By equipping production lines with a strong foundation of sensors and smart devices, companies can improve the availability, performance and quality – and OEE – of their manufacturing operations.

Sensors and smart devices insights

- Data quality is essential for improved performance and reduced downtime.

- Sensors and smart devices provide the foundation for software and controllers to bolster overall equipment effectiveness (OEE).

- Diagnostic tools can help operators pinpoint problems before they cause unplanned downtime.

When it comes to measuring the overall equipment effectiveness (OEE) of a production line, software and controllers are usually the stars of the show. However, sensors and devices are the foundation that set the stage for it. Before operators can use lean software to accurately calculate a plant’s current OEE value and track it over time, sensors and devices must do their part.

Central to factory automation, sensors and smart devices make it possible to gather and aggregate data. Given this critical role, the components selected for a system can help accurately measure downtime, data quality and quantity, system speed and more.

As the formula for OEE is Availability x Performance x Quality, improvement in these three areas can raise the overall OEE value. Here are three ways that incorporating sensors and smart devices can benefit each one.

Improve availability with advanced diagnostic capabilities

Unplanned downtime is the enemy of availability. To minimize it, it’s important to understand the range of measurement capabilities a sensor or device has. Accurate knowledge of when a machine is running – and the reasons it isn’t – is critical for pinpointing which downtime is planned versus unplanned. This can significantly minimize disruption to tight production schedules compared to traditional methods.

A wide range of diagnostics can allow operators to manage their respective application efficiently and identify and diagnose faults as quickly as possible. For instance, placing proximity or limit switches on key machine components can help operators detect running versus stopped states. And power metering modules can detect if a machine is powered or experiencing a fault.

More advanced sensors such as vibration sensors can provide deeper insight into machine status and help predict or prevent unplanned downtime. These sensors go beyond just detecting on/off states; they actively monitor machine health, environment and operational conditions to reduce downtime and optimize maintenance schedules.

Input/output (I/O) devices with diagnostics can help improve availability, too. Some I/O products feature a network adapter with built-in web server and advanced diagnostics. With an integrated web server and advanced diagnostics, failures in the system can be identified remotely, eliminating the need to travel to the machine and making it possible to schedule maintenance to best align with production schedules.

The web server lets operators view diagnostic faults and upgrade firmware over the web, which simplifies start-up and increases availability and productivity without the need for additional tools or software. Additionally, actions can be taken within the application feeding off the diagnostic information.

Improve performance by optimizing production speed and throughput

Achieving a higher level of performance means ensuring machines run at or near their ideal cycle time and produce as many parts as possible during operating time. Sensors and PLCs can play a crucial role in both monitoring and optimizing the speed and throughput of production processes.

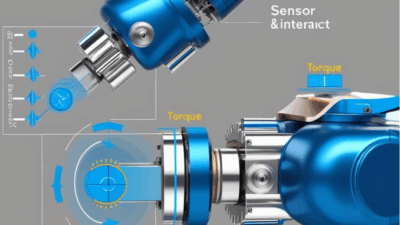

Electric linear actuators, for example, can be precisely controlled through PLC-driven feedback loops using torque or position sensors, ensuring each stroke runs at optimal speed and alignment. This data is fed into Supervisory Control and Data Acquisition (SCADA) or Manufacturing Equipment Systems (MES) for continuous analysis, helping identify and resolve bottlenecks quickly.

Improve data quality by minimizing defects and rework

The data generated by smart solutions used in production lines can be used to ensure that products meet intended specifications and machines are in optimum condition. In this way, the quality and quantity of data collected can influence the product quality.

To improve quality, manufacturers can integrate a range of sensors such as vision systems, laser distance gauges and temperature monitors to detect defects and variations in real time. For example, a vision system may check for surface imperfections on automotive parts or packaged goods.

Airflow sensors are another useful tool for maintaining consistent quality. For instance, in painting or coating processes, proper airflow ensures even application and adherence of paint or powder. This data is fed into a programmable logic controller (PLC) or MES for immediate evaluation, triggering alerts if measurements drift outside specified limits. By analyzing these alerts, operators can better identify and address root causes like incorrect tooling, misalignment or issues with raw materials.

A stronger foundation supports leaner operations

Leaner operations are every manufacturer’s goal. To achieve it, it’s critical that the equipment in production lines operates when scheduled, runs at maximum speed and manufactures products accurately. Sensors and smart devices with advanced diagnostics can help operators quickly address issues to minimize downtime and create feedback loops that optimize throughput and product quality. By equipping production lines with sensors and smart devices, it’s possible for manufacturers to create the strong foundation needed to support ever greater OEE values.

Amit Patel is the director of Portfolio Commercialization at Emerson. Edited by Sheri Kasprzak, managing editor of Automation & Controls with WTWH Media, [email protected].