Multiple global machine vision organizations updated Automate 2025 session attendees on machine vision standards, including the G3 effort to coordinate machine vision standardization.

Machine vision standards insights

- Four machine vision standards organizations cooperate to avoid duplication, provide education and work on interoperability events together, as A3, EMVA, JIIA and VDMA explained at Automate 2025.

- A3 machine vision standards update included Camera Link HS, GigE Vision and USB3 Vision; EMVA machine vision standards update included ISO-24942 (EMVA 1288) and GeniCam.

- JIIA machine vision standards update included CoaXpress and SLVS-EC; VDMA machine vision standards update included discussion of how the OPC Machine Vision initiative and VDI/VDE/VDMA 2632.

A3, EMVA, JIIA and VDMA, four organizations involved in industrial machine vision standards, provided a global vision standards update at Automate 2025, by the Association for Advancing Automation (A3). The show and conference are in Detroit, May 12-16, with more than 875 exhibitors, more than 40,000 registrants, and more than 140 conference sessions on robotics, machine vision, artificial intelligence and other industrial automation topics. Some of the machine vision developments follow.

G3, announced in 2009, is the global coordination of machine vision standardization, where industry standards groups agree to promote each other’s standards, not overlap other associations’ standards, jointly organize international vision standards meetings twice a year in Asia, Europe and USA, and jointly organize standards demonstration booths at major vision shows. Education and outreach include a plug fest and a brochure of G3 standards on camera interface, camera performance, lens mount, lighting, Industry 4.0 and system integration.

A3 machine vision standards: Camera Link HS, GigE vision

Bob McCurrach, director of vision standards for the Association for Advancing Automation (A3), talked about the benefits of Camera Link HS, which has copper and fiber interfaces, IP core with a low price, and is the fastest interface. V1.2 was released in fall 2022. V1.3 is in progress, including addition of more bootstrap registers for self-describing data interpretation on multi-connectors with data lanes targeting sensors with complex read-out schemes. A faster line rate is underway, pending minor specification changes, field-programmable gate array (FPGA) chips and optical engines.

