ABB and Vention made it easier for users of the ABB GoFa collaborative robot family to design, operate and maintain ABB GoFa robots, as demonstrated at IMTS 2024.

Collaborative robot do-it-yourself services and support insights

- An online platform enhances use of robotic automation systems through an expanded partnership between ABB and Vention, detailed and demonstrated at IMTS 2024.

- Enhanced collaborative robot abilities include smarter pick and place, with collaborative robot design, operations and support services.

Learning Objectives

-

- Understand how an online platform enhances use of robotic automation systems.

- Learn about enhanced collaborative robot abilities and collaborative robot design, operations and support services.

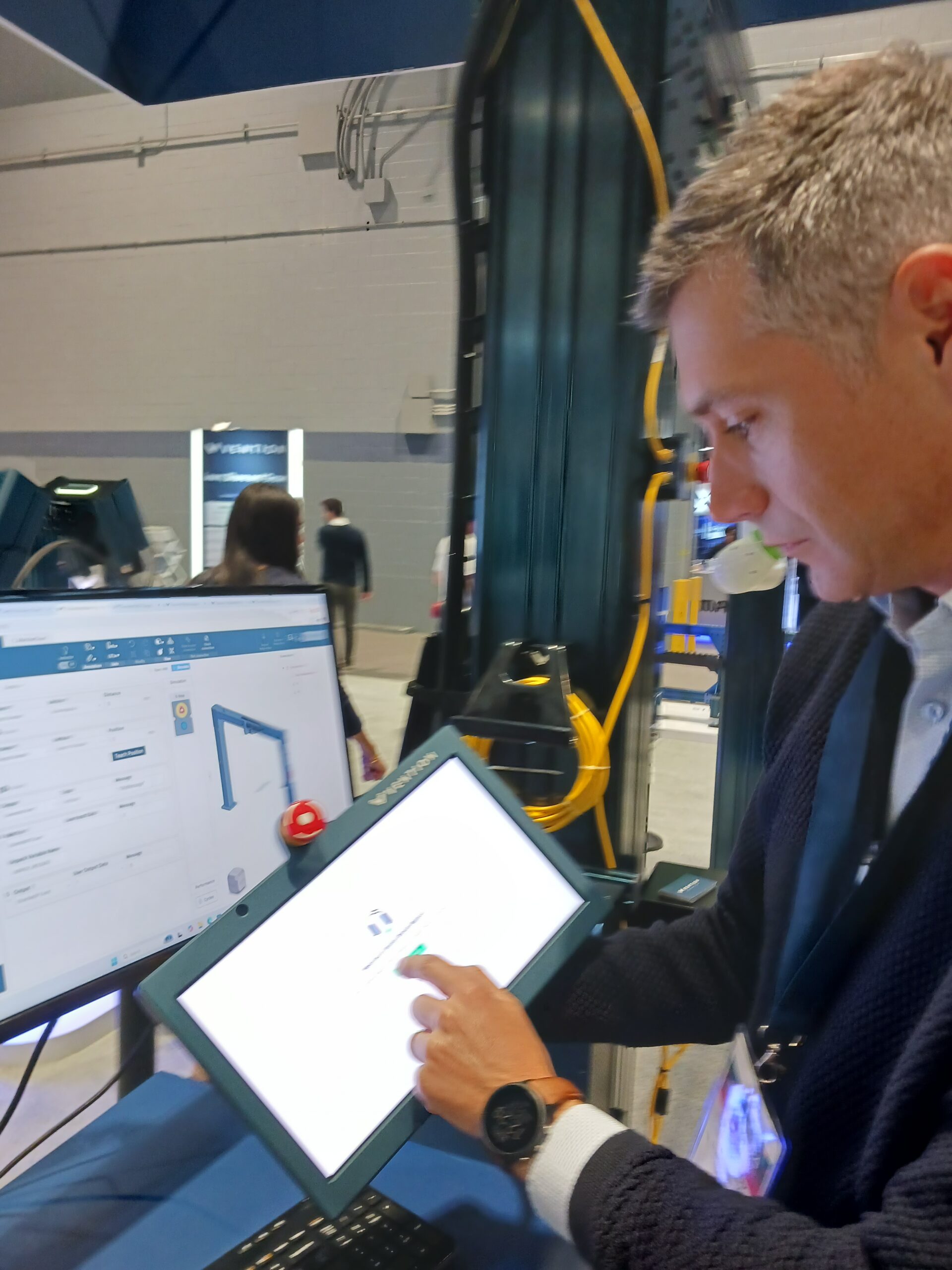

ABB joined the Vention ecosystem, confirming the compatibility between the Vention Manufacturing Automation Platform (MAP) and the ABB GoFa cobot family to allow users to design robotic automation systems online, simplifying the adoption of robotic automaton from the design stage through to operations on the factory floor, as announced and demonstrated at IMTS 2024. At the Vention booth, Control Engineering discussed the collaboration and demonstrated collaborative robots with Etienne Lacroix, founder and CEO of Vention, and Andrea Cassoni, the global head of collaborative robotics and partnerships development with ABB (Figure 1).

