Single-Pair Ethernet (SPE) is revolutionizing industrial networking by enabling seamless Ethernet communication over a single twisted-pair cable.

Single-Pair Ethernet insights

- Single-Pair Ethernet (SPE) is a subset of Ethernet designed to operate over a single twisted pair of copper wires, supporting speeds ranging from 10 Mbps to 1 Gbps over distances of up to 1,000 meters.

- By reducing cabling complexity while maintaining high-speed data transfer, SPE helps bridge the gap between traditional fieldbus systems and modern industrial Ethernet networks.

- SPE reduces the exposure of critical devices if implemented with proper security measures.

The evolution of industrial networking has been driven by the need for higher-speed, deterministic and scalable communication. Traditional fieldbus systems are rapidly being replaced by industrial Ethernet, but challenges such as complex cabling, power limitations and environmental complexity persist. Single-Pair Ethernet (SPE) is emerging as a transformative technology that simplifies Ethernet connectivity while enabling seamless integration across industrial environments.

SPE enables full-duplex Ethernet communication over a single twisted pair of copper wires, reducing wiring costs, weight and installation complexity. This advancement is particularly beneficial for applications in process automation, factory automation and industrial IoT (IIoT), where space constraints and long-distance communication are critical considerations.

What is Single-Pair Ethernet (SPE)?

Single-Pair Ethernet (SPE) is a subset of Ethernet designed to operate over a single twisted pair of copper wires, supporting speeds ranging from 10 Mbps to 1 Gbps over distances of up to 1,000 meters, depending on the application. Unlike traditional Ethernet, which typically uses four or two pairs, SPE enables direct device-to-device communication with minimal infrastructure requirements.

Three benefits of SPE in industrial applications

SPE has three distinct benefits in industrial applications. These include:

1. Network simplification and cost reduction

- Reduces cabling requirements by up to 75% compared to traditional Ethernet.

- Lowers installation costs by reducing the need for gateways and complex infrastructure.

2. Extended reach for industrial environments

- SPE’s ability to support up to 1,000 meters surpasses the 100-meter limitation of standard Ethernet.

- Ideal for large industrial sites, such as oil and gas facilities, power plants and smart buildings.

3. Seamless integration with Industrial IoT (IIoT)

- Supports edge computing and real-time monitoring by connecting sensors and actuators directly to Ethernet networks.

- Reduces the need for legacy fieldbus systems while maintaining industrial-grade reliability.

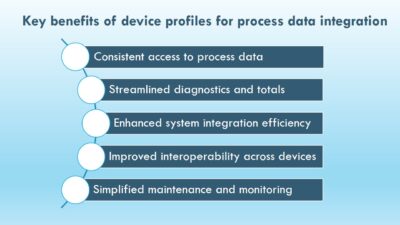

SPE and cybersecurity: Aligning with IEC 62443

While SPE has the potential to facilitate secure practices within an industrial network, it’s not a security mechanism by itself. The correct interpretation is that SPE enables the adoption of better security practices, and its implementation can align with International Society of Automation/International Electrotechnical Commission (ISA/IEC) 62443 when combined with proper security controls.

1. Reduction of attack vectors

SPE enables more efficient network segmentation, helping to reduce the exposure of critical devices if implemented with proper security measures.

2. Enhancement of Access Control

SPE facilitates the convergence to standardized Ethernet networks, allowing the application of network segmentation and secure authentication through appropriate security protocols, aligning with ISA/IEC 62443-3-3 requirements. The standards:

- Define security levels and system security requirements

- Establish technical control system requirements

- Provide best practices for security and a way to assess security performance

- Introduces the concepts of zones and conduits to segment and isolate subsystems

3. Improvement in Anomaly Detection and Monitoring

SPE enables continuous data transmission from industrial devices, making it possible to leverage advanced monitoring and anomaly detection tools, which are essential for ISA/IEC 62443 compliance.

Potential applications of Single-Pair Ethernet in industrial networking

So, what are the potential applications of SPE in industrial networking? The advantages of SPE include:

- Connecting programmable logic controllers (PLCs), robotic arms and sensors with a unified Ethernet network.

- Reducing wiring complexity in smart factories.

- Enabling long-distance communication between remote monitoring stations.

- Enhancing security for critical infrastructure.

- Connecting heating, ventilation and air conditioning (HVAC) systems, lighting controls and security devices over Ethernet.

- Reducing wiring weight in automotive and railway applications.

Challenges and considerations for SPE adoption

It’s clear that SPE has many advantages when it comes to futureproofing industrial networks. However, While SPE offers many advantages, some challenges remain, including:

- Interoperability with existing infrastructure: Transitioning from traditional Ethernet and fieldbus systems requires careful planning.

- Initial investment costs: Upgrading industrial networks to support SPE may involve upfront costs, though long-term savings are expected.

- Security risks: As with any Ethernet-based system, proper cybersecurity measures must be implemented to protect against cyber threats.

SPE as a cost-effective, simple networking solution

Single-Pair Ethernet is revolutionizing industrial networking by providing a cost-effective, simplified and futureproof solution for industrial automation. By reducing cabling complexity, extending Ethernet reach and integrating seamlessly with IIoT, SPE is driving the transition from legacy fieldbus systems to fully connected industrial networks.

Moreover, its alignment with cybersecurity standards like IEC 62443 ensures that industrial environments remain secure while embracing digital transformation. As industries move toward greater connectivity and automation, Single-Pair Ethernet is set to become a foundational technology in industrial networking, bridging the gap between legacy and future-ready systems.

Felipe Sabino Costa, Sc, MBA, PMP, CCNA, CISA-US DHS, is the senior product marketing manager of networking and cybersecurity for Moxa Americas Inc. Edited by Sheri Kasprzak, managing editor, Automation & Controls, WTWH Media, [email protected].