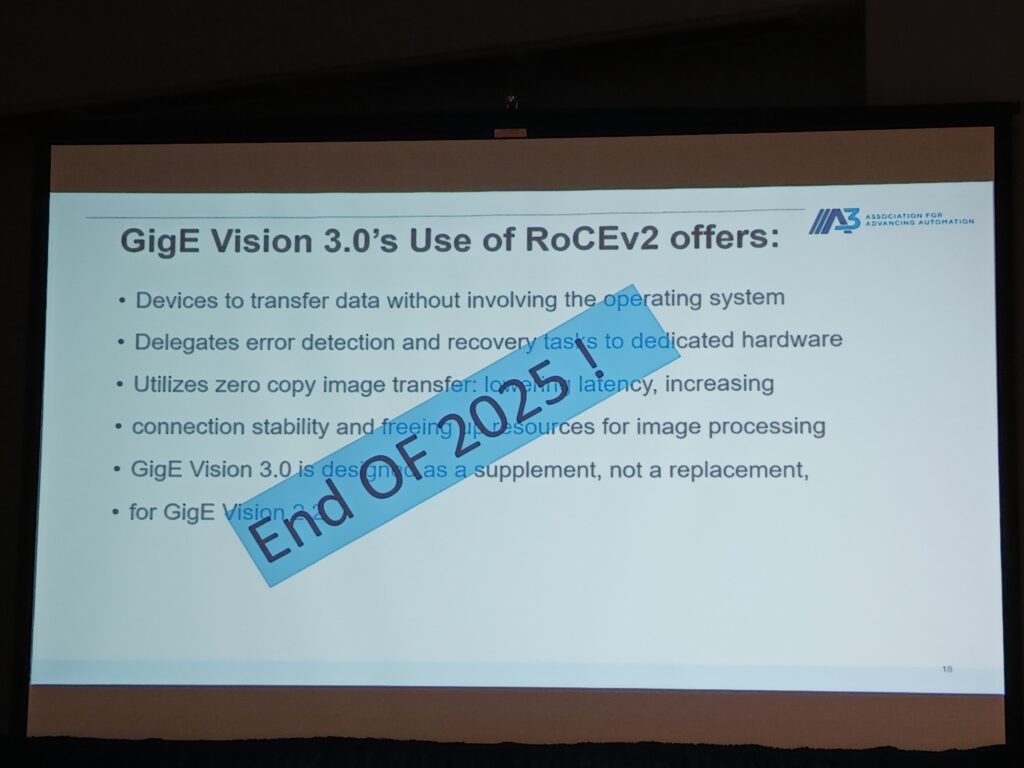

GigE vision benefits were discussed, including long reach, up to 100 meters without regeneration and farther with switches or using fiber. High bandwidth, low cost, and network flexibility also are available.

GigE Vision 3.0’s use of RoCEv2 is designed to supplement GigE Vision 2.2. RoCEv2 is remote direct memory access (RDMA) over converged Ethernet version 2. GigE Vision 3.0 offers devices to tranfer data without involving the operating system, delegates error detection and recover tasks to dedicated hardware and uses zero copy image transfer.

USB3 Vision specification, at version 1.2, implements GenCP, GeniCam, SFNC and most recently, GenDC. It supports USB speeds up to USB4. It typically uses a one-cable solution, providing power control and streaming and benefits from the USB- Type-C ecosystem, which allows higher power and bandwidth is said to offer better usability and robustness than traditional Type-A/B connectors. At the highest speed, it has extremely low CPU usage (zero copy operation). Cables include electrical, optical and hybrid, including power. The test suite allows for robust device verification. New this year is compliance for USB cable extenders. A working group’s focus is testing and verification. New cameras have silicon for higher speed USB 10…20Gbit are in development.

EMVA machine vision update: ISO-24942, GeniCam

Werner Feith of the European Machine Vision Association (EMVA) said ISO-24942 (EMVA 1288) measures camera and image sensor quality. (EMVA 1288 was promoted to ISO level in October 2024 and was said to be the first machine vision standard to be accepted as an international standard.) The standard is handled in Working Group 28 “Machine Vision” within Technical Committee 42 “Photography.”

ISO TC42 WG28 started with EMVA1288 V4.1 (the unified version). EMVA offers certification as an EMVA 1288 expert.

