Device-type managers (DTMs) using the new FDT 3.0 standard enables smart manufacturing with common components toolkits in an integrated development environment (IDE) to minimize engineering, simplify DTM certification and shorten time to market.

Learning Objectives

- Device-type managers (DTMs) encapsulates all device-specific data, functions and business rules such as the device structure, its communication capabilities and more.

- The FDT 3.0 standard makes it possible for automation companies to deploy DTM business models.

- FDT 3.0 DTM common components lets device suppliers achieve many important technical and business advantages.

FDT 3.0 specifications support the FDT IIoT Server (FITS) platform, which is designed to enable automation vendors to drive smart manufacturing operations. FDT (IEC 62453) allows integration of devices and networks to engineering tools, such as for industrial control systems (ICS) and asset management systems. FITS security, an OPC Unified Architecture (UA) server for information technology/operational technology (IT/OT) data access and a web server for mobile and remote access, allowing for unified and information-driven business models across the manufacturing sector. The key driver of FDT’s smart manufacturing functionality starts with device-type managers (DTMs) running the new FDT 3.0 standard.

Evolving data-driven, intelligent device solutions

Intended for use with simple and complex devices, the FDT/DTM contains the application software that defines all the parameters and capabilities included in each instrument. The DTM encapsulates all device-specific data, functions and business rules such as the device structure, its communication capabilities, internal dependencies, and its human-machine interface (HMI) structure.

The FDT standard incorporates many DTM types, such as device DTMs, interpreter DTMs, universal DTMs, communications DTMs and gateway DTMs. These DTMs empower a standardized way of communicating, while exchanging information independent of the manufacturer, device type, system, or IT/OT protocol used in applications ranging from small desktop environments to enterprise-wide server/cloud architectures.

Current DTMs automatically make device data and health information available via an OPC UA Server embedded on the FDT Server used in the FDT 3.0 architecture, asset management now is deployable as a cloud service as part of an Industrial Internet of Things (IIoT) or Industry 4.0 initiative. This architecture flattens the automation pyramid so any application requiring data from devices can retrieve it from OPC UA through the DTM.

FDT 3.0 DTMs have further evolved by shifting to Microsoft .NET Core technology and by the user interface (UI) moving to web-based technology, thus diversifying the presentation of asset-related device information. The use of web technology allows server-based distributed architectures to enhance the user experience with mobile and remote access solutions.

Unlike DTMs based on the earlier FDT 1.2 or FDT 2.0 standards, FDT 3.0 DTMs employ responsive touch-screen features as part of HTML 5.0 development, which are mandatory for use with tablets and smart phones. This ensures the interface for today’s mobile devices is integral to the DTM environment.

Using an integrated development environment

With the introduction of the FDT 3.0 standard, FDT Group released associated FDT 3.0 DTM common components toolkits to help the vendor community jump start FDT development with an integrated development environment (IDE). The updated FDT 3.0 DTM common components help minimize engineering effort, simplify DTM certification and shorten time to market.

When DTM common components toolkits were first introduced with the FDT 2.0 standard, the primary purpose was to improve interoperability and help instrumentation companies expedite DTM development activities. This functionality has been enhanced with FDT 3.0 while leveraging decades of recognized industry expertise embedded in the toolkit.

Enhancements to the FDT common components for the FDT 3.0 standard have improved their ease of use for DTM developers. Enhanced toolkit capabilities will benefit companies seeking to differentiate their products from the competition. These features are intended to free DTM development teams to focus on value-added parameter profiles for device functions, web UI and other customized app features.

Platform independence, rigorous security

The enhanced FDT features supported by FDT 3.0 DTM common components include platform independence, an advanced web user interface (UI), auto-enabled OPC UA compatibility, customized graphical parameterization and rigorous DTM security.

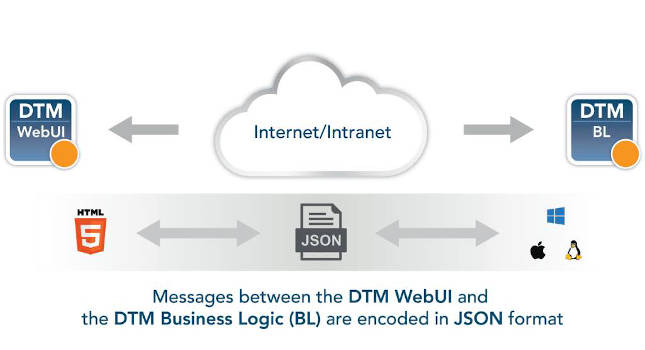

Since FDT 3.0 DTM common components are platform independent – allowing FDT-based solutions to feature cross-platform functionality – they can be used on leading computing platforms such as Apple, Linux and Microsoft Windows. This approach allows users to retain their preferred environment for device firmware manufacturing while ensuring a unified development approach. In addition, the use of web technology now makes it possible to create a true distributed architecture by separating the UI from the server. The client, server and DTMs are all thin and can be hosted on any platform.

