Constant temperature and power anemometry advances in flow measurement technology are allowing process engineers to do more than ever before with process instrumentation.

Learning Objectives

- Flow measurement technology helps process engineers get better results in harsh environments.

- One technology advance is constant temperature anemometry.

- Another advance is constant power anemometry.

Flow measurement technology has gone through many changes and advances over the past several years. Flowmeter and flow sensors help engineers in process applications in many ways and can operate in hazardous or dangerous conditions that weren’t possible before.

Two thermal mass flowmeter advances

Thermal mass flow technology is evolving and removing some earlier challenges. Thermal mass flow deploys mainly two design working principles:

1. Constant temperature anemometry

The constant-temperature sensor design maintains a constant temperature differential between a heated sensor and a reference sensor; the amount of power required to maintain the differential is measured as an indication of the mass flow rate. Constant-temperature thermal mass flowmeter features include:

- High-frequency response

- The low electronic noise level Immunity from sensor burnout when airflow suddenly drops

- High rangeability

- Compatible with various resistance temperature detector (RTD) sensors, such as hot thin film, wire wound, etc.

- Applicability to gas flows.

2. Constant power anemometry

Constant power sensor design maintains constant power between two temperature sensors, which will provide a flow rate proportional to the temperature of the gas flows. This design is less popular and has very limited usage due to technical limitations such as:

- Passive, no feedback mechanism for any correction

- No zero-flow stability

- Slow temperature and velocity response

- Limited temperature compensation.

Thermal mass flowmeter measurement technology is gaining respect in gas mass flow rate measurement in various applications ranging from very low flow rates to ultra-high flow rates accurately. Thermal mass flow measurement is realized in different ways and flowmeter types for satisfying different industrial needs such as:

- Laboratory style (with bypass principle) for analytical and research purposes

- Inline industrial style for intermediate pipe sizes from 15 to 150mm

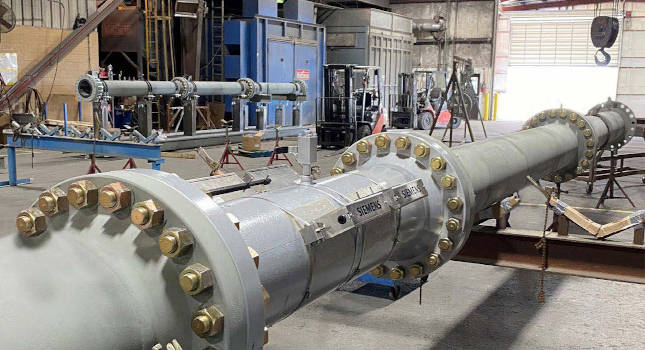

- Insertion style for larger pipe sizes.

Today’s process industries demand measurement technologies which are fairly priced and will help in optimizing process efficiency for reducing environmental emissions. To meet such demand, the manufacturers are focusing on the research and development of thermal mass flow sensor technology and application expectations against other technologies.

For harsh applications customized insertion thermal mass sensors are available. Process gases stack emissions are corrosive. Chemical industries have to follow emission norms and measure the flow for this. It is impossible to measure the flow with conventional technologies. This has many challenges in measurement such as material compatibility and cost of ownership.

Other mass flow sensor advancement includes solutions for hot application with corrosive fumes, unknown waste-gas and gas traces in large duct with low-pressure gas mass flow measurement.

Manish Patel, director, Leomi Instruments Pvt. Ltd. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].

Keywords: thermal flowmeter, flow measurement, process instrumentation

CONSIDER THIS

What advances do you need in flow measurement technology?