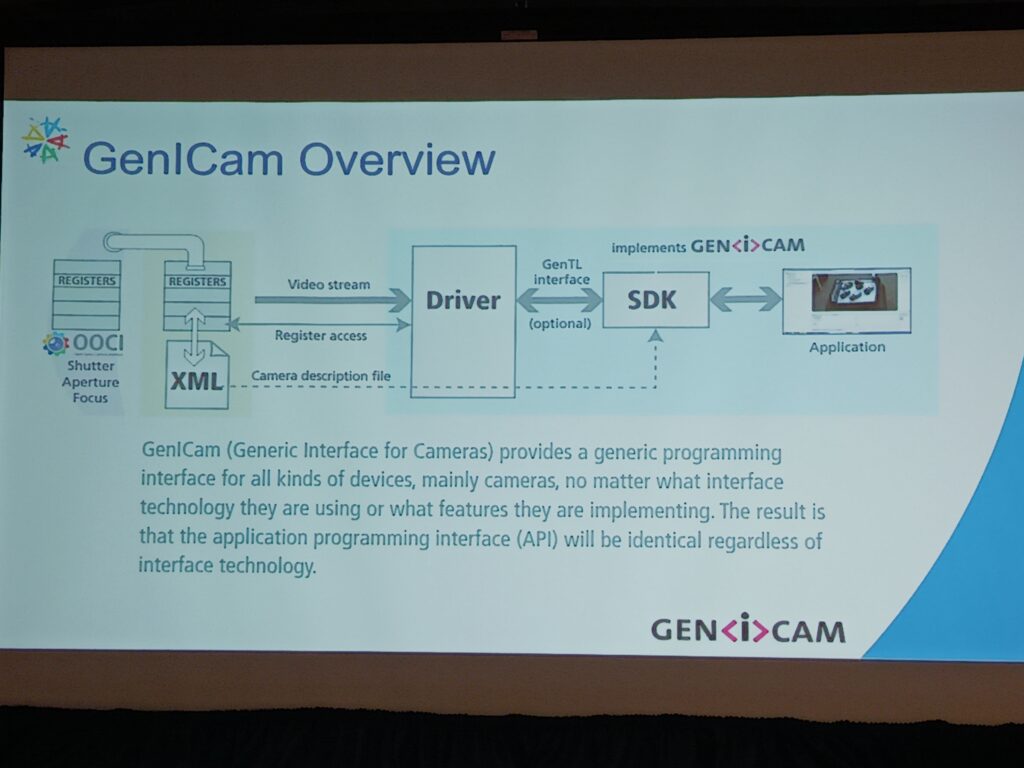

GeniCam (Generic Interface for Cameras) provides a generic programming interface independent from interface technology or features of the connected device (or camera). The result is that the application programming interface (API) will be identical regardless of interface technology.

The GeniCam software interface standard is used by all G3 hardware interface standards: A3 Camera Link and Camera Link HS, GigE Vision and USB3 Vision; JIIA CoaXPress; and EMVA Open Optics Camera Interface (OOCI).

GeniCam device validation promotes consistent adoption of GenApi and the Standard Features Naming Convention (SFNC). It is already used in GigE Vision and CoaXPress Validation. Additional work planned is to make the existing specification more user friendly and to add a specification for persistence.

