How AI is challenging traditional assumptions in process control and unlocking new value from plant data.

AI in industrial process modeling insights

- Traditional process modeling is limited by its reliance on linear assumptions, simplified gain matrices and short-duration step tests that often fail to capture the full complexity and dynamics of real-world industrial processes.

- AI-based optimization (AIO) offers a paradigm shift by using large volumes of historical plant data and deep learning to model nonlinear, multivariable interactions — revealing insights and optimization opportunities that traditional APC methods miss.

- Trust and explainability are critical for adoption, as successful implementation of AIO depends not only on technical performance but also on building confidence among operators through tools like what-if simulations and collaborative validation with domain experts.

Understanding industrial process modeling

Industrial process modeling lies at the heart of modern optimization in the complex process industries. It seeks to describe how a large number of process variables interact — often in nonlinear, dynamic and site-specific ways — to enable operators to move toward optimal operating states. From a mathematical perspective, this entails solving a multivariable optimization problem in a multi-dimensional solution space.

To make this tractable, traditional approaches simplify the system by evaluating two-variable relationships — defining “gains” between independent and dependent variables. For example, increasing the overhead temperature on a distillation column typically results in more heavy components in the overhead product, a positive gain. These expected relationships, grounded in first principles and taught using theory-based tools like McCabe-Thiele diagrams, serve as the building blocks of traditional model-based control systems.

In practice, these gain relationships are codified into gain matrices. They allow control engineers to predict how outputs will respond to input changes. If observed plant behavior deviates from textbook expectations — due to noise, dynamic delays or unexpected process interactions — the model is typically adjusted or simplified to maintain internal consistency. In this framework, step tests are used to generate a single gain value over a steady-state interval, often limited to a few weeks of data collection. As a result, the models are inherently linear, time-limited and coarse approximations of reality.

APC vs. AIO: A paradigm shift in modeling

Advanced process control (APC) tools have served the industry well for decades, but they face critical limitations, such as:

- Linearity assumption: APC relies on static gain matrices derived from step tests, assuming linear relationships even in processes known to be nonlinear.

- Limited training data: Step tests are typically run over 1–2 weeks, capturing only a narrow window of plant behavior.

- Delayed first-principles application: Traditional modeling first fits observed data into expected relationships, excluding dynamics that don’t align with those expectations.

An AI-based model-building methodology flips this approach. Rather than beginning with assumptions, closed loop AI optimization (AIO) begins with plant data — months to years of minute-by-minute operating history — and applies deep learning to discover true operational relationships. These deep neural networks specialize in providing the capacity to represent relationships that linear models struggle to express. Importantly, first principles guardrails can be incorporated in AI-based model building, but as a second step where domain experts use their knowledge to interpret and validate the results. Letting the neural networks run outside of the confines of first principles at the start of the model-building process removes unnecessary assumptions and bias and allows the models to uncover unexpected, but valid relationships.

This shift in the order of operations is profound. It enables the model to uncover interactions missed by traditional modeling and adapt to nonlinearity, multivariable coupling and previously unmeasured effects. While APC simplifies complexity to fit within linear structures, AIO embraces complexity to unlock greater insight.

Critically, AIO models need not be thought of as “black boxes.” Engineering judgment plays a central role — through client collaboration, gain matrix expectation-setting and domain expert review — ensuring that AI-based models remain grounded in physical understanding and site-specific realities.

Case Study: Hydrocracker Optimization and Unexpected Gains

Challenge:

Conversion units such as FCCs, hydrocrackers and other multi-product stream reactors present challenges to traditional linear process control and optimization methods, which make them great candidates for an AI-based approach. The closed loop AI optimization (AIO) approach was put to the test to optimize a notoriously finicky hydrocracking unit. The goal was to analyze the impact of changes in weighted average bed temperature (WABT) on product yields. A challenging problem to solve under any circumstances, this particular hydrocracker presented additional hurdles due to the quality of the historical data. The major data quality issues faced were:

- Data compression: To conserve storage, the site had employed compression in its historian system, which interpolated values and omitted intermediate readings within a specified tolerance of the previous sample. This omitted and interpolated data can obscure the dynamic responses critical for accurate modeling. At today’s data storage cost, it is a best practice to turn off compression settings to avoid running into limitations due to a previous decade’s storage strategy.

- Lack of cut point corrections: Product flows from the hydrocracker’s downstream distillation columns weren’t corrected for cut point variations, limiting the fidelity of yield predictions.

