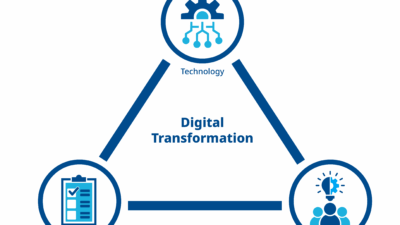

Digital Transformation

Digital transformation in manufacturing refers to the use of digital technologies to improve and transform manufacturing processes, supply chain management and the overall operation of a manufacturing business. Digital transformation involves the integration of digital technologies, such as the internet of things (IoT), artificial intelligence (AI) and big data analytics, into the manufacturing process to improve efficiency, increase productivity and reduce costs. Examples of digital transformation in manufacturing include robotics and other automation, supply chain optimization, predictive maintenance and product customization. Digital transformation in manufacturing aims to improve efficiency, increase productivity and reduce costs, leading to increased competitiveness in the market.