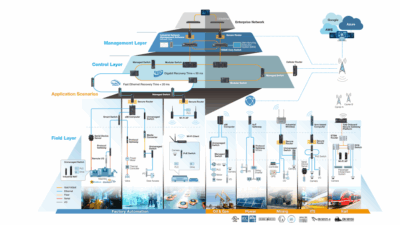

Dodge’s Optify is a condition monitoring platform designed to improve efficiency and reduce costs in industrial operations. The platform combines Dodge Industrial Internet of Things (IIoT) products with data analytics and product expertise. Optify features advanced sensors, breathers, automatic lubricators and gateways, aiming to transform how manufacturers manage operations and help improve operational excellence.

In modern industrial operations, manufacturers are faced with the challenged to minimize downtime, reduce maintenance costs and ensure efficient operations. Traditional methods solely consisting of visual inspection, preventive maintenance, and repairs upon equipment failure are inadequate—leading to unplanned downtime, higher costs, and safety risks.

Cost savings and efficiency gains

A producer of frozen, ready-to-eat meals adopted Optify to tackle its operational challenges. Operating seven production lines required minimizing downtime and enhancing productivity, and Optify’s suite of condition monitoring products, including sensors, automatic lubricators and gateways, helped.

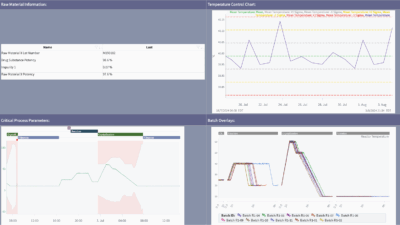

The customer integrated Optify across two production lines, deploying 106 sensors and 23 Dodge Intelli-lube drive units. This setup allowed more effective monitoring and maintenance of bearings, gearboxes and motors in real-time to prevent potential failures while minimizing up-front product investment and annual maintenance costs on grease cartridges.

Since implementing sensor technology, the monitored lines have experienced zero unplanned downtime or lost production. The substantial improvements in efficiency have encouraged the customer to expand use of Optify for its seven production lines.

Sensors provide real-time data to improve decision-making

One of the Optify platform’s key features is its ability to provide real-time data, enabling informed decision-making. The customer leveraged this data to optimize maintenance schedules by identifying potential failures and equipment needing before breakdown occurs. This enabled planned maintenance, reduced downtime and improved equipment efficiency. This data-driven approach helped address potential issues before they lead to downtime, improving reliability.

Edited by Puja Mitra, WTWH Media, for Control Engineering, from a Dodge Industrial news release.