What’s next for industrialization as the industry begins to prepare for Industry 5.0.

Engineers play a critical role in integrating legacy systems into the digital landscape of today’s businesses. The new-age enterprises thrive on technologies such as artificial intelligence (AI) and machine learning (ML), Big Data and analytics, and robotic process automation (RPA). To optimize these technologies, organizations need to either overhaul their operations completely or make use of the existing setup and intelligently transform them as per the business needs. This makes strategizing a very important gamut of the digital transformation exercise.

A complete overhaul is not only cost-intensive but also risks compromising business continuity. As a result, organizations generally opt for the latter option and gradually transition legacy systems while keeping a close look at the lifecycle.

Progress of industrialization

Industrialization has seen various remarkable and future-defining changes over the past few centuries. Going from swift mechanization to electrification to seamless use of information technology (IT), the first three phases of industrialization ensured rapid evolution of businesses. With the advent of the fourth industrial revolution, more commonly known as Industry 4.0, operations started getting digitized and organizations across the spectrum felt the need for digital transformation.

Industry 5.0 is on the horizon. The success of digital transformation, coupled with the advancements in the Internet of Things (IoT) and high-speed, low-latency connectivity will define the future of work.

With digitization taking center stage, engineering solutions have grown in impetus and scope. The prospects for engineering services look especially promising as the global market for Industry 4.0 sees an upsurge. The projected value of the market is $21.7 billion by 2023, up from $7.7 billion in 2018. Rapid advancements of engineering applications and solutions will drive the market to grow almost threefold and at a compound annual growth rate (CAGR) of 23.1% between 2018 and 2023.

Keeping pace with evolution

There is an increase in investment, especially in the industrial, logistic and commercial infrastructure. While Industry 4.0 is the undercurrent of this expected rise in demand for engineering, 91% of businesses are struggling to achieve the digital transformation essential to survive and thrive in this era.

One of the main contemporary challenges being faced by organizations in their digital transformation pursuit is the integration of legacy systems. However, it is important to find opportunities in every challenge and legacy systems are no exceptions.

Making legacy systems into smart systems

Engineering applications are vital because legacy systems don’t possess the required capabilities for a smart process. The use of sensors is critical to vitalizing legacy systems and integrating them into the digital ecosystem. Given the significance of data and real-time analysis, these sensors help in channelizing important information on performance, productivity and the legacy machines’ health.

In a smart paradigm that depends on immediate communication across multiple devices, sensors provide visibility to all relevant stakeholders at any given time. Real-time insights derived from the data transmitted by the sensors also enable spontaneous and informed decision making. Finally, thanks to these engineering applications, predictive maintenance of the legacy systems is made possible on the basis of health diagnoses.

Collaboration with agile machines

Matured technologies have laid the foundation for digital transformation of operations, and emergent technologies are expediting the process with the aim of digitizing operations at scale. Progress at a breakneck pace is driven by intelligent machines. These machines will rely less on human interventions and will be free from the shortcomings of their predecessors. At the bottom of this endeavor lies the ambition of a collaborative, agile future of work will thrive on human-machine synergy, and new-age, future-facing engineering applications will be key enablers.

Making legacy systems future ready depends on key decisions. First and foremost, a thorough understanding of the needs will dictate the most appropriate digital strategy. As the business plan will rely on the digital strategy, it is important to align it with short-, medium-, and long-term goals. Once the strategy is in place, the right engineering applications will determine the success of the overall digital transformation experience.

Size digital transformation to fit

Digital transformation initiatives across industries have shown that one size doesn’t fit all, and instead, the approach has to be horses-for-courses. For instance, enterprise resource planning (ERP) systems can help integrate machines and processes, but they are not the best bet when it comes to long-term, future-proof changes.

Organizations embarking on digital transformation often end up biting more than they can chew by entrusting IT teams with the responsibility of writing, testing and deploying in-house integration solutions. While such decisions are brave, the cost, time and risk they entail make them not worth making. This hastiness is detrimental as it can completely derail the initiative before it is initiated.

In the end, the most important aspect of digital transformation is ensuring timely changes in small installments. Data plays a crucial role in bringing every element of the process up to pace, and it is therefore paramount for organizations to create a robust and holistic database, accumulating data from every single end point.

In a digital landscape strewn with smart devices, every bit of data collected by engineering applications from various ERP, customer relationship management (CRM), product lifecycle management (PLM), and supply chain management (SCM) systems is critical. The idea should lead to making incremental changes without putting massive pressure on either IT or operations technology (OT).

Agile automation with human involvement

For the process to be agile, humans too have a crucial role to play. Radical changes are bound to attract resistance and cynicism, especially when machines tend to become more autonomous. However, it is important that company leaderships take the onus of making the human workforce aware of the purpose of digitization and how it can benefit everyone. In essence, digital transformation is as much about business progress as it is about easing human lives. The cultural change has to be the bedrock for initiatives such as size, scale and scope.

Digital transformation will make machines smarter and vitalize human skills by using them in more critical and perspective-driven jobs. Human-machine synergy is pivotal to the scoping of tasks and thereby increasing overall productivity across enterprises.

The future has arrived. Are we ready for digital transformation?

Narayanan Ramanathan is global head of digital engineering, L&T Technology Services Ltd., a CFE Media content partner. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media, [email protected].

MORE INSIGHTS

KEYWORDS: Engineering future, digital transformation

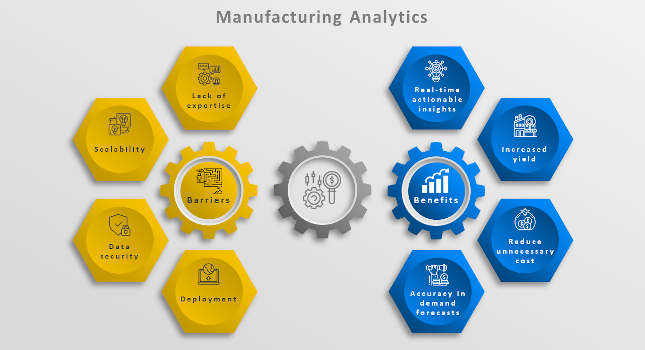

Digital transformation provides manufacturing benefits.

Legacy systems can give way to smart systems.

Human-machine synergies help with size, scale and scope of digital transformation.

CONSIDER THIS

How’s your digital transformation going? Do you see humans and machine increasing synergy?