Online platform enhances use of robotic automation systems

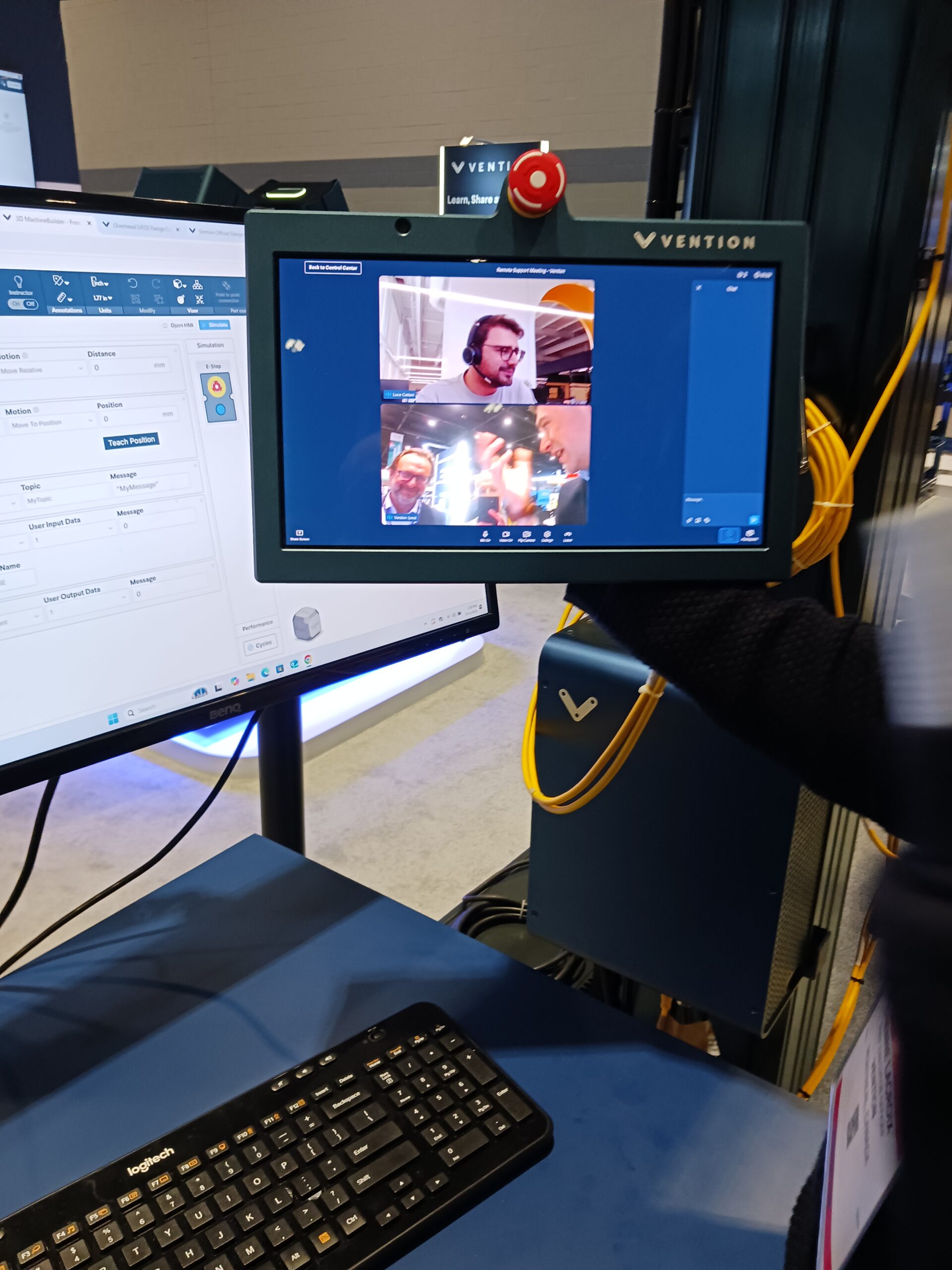

Vention developed the cloud-based MAP to allow users to design robotic automation systems online, simplifying the adoption of robotic automaton from the design stage through to operation on the factory floor. As part of the Vention environment, ABB accesses a broader range of do-it-yourself (DIY) software for automation customers, including Vention MachineBuilder (design), MachineLogic (robot programming), MachineAnalytics (operations, monitoring and data) and Remote Support (on-demand support). Vention enhanced its offerings with ABB’s robotics solutions, with ABB GoFa robots available for the Vention Rapid Series application line “later in 2025.” The relationship is said to expand market reach and innovation opportunities for both companies. Previously, the companies collaborated in other electrification, robotics and discrete automation areas, they said.

Collaborative robot abilities enhanced; design, support services added

In the booth demonstration, Lacroix and Cassoni showed how the coloration can help end users or machine builders more quickly setup (Figure 2) and more efficiently use collaborative robots using services (Figure 3) and live online support as needed (Figure 4 and online services video short).

A Vention-Nvidia collaboration showed how an ABB GoFa collaborative robot uses machine vision enabled by Nvidia and machine vision to locate a tray of parts in a pick-and-place application without fixturing (Lacroix explains in a related video short).

Vention, founded in 2016, helps manufacturers to design, automate, order, deploy and operate automated equipment through the Vention Manufacturing Automation Platform. With more 18,000 machines in than 4,000 factories in more than 25 industries, Vention said it is “democratizing access to industrial automation and robotics, making advanced manufacturing technologies accessible to all.”

ABB GoFa CRB15000 Series collaborative robot is part of the ABB GoFa cobot family with 5kg, 10kg and 12kg payloads.

Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected], wrote this report from interviews and additional materials from the companies.

CONSIDER THIS

Are you getting the help you need with designing, using and supporting collaborative robots in operations?

ONLINE

Learn more from the ABB Robotics & Discrete Automation.

Learn more from Vention.

Learn more from Control Engineering about robotics including this about ABB robots.

Search IMTS 2024 at www.controleng.com to see other developments from the show.