Despite these limitations, the AI model was expected to reveal a nonlinear gain between WABT and diesel yield — consistent with the well-documented over-cracking phenomenon. Initially, diesel yield increases with rising WABT due to enhanced conversion of heavy hydrocarbons. But beyond a threshold, diesel molecules themselves crack into lighter, less valuable LPG products (e.g., butane, propane, ethane). Traditional APC models avoid operating near this inflection point due to linear assumptions breaking down, which could push the unit into an unfavorable economic regime.

An AIO model, by contrast, would identify and safely navigate this nonlinearity, continuously locating the global optimum — even near operational limits.

For this client’s case, however, the AIO model output defied expectations. All product gains with respect to WABT appeared positive, with no visible inflection. Further investigation revealed that this was not a modeling flaw, but a reflection of data limitations — particularly the lack of cut point correction and insufficient temporal resolution due to compression.

Solution: Creativity in the face of constraint

While the model wasn’t suitable for closed-loop control in the initial, data-limited form, it still demonstrated value. Visualization of the gain distributions identified optimization opportunities missed by conventional control. To make this actionable, profitability-based variables tied to historical pricing regimes were introduced to the model.

Consider two pricing scenarios:

- When diesel commanded a premium over jet fuel

- When the reverse held true

By segmenting historical data by price regime, the model revealed distinct optimum strategies. For example, under a diesel-favored regime, the predictor model showed that existing operations inadvertently increased jet production at diesel’s expense — an opportunity loss caused by static operating targets.

In facilities where pricing, demand or constraints change frequently, real-time optimization can be a game changer. A closed loop AI optimization (AIO) solution issuing new set points every 5–10 minutes — rather than relying on static weekly plans — can adapt instantly to market shifts, unplanned outages or competitor behavior. This agility translates directly into multi-million-dollar annual profitability improvements.

