Video: New control platform to unify Yaskawa controls, motion, robotics, as explained in a Pack Expo Las Vegas interview.

Learning Objectives

- Understand how faster, unified motion controls integrated with safety and robotics can simplify applications.

- See how machine vision and configuration software can ease robot use.

Industrial motion control, robotic insights

- Faster, unified motion controls integrated with safety and robotics can simplify applications, explained Yaskawa America at Pack Expo Las Vegas 2023.

- See how machine vision and configuration software can ease robot use.

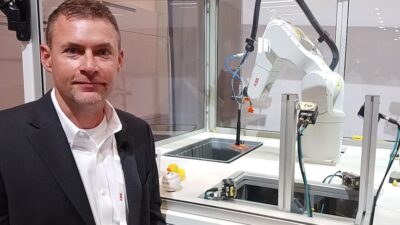

The new I3 Control machine control and safety platform from Yaskawa was discussed at Pack Expo Las Vegas 2023. Jeff Pike, director motion group marketing, Yaskawa America Inc., explained some benefits of the I3 platform (pronounced “I” cubed), expected to be launched globally in spring 2024. Pike said the Yaskawa machine controller also is available with an integrated with a safety PLC to accomplish machine control, logic, human-machine interface (HMI) and safety in one hardware. All the safety programming can be done in the same software used for machine control.

The controller includes a Yaskawa multi-core ASIC specifically for motion control, running the Linux real-time operating system. It’s roughly 40% faster than the fastest Yaskawa controller now available, Pike said. It includes high-speed memory support and all major fieldbus interfaces. Eventually, the new platform controller will be come the core for all controllers, motion and robotics.

Other motion control, connected automation

In the video, Pike also covers other Yaskawa products, including human-machine interface, I/O modules with fieldbus capabilities, rotary servo motors (50 W to 50 kW), with or without gearheads, linear motors and variable frequency drives, along with new food-grade and hygienic stainless motors (photo) for use with Yaskawa Sigma Series servo amplifiers.

Yaskawa Motoman robots, peripherals

Also in the booth, Yaskawa America Motoman Robotic Division demonstrated robotics and connecting peripherals, including:

-

A new 3D bin picking demo with an extended-reach robot and Keyence 3D vision system (photo)

-

A newly updated robotic induction workcell with Plus One Robotics’ PickOne Perception Kit

-

Collaborative palletizing demo with a 30-kg payload cobot

-

New easy-to-use smart pendant extension apps that enable quick development of packaging and palletizing tasks. Chris Caldwell, product manager, Yaskawa America Motoman Robotics Division, explains benefits in a 30-second video clip.

Chris Caldwell, product manager, Yaskawa America Motoman Robotics Division, explains benefits of new easy-to-use smart pendant extension apps. The 30-second video clip explains how the software helps even those unfamiliar with robot programming to quickly develop of packaging and palletizing tasks for robots. Courtesy: Control Engineering

From off-camera, Chris Caldwell, product manager, Yaskawa America Motoman Robotics Division, explains how machine vision guides a robot for part picking, in this case, nudging the small robot “parts” until a clean pick can be made. Courtesy: Control Engineering

Mark T. Hoske is content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: Yaskawa America, Motoman robots, integrated motion control

CONSIDER THIS

Are your motion control and robotic applications where they need to be?