Engineers at the University of Wisconsin-Madison have produced a free-standing membrane of the Heusler compound gadolinium-platinum-antimony and can induce magnetism in the thin membrane by straining it.

In 1903, German mining engineer and chemist Carl Ludwig David Friedrich Heusler published the first description of the class of intermetallic alloys that bear his name. Today, he likely would be thrilled at how important those alloys may become in 21st-century computing.

Heusler compounds, which have tunable magnetic and electronic properties, have the potential to enable unique types of electronic devices with functionality beyond silicon-based transistors. Engineers at the University of Wisconsin-Madison have discovered a technique for inducing magnetism in those promising materials.

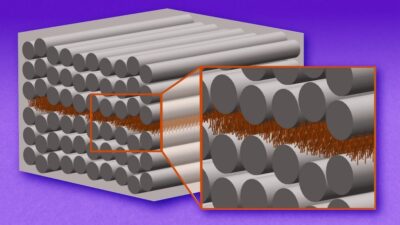

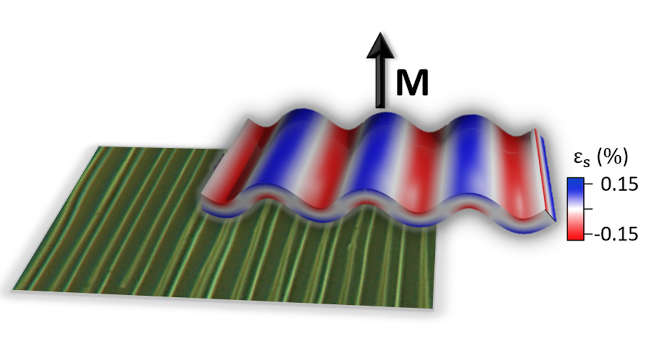

The researchers have produced a free-standing membrane of the Heusler compound gadolinium-platinum-antimony. By mechanically straining it, they can induce magnetism in the thin membrane.

“We knew this material had a similar crystal structure and composition as those exhibiting interesting magnetic, topological, and ferroelectric properties,” said Jason Kawasaki, an assistant professor of materials science and engineering at UW-Madison who led the research. “Our expectation was that with just a little kick, in the form of strain, we could induce magnetic ordering. But traditional methods for applying strain to crystals and thin films are quite limited.”

That’s why he and his collaborators decided to try the new technique. Researchers are looking beyond silicon to new classes of materials with different properties, including magnetism, to advance the next generation of computing. Much of that research is focused on thin films, which are layers of crystalline materials just a few nanometers thick.

Microscope image of rippled GdPtSb membrane on polyimide tape overlaid with a cartoon of simulated strain distribution in rippled membranes. Courtesy: Dongxue Du, UW-Madison[/caption]

One future hope is this Heusler membrane, or another variation, could replace silicon semiconductors in random access memory (RAM), the high-speed, short-term memory in computers. Currently, RAM is volatile, meaning it loses all information when the power is turned off. However, using a ferromagnetic or ferroelectric material like a Heusler compound would make RAM much more energy-efficient, faster and non-volatile, meaning data could be stored even when the electricity is off.

“There are many applications we can envision because these compounds exhibit a delicate balance of competing interactions. With just a small kick, in the form of strain, we can tip that balance to induce dramatic changes in properties,” Kawasaki said. “The fundamental challenges are in growing these materials with the requisite atomic-scale precision.”

– Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].