AIO solution success dependent upon trust

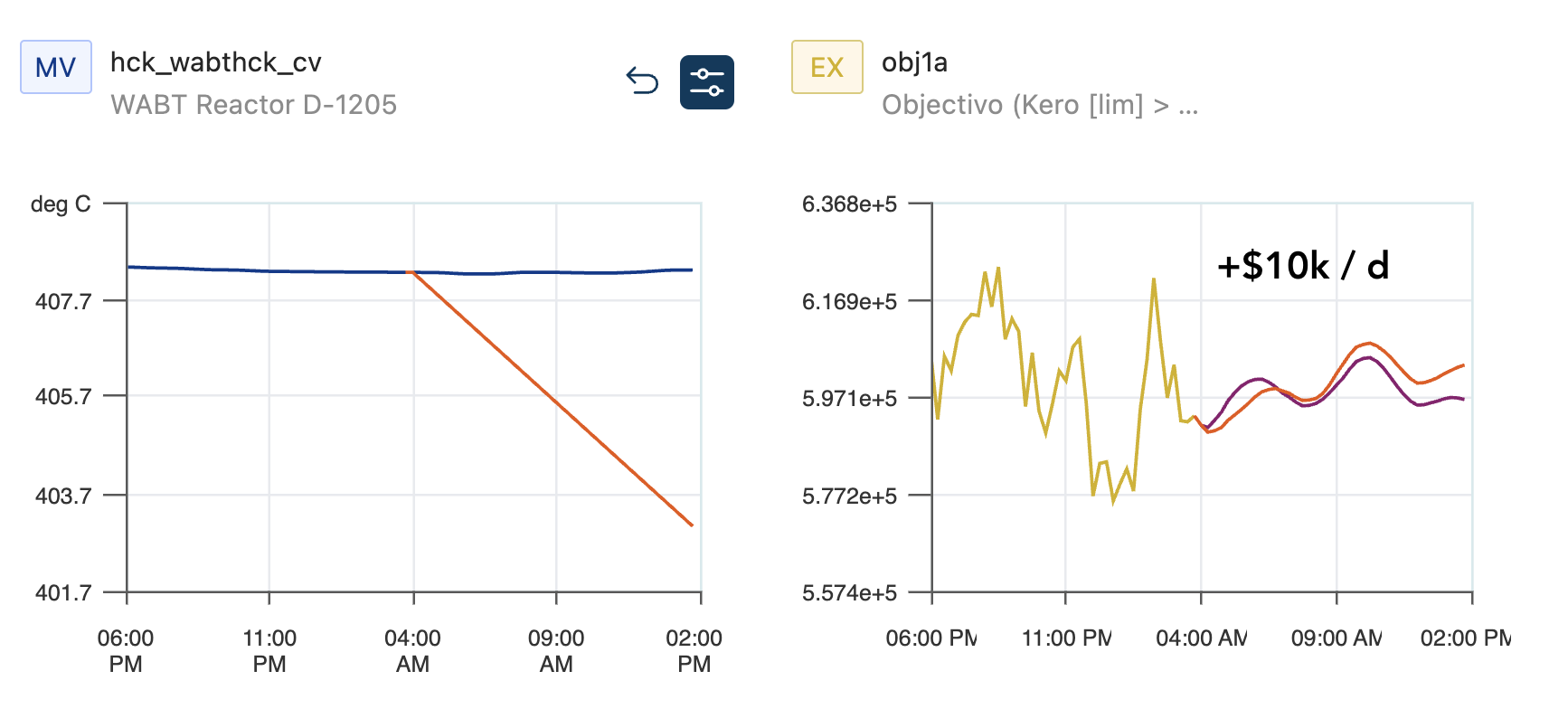

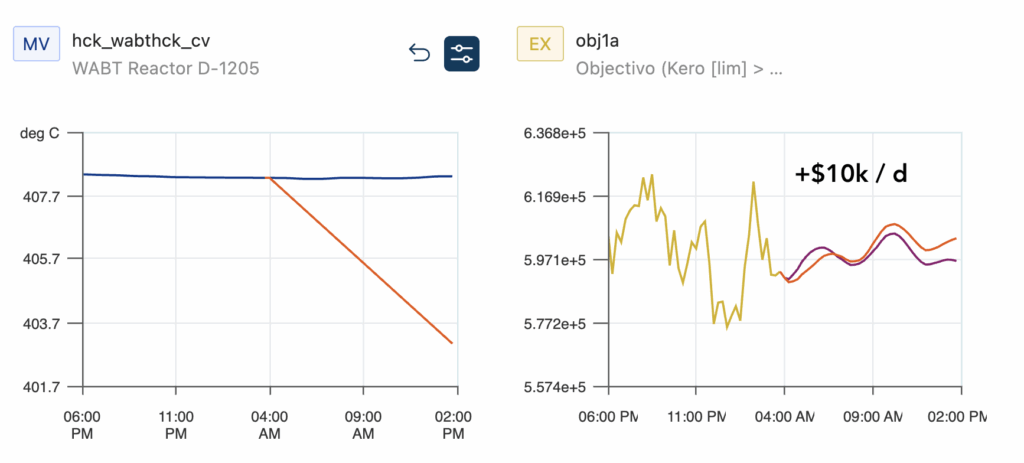

As the primary interface with process control systems, plant operators are a key ingredient in the success of any closed-loop optimization solution. Building their trust is paramount to them keeping the solution engaged rather than turning it off and resorting to the status quo. Since AI-based solutions are more complex mathematically to explain than first principles or laws of physics, it’s important to include explainability tools, such as what-if simulation capability, so that operators can play around with the models, simulating different scenarios and testing them against their experiences. In figure 1, a manipulation to lower reactor WABT shows that reducing the reactor WABT had a positive impact on the unit objective function resulting in a margin gain of ~$10k/day. By simulating manipulated and disturbance variable moves, shifting constraints and switching up price sets, operators on this hydrocracker built up trust in the AIO models.

Figure 1: Operators and engineers perform what-if simulations to build trust in AIO models. A manipulation (orange) shows that lowering WABT has a $10k/d increase on the objective function.

Embracing data without abandoning fundamentals

AIO models like the one described in the case study above don’t replace engineering insight — but, rather, they amplify it. Comparing expected gain matrices with those learned from plant data provokes experts to challenge assumptions, quantify deviations and uncover untapped opportunities. This tension between expectation and reality is not a weakness — it’s a strength, and it’s where innovation lives.

As the industry continues to digitalize, the fusion of first-principles thinking with data-first AI modeling will become the standard for solving previously intractable optimization challenges. The result? Heavy process industries like refining and petrochemicals can expect smarter, faster and more profitable decision-making and action across the plant.

AUTHOR

Greg White is a business consulting engineer at Imubit, where he works with clients to identify and implement high-value applications of artificial intelligence optimization (AIO) in refining and chemical manufacturing. He received a B.S. in chemical engineering from the University of California, Santa Barbara, with a minor in Spanish literature. At Imubit, Greg combines deep technical expertise with a consultative mindset to help operators and engineers harness the power of AI-based optimization tools.

LEARNING OBJECTIVES

- Understand the limitations of traditional process modeling and advanced process control (APC) — particularly the reliance on linear assumptions, simplified gain matrices and narrow data windows.

- Learn how AI-based optimization (AIO) uses deep learning and historical plant data to model complex, nonlinear interactions and uncover previously hidden optimization opportunities.

- Recognize the importance of operator trust and explainability tools in the successful implementation of AI-driven models within industrial control environments.

CONSIDER THIS

How much untapped value might exist in your plant’s historical data, and are traditional modeling methods leaving optimization opportunities on the table that AI-based approaches could uncover?