries, supplies software to design, build and operate the world’s infrastructure, Harper explained. For the Shell Deepwater project, Bentley Systems supplied end-to-end project delivery workflows, integration and visualization of data from specialized subsea design tools, bathymetry, geohazard and other sources. (Figure 2). The tools, Harper said, supply a single view of the truth from project conception in early design phase through handover and deliver of the digital twin.

Digital twins (Figure 3), Harper said, are revolutionizing energy infrastructure delivery, by:

-

Swiftly sharing information with a diverse project team.

-

Ensuring data availability at every project stage to minimize time and cost overruns.

-

Accelerating the project lifecycle form the early design phase to handover and operations.

Software to help with digital twins and project management

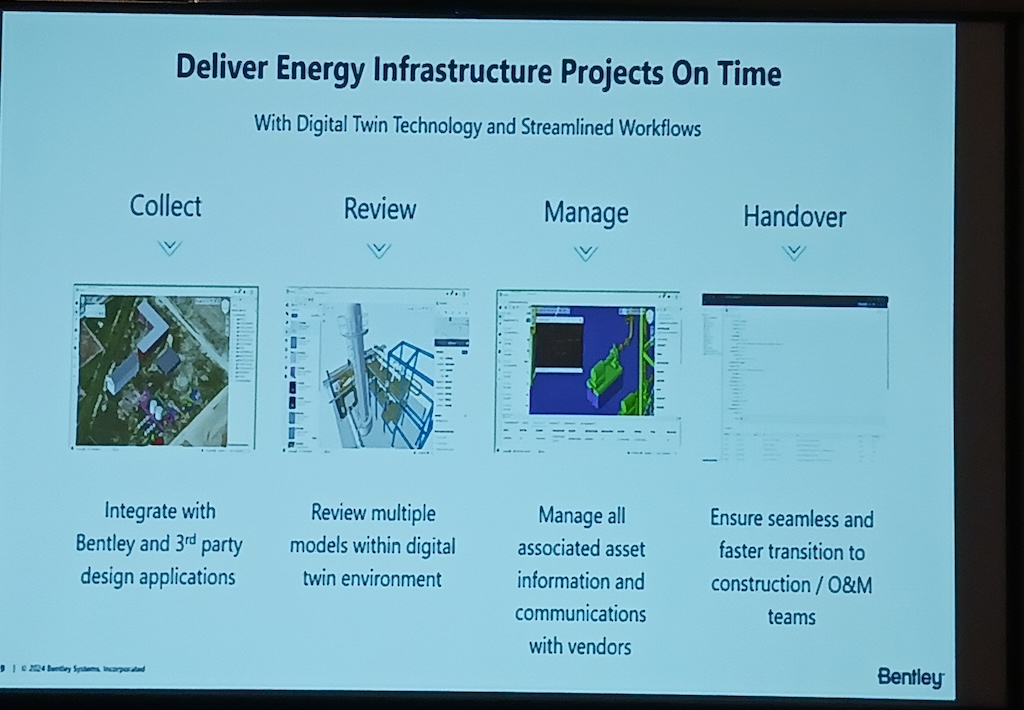

Enabling tools (Figure 4) for the project included Bentley Energy Asset Integrated Delivery software with Infrastructure Cloud, iTwin Platform and Open Applications. Use of digital twin and streamlined workflow software help deliver energy infrastructure projects on time, Harper said, by:

-

Collecting and integrating with Bentley and third-party design applications.

-

Reviewing multiple models within the digital twin environment.

-

Managing associated asset information and communications with vendors.

-

Handing over the digital twin to ensure a seamless and faster transition to construction and operations and maintenance (O&M) teams.

Benefits summary of digital twin, project management software, video

Harper cited benefits of up to 10% improved collaboration with vendors and contractors, 5% to 10% streamlined and enhanced design and project review workflows and up to 50% reduced time related to finding critical information. Energy production improves with an energy asset integrated delivery solution. A single view repository holds comprehensive project data. It includes full control of configuration management and change management, with engineering design reviews and validation along with enterprise interoperability. Full asset information management includes document management. With open and interoperable connections to other systems, users and project partners can collaborate, collect, review, manage and handover information as needed.

A point of concern with digital twins is updating the models. Harper said the user’s 3D model has connector technologies to bring in changes or differences, as needed as when changes are made or at scheduled times throughout the project and asset lifecycle. This isn’t a new database, but a connected visualization of what already exists, he noted. Queries can be run to get information as needed. Learn more from Bentley Systems on digital twins and video from Josh Etkind, Shell Deepwater digital transformation manager.

Mark T. Hoske is content manager, Control Engineering, CFE Media and Technology, [email protected], with materials from Bentley.

KEYWORDS: Open, interoperable automation architecture; distributed control node

CONSIDER THIS

If you have energy and automation project demands that seem out of reach, digital twins and project management software can help.

ONLINE

https://www.controleng.com/digital-transformation/digital-twins/

https://www.controleng.com/control-systems/plm-control-design/

https://www.controleng.com/system-integration/project-management/