The FDT 3.0 DTM common components are essential in driving development initiatives centered around the creation of OPC UA information models. With these tools, OPC UA is auto-enabled for DTMs – meaning no additional coding or work is required. The native integration of OPC UA makes it possible to publish data for a wide range of purposes. This will provide end users with an out-of-the-box solution for accessing DTM information and making it available to cloud-based applications.

The FDT 3.0 standard and its DTM common components support a secure DTM deployment procedure, enabling developers to package and sign DTMs and offer customers the assurance they have been tested and certified by FDT Group. Updated security measures also provide non-repudiation and tamper evidence so users can be confident of the source of their DTMs and know their functionality has not been altered by a third-party.

Deploying smart device business models

From a business perspective, the FDT 3.0 standard makes it possible for automation companies to deploy DTM business models, which leverage the advantages of improved interoperability, native OPC UA support, a modern web UI providing customization and mobile access capabilities, streamlined DTM certification and cloud repository features, and easier developer tools to help reduce time to market for smart DTM-based products.

For example, companies that use FDT 3.0 DTM common components will see reduced cost and effort for DTM development and certification because common components include thousands of lines of prewritten and tested code that ensure DTM base code complies with the FDT standard. The toolkit frees DTM developers from having to write and debug voluminous amounts of their own code. They no longer have to become experts on FDT technology, but rather can focus on enhancing their products with advanced features.

By combining the FDT 3.0 DTM common components with value-added parameter profiles enabling the unique functionality and UI of their device, development teams can move forward with a customized solution without having to learn all the technical nuances of the FDT specification. FDT 3.0 DTM common components help files provide step-by-step instructions for optimizing DTM development activities.

Sample DTMs, common components toolkit

In addition, developers can make use of FDT 3.0 Sample DTMs, which show how to use features and capabilities of the FDT 3.0 DTM common components toolkit. The Sample DTMs include basic functionality that developers can apply as a starting point for creating DTMs.

The common components also assist device suppliers looking to migrate existing FDT DTM 2.0 business logic to support FDT 3.0 applications. This is an important benefit for organizations that are transitioning to FDT 3.0 technology and seeking ways to present DTM information to their customers.

The robust web UI with FDT 3.0 allows DTMs to be opened in any browser, including mobile devices carried by field personnel. Mobility applications are a specific example of where the power of FDT 3.0 DTMs comes into play. Companies can use the technology’s standardized mobility platform as part of their service functionality, helping site engineers solve problems with remote assistance.

FDT 3.0 DTM common components also enable developers to address the majority of the test cases involved in the DTM certification process while eliminating the need to test and verify their own software functions. With the toolkit’s pre-written base code, compliance is auto-enabled, and there is no need to review FDT specifications to implement compliance code.

Rather, developers can customize specific device functionality and web UI code. The FDT 3.0 DTM Common Components also help with development of manifest files and uses an open package format to streamline delivery of DTM packages.

All certified FDT 3.0 DTMs comply with the NAMUR NE-107 recommendation, which stipulates that operators need a view of the process including the status of the instrumentation in a simple and uniform way – regardless of source device – to support predictive maintenance strategies. As such, the DTMs are a crucial enabler for apps intended to view the health of field devices, and subsequently improve maintenance workflows.

Robust DTMs, cloud functions, faster

With the availability of FDT 3.0 DTM common components, and their ability to optimize the development of standardized and compliant DTMs, device suppliers can achieve many important technical and business advantages. First, they can provide a generation of robust DTMs meeting the expectations of their customers. Secondly, they can leverage technology enhancements supporting the era of industrial automation with connected sensor-to-cloud systems in modern industrial facilities. Finally, they can deliver DTMs to market faster and subsequently improve their bottom line.

Robert Hartmann and Dr. Michael Gunzert, CodeWrights. This article originally appeared on FDT Group’s website. FDT Group is a CFE Media content partner. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].

MORE ANSWERS

Keywords: data acquisition, smart manufacturing, IIoT

CONSIDER THIS

What benefits could device-type managers (DTMs) provide to your facility?