Robot safety: In areas with robotic process automation (RPA), identify and enforce safeguards and practices to mitigate workplace incidents. Heed appropriate standards. Do risk assessments.

In July 1984, an automated die-cast system operator died of cardiorespiratory arrest in a robotic accident. The operator got stuck between a steel safety pole and an industrial robot. The worker was an experienced employee trained on robotics for a week prior to this fatal encounter. It was later found he had entered the operating zone of the robot in an unsafe manner despite training, instructions, and warnings. A presence sensing device in such an application could have potentially averted the incident.

This incident established the need to identify and enforce safeguards and practices to mitigate workplace incidents, especially in robotic process automation (RPA) enabled environments.

Identifying robotic risks

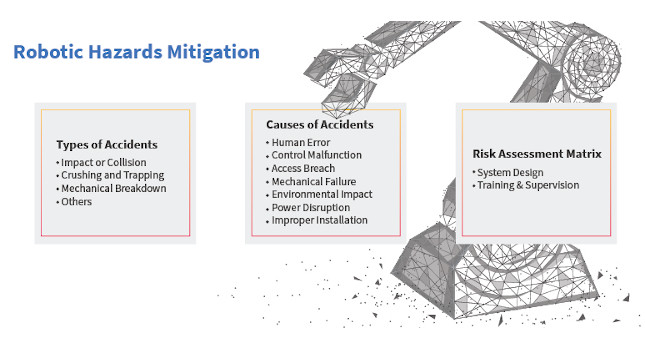

The U.S. Occupational Safety and Health Administration (OSHA) identifies four categories of workplace accidents associated with robotic work cells. All four categories are potentially detrimental to production and compliance. They are:

- Impact or collision accidents: Contact accidents arising from unpredicted arm or equipment movements, malfunctions, or program alterations

- Crushing and trapping accidents: The trapping of a worker’s limb or other body parts between a robotic arm and peripheral equipment (including individuals being driven into such a position and subsequently getting crushed by peripheral equipment)

- Mechanical part accidents: The breakdown of a robot or peripheral equipment that can potentially result in an accident

- Other accidents: From electrical hazards to pressurized fluid hazards, from environmental accidents due to the presence of equipment and cables on the floor, among others.

OSHA: 7 robot-accident sources

Further, according to OSHA, there are seven sources or causes of the accidents mentioned above:

- Human error: Dangerous, unpredicted movement by the robots resulting from human errors in programming and peripheral equipment setup, or insufficient caution due to familiarity with the robotic movements

- Control error: Software malfunction, electromagnetic and radio frequency interference, and faults in control systems and hydraulic, electrical, or pneumatic sub-control systems

- Unauthorized access: The presence of any person within a robot’s operating zone without adequate familiarity with the machine and the caution to be observed around it

- Mechanical failure: Cumulative failure of mechanical parts or unpredictable operations may not be accounted for by the operating programs

- Environmental interference: The external influence on a robotic operation

- Power system fluctuations: Disruptions in power systems that directly communicate with the robotic work cell

- Improper installation: Non-compliance in the installation of a robotic system and its functional testing measures to safeguard against incidents.

Do a robot risk assessment

A comprehensive risk assessment matrix is imperative to contain the potential hazards arising from automated robots. There are several stages for implementing the safeguard protocol in accordance with the robotic safety standard, ANSI/RIA R15.06-1999 (R2009) Industrial Robots and Robot Systems – Safety Requirements, from the Robotic Industries Association and American National Standard Institute.

The National Institute for Occupational Safety and Health (NIOSH) has laid down a set of recommendations and guidance to mitigate risks of incidents on robotics-enabled work floors. These include, but are not limited to, system design and worker training and supervision. Besides, adequate illumination for clear visibility of the operating area and the equipment may sound obvious but is ignored more often than not. Clearly visible signage and floor markings naturally invoke caution in workers.

Robotic system design

The inclusion of gates equipped with electrical interlocks that halt operation when opened are essential for a safe robotic system design. Motion, light, and pressure sensors are integral to detect the presence of a person in a prohibited zone and subsequently stop the operation. Using barriers to halt access to the “pinch points,” which is the area between the robotic equipment and freestanding objects can prevent accidents like the one mentioned in the beginning. The presence of adequate clearance area in and around the operating zone of a robot goes hand in hand with this. Robots typically require more operational space than humans. A thorough study and testing of the robotic equipment is necessary to identify the clearance area.

Remote diagnostic capability and proactive alerting systems are helpful in taking preemptive actions to avert hazards.

Robotic worker training, supervision

Providing adequate and comprehensive training to workers handling and overseeing operations of a robotic system is imperative in ensuring their safety. In this regard, all workers need to be familiarized with the operating mechanism of the robot they will be handling. This has to be a periodic exercise rather than a one-time training. It encompasses motion range, embedded programming, emergency halting mechanism, safety barriers, spatial awareness of all conceivable pinch points, and recommended operating speeds. The presence of workplace safety experts should be mandatory in spite of training sessions, signage and advanced safety technologies.

Robotic safety, productivity

A safe workplace is a productive workplace, it is said. Building a holistic culture of safety and accountability includes taking all prescribed safety measures into account. While technology plays a crucial role in this, it alone is not enough to achieve a zero-hazard (or near-zero-hazard) factory floor. Compliance with industry standards and educating the workforce ensures the best results from the technologies onboard for robotic work floor safety. The abatement of avoidable risks can save human lives and enable modern workplaces to harness the advanced optimal functionality of the robots.

Prasanna Shukla global head of plant engineering practice at L&T Technology Services. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: Industrial robots, robotic risk assessments

OSHA categorizes four types of accidents in robotic work cells.

Robot accident sources, according to OSHA, include human error, control error, unauthorized access and four others.

RIA and NIOSH provide other standards and guidance.

CONSIDER THIS

Robotic efficiency depends on robotic safety.