JIIA standards update: CoaXpress, SLVS-EC

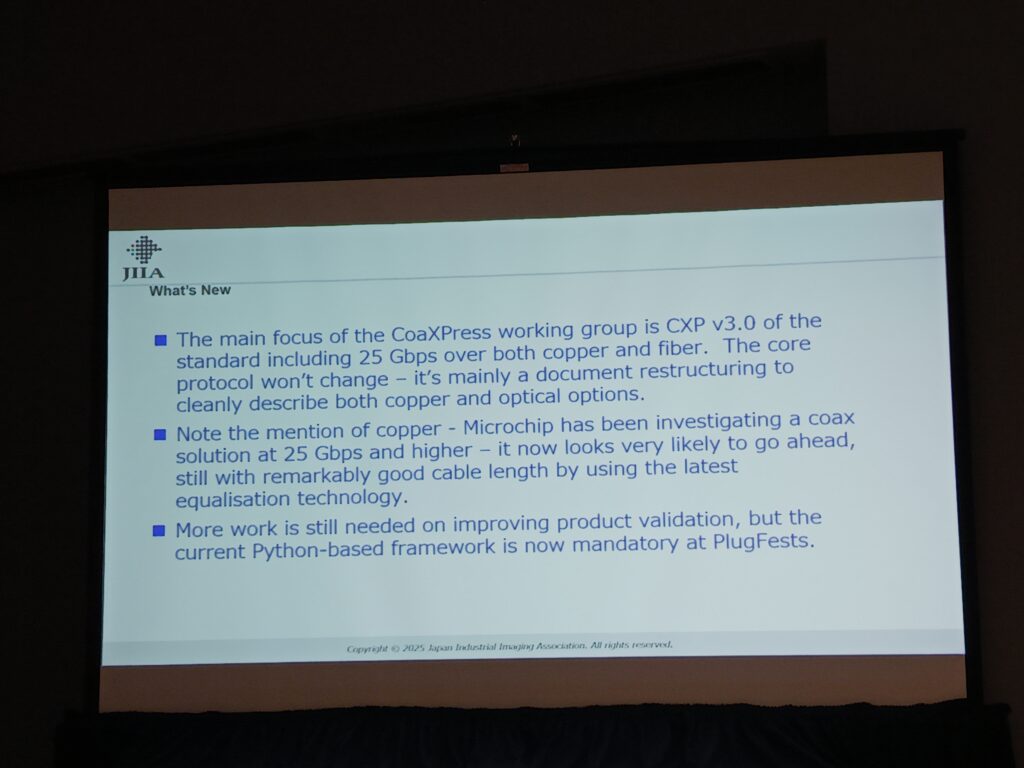

Masahito Watanabe, Japan Industrial Imaging Association (JIIA) chairman, said the CoaXPress working group, CXP v3.0, covers 25 Gbps over copper and fiber. The core protocol won’t change; a document restructuring more cleanly describes copper and fiber options. Microchip has been investigating coax for 25 Gbps and higher, that seems likely to go ahead with “good cable length by using the latest equalization technology.” More work is needed on product validation; the current Python-based framework is mandatory at plug fest meetings. Links to suppliers are available at www.coaxpress.com.

The Scalable Low Voltage Signaling with Embedded Clock (SLVS-EC) standard is a high-speed interface between image sensor and processor (FPGA, SoC, etc.). It’s said to offer high speed (up to 12.5 GBPS/lane) with multi-lane function, easy assembly and simplified protocol.

The Optical Transmission Media JIAA subcommittee restarted in February and will discuss aligning with A3 and other standards. Work includes an A3 small optical connector discussion for use in CameraLink HS, CoaXPress and GigEVision.

JIIA connector and cable certification system is underway to ensure compliance with machine vision standards. It’s based on an assumption that vibration can worsen jitter. Target cable and connected are the CXP12 cable with HD BNC connector after interviews with nine companies that make robots, mounting machines and camera manufacturers.

No update was offered for lighting.

A GeniCam implementation workshop for peripheral devices was conducted. It suggested a possible collaboration between motion and machine-vision devices.

Seven JIIA lens mounting standards were listed: LE-001 through LE-007, 2012 through 2024, covering machine vision cameras and mechanical interfaces. The JIIA Lens Working Group aims to externally control lenses for machine vision applications integrated with cameras. Study of the LensConnect technology from CBC Co. for external control of lenses is underway.

IIDC 2 version 1.2.0 has been released, and the related working group is gathering ideas for version 1.3. Ideas include possible transport layer for CoaXPress, optical device control OpticControl. It also includes a review of unused specifications and functions.

