How are programmable logic controllers (PLCs) and industrial PCs (IPCs), embedded controllers, programmable automation controllers (PACs), smart input/output (I/O) modules, other logic devices and related software helping Industrial Internet of Things (IIoT) promises envisioned? A webcast investigates.

Learning Objectives

- Examine how industrial logic devices such as PLCs, IPCs, embedded controllers, PACs, smart IO modules, combination controller/human-machine interfaces and others have adapted to the needs of Industrial Internet of Things (IIoT), Industry 4.0 and smart manufacturing initiatives.

- Review often-used terms, such as scalability, programming flexibility and interoperability, as they relate to industrial controllers.

- Determine what to look for in a PLC, IPC, or other controller to match application needs and why and how cybersecurity matters.

Industrial Internet of Things (IIoT), Industry 4.0 and smart manufacturing concepts are familiar to architects of industrial automation and controls. How are programmable logic controllers (PLCs) and industrial PCs (IPCs), embedded controllers, programmable automation controllers (PACs), smart input/output (I/O) modules, other logic devices and related software helping IIoT promises envisioned? If an application needs a controller, what kind should be considered and why? Does IIoT imply cybersecurity and interoperability, or are those separate considerations? What about scalability and growth versus a “set it and forget it” design? Are you asking the right questions? Will you have the right answers when someone else asks?

Kevin Gibson, senior controls engineer, Applied Manufacturing Technologies (AMT) and L. John Shipley, PE, CAP, director of Indiana operations, senior electrical engineer, Patti Engineering, provide answers in a Nov. 11 Control Engineering webcast, “PLCs and other controllers in an IIoT world,” archived for a year, thereafter. An RCEP professional development hour is available. The webcast learning objectives are to:

- Examine how industrial logic devices such as PLCs, IPCs, embedded controllers, PACs, smart I/O modules, combination controller/human-machine interfaces (HMIs) and others have adapted to the needs of IIoT, Industry 4.0 and smart manufacturing initiatives.

- Review often-used terms, such as scalability, programming flexibility and interoperability, as they relate to industrial controllers.

- Determine what to look for in a PLC, IPC or other controllers to match application needs.

- Learn cybersecurity considerations of industrial controllers.

- See how applications and lesson-learned examples can help with controller selection.

PLCs, then and now

Controllers of today have adapted to new needs, Shipley said. In the past, PLCs:

- Were designed to replace relay panels and the fixed wiring of relay logic.

- Had limited memory and had to be expanded by adding modules.

- Started to be networked, over time, through serial communication networks such as RS-232C, RS-422, RS-485.

As needs to control more sophisticated equipment arose, more powerful communication protocols based on Ethernet were developed, and today, PLCs have:

- Significantly more onboard memory.

- More commands to enable more control functions.

- More programming language options (IEC 61131-3)

- More communication protocol options.

- More communication resource options.

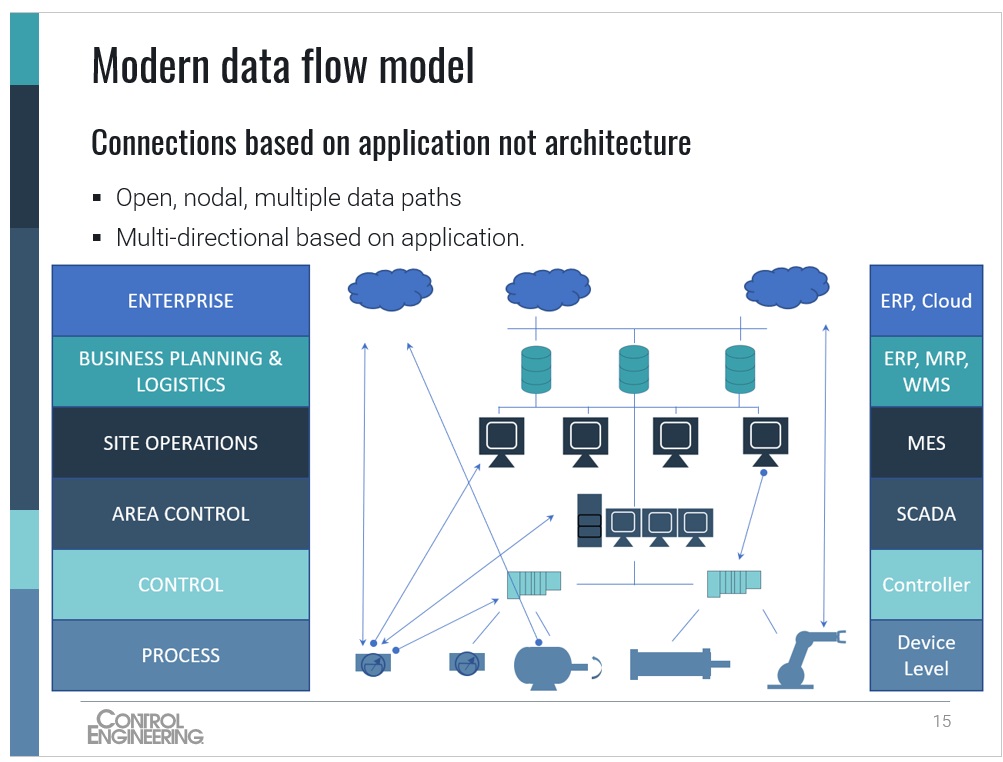

Controller considerations include interoperability, network architecture

Today, in addition to cybersecurity, application requirements include interoperability and network architecture consideration, Gibson said. These include:

- Ease of exposing data to consumers (interfaces/connections/protocols)

- 5G/wireless protocols

- Wired infrastructure

- Data aggregation via I/O block or controller

- Connection issue diagnosis

- Ease of consuming, storing, processing this data

- Identify individual device

- Identify data fields, types

- Refresh speeds.

Much more on these topics is available in the 1-hour webcast and question-and-answer session.

Kevin Gibson, senior controls engineer, Applied Manufacturing Technologies (AMT) and L. John Shipley, PE, CAP, director of Indiana operations, senior electrical engineer, Patti Engineering; edited by Mark T. Hoske, content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: Controllers, PLCs, IIoT, Industry 4.0

CONSIDER THIS

Are you considering a controller upgrade to with more modern smart manufacturing architectures?