VDMA machine vision standards update

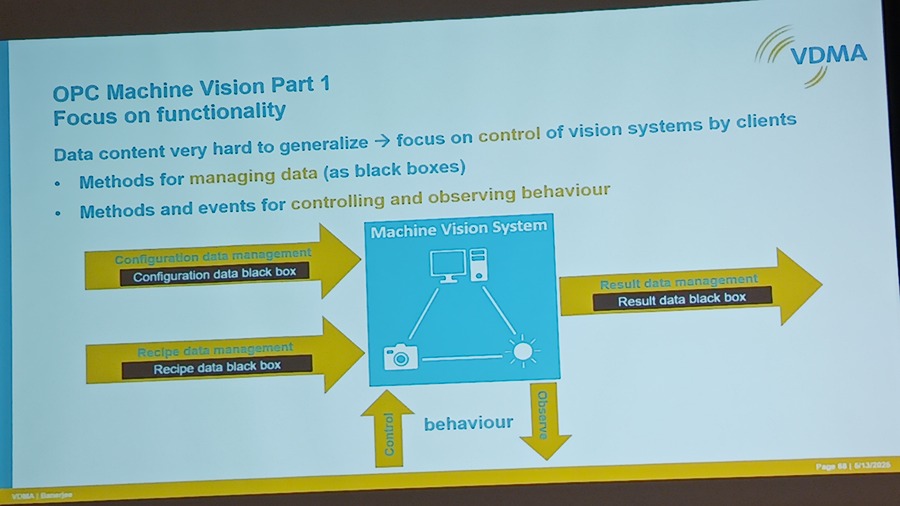

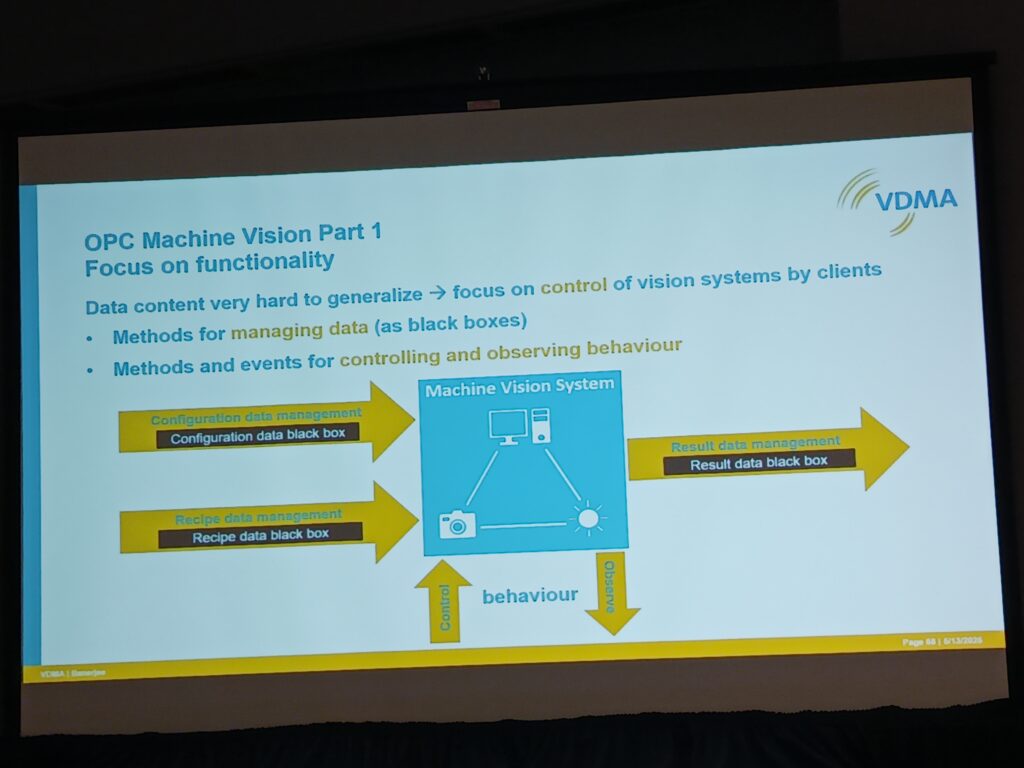

Suprateek Banerjee, German Engineering Federation (VDMA) standards manager, began with discussion of OPC UA as aa building block for Industry 4.0 efforts, as a platform-independent interoperability standard for secure and reliable exchange of data and information for industrial automation and other industries. By using OPC UA companion specification so each device provides the same model with reduced engineering efforts. About 60 VDMA companies are involved with a core working group of 17 companies, many automation providers. The OPC Machine Vision initiative hopes to help with the broad variety of devices, systems, applications, results and time behaviors creating vast potential for misunderstandings.

OPC Machine Vision initiative part 1 focuses on control of machine vision systems by clients to manage and control behaviors. OPC Machine Vision initiative Part 2, released in April 2024, demonstrates a umati dashboard, and next steps include preparation of test cases for certification and coordination with OPC Robotics.

VDI/VDE/VDMA 2632 aims to provide a common understanding of machine vision systems for communication between providers and customers/users to avoid communication problems during planning, implementation and acceptance tests.

Mark T. Hoske is editor-in-chief, Control Engineering, WTWH Media, [email protected].

Keywords

Industrial machine vision standards, global standard harmonization

Consider This

How are you improving machine vision technologies?

You also might like

For more about machine vision, see the Control Engineering Machine Vision eBook at www.controleng.com/ebook

And https://www.controleng.com/mechatronics/vision-and